Isikhunta ngezigaba

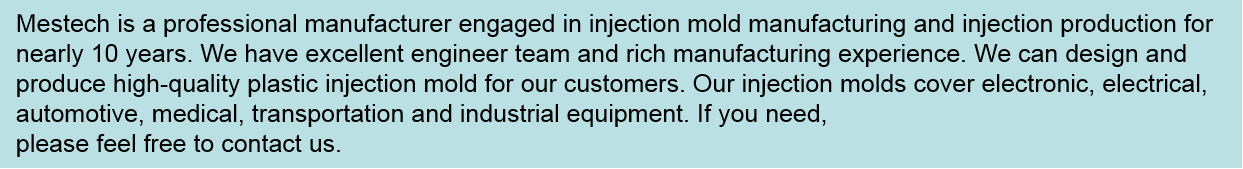

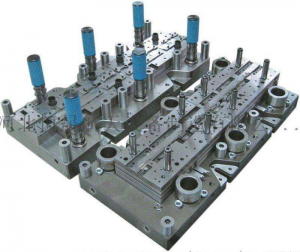

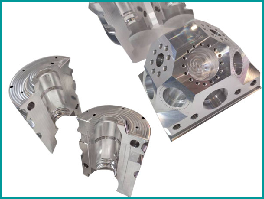

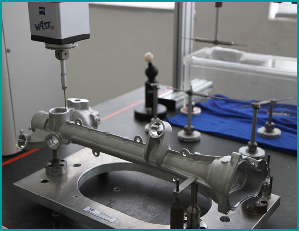

Incazelo emfushane:

Isikhunta (isikhunta, ukufa) ngumndeni omkhulu kakhulu, sidlala indima ebalulekile embonini yanamuhla. Ukuhlukaniswa okucacile kwesikhunta kubaluleke kakhulu ekuqondeni ukukhiqizwa kwezimboni.

Isikhunta (isikhunta, ukufa) iyithuluzi elikhethekile elisetshenziswa emisebenzini yabantu. Isikhunta ngezigabakuhlanganisa anhlobonhlobo. Emphakathini wanamuhla, endala ihlobene kakhulu nokukhiqizwa kwezimboni, okuthuthukisa kakhulu ukusebenza kahle kokukhiqiza nokunemba kwezingxenye.

Isikhunta siyithuluzi elikhethekile elisetshenziswa emisebenzini yabantu. Ukwahlukanisa isikhunta kuhlanganisa anhlobonhlobo. Emphakathini wanamuhla, isikhunta sihlobene kakhulu nokukhiqizwa kwezimboni, okuthuthukisa kakhulu ukusebenza kahle kokukhiqiza nokunemba kwezingxenye.

Isikhunta imishini yezobuchwepheshe ebumba (ubujamo) izinto zibe yimikhiqizo nezingxenye ezinomumo nobukhulu obuthile. Kubandakanya: isitampu sokufa, isikhunta somjovo wepulasitiki, isikhunta sokuphonsa, ukufaka isikhunta, isikhunta se-powder, ukudweba, i-extrusion die, i-rolling die, ingilazi ifa, isikhunta senjoloba, isikhunta se-ceramic, isikhunta sokulingisa nezinye izinhlobo. Embonini yesimanje, isikhunta ikakhulu sibhekisa kusikhunta esisetshenziswa ekukhiqizweni kwezingxenye zepulasitiki nezingxenye zehadiwe. Uma isetshenziselwa ukwakha into eqinile kusuka kupulasitiki oketshezi, insimbi nezinye izinto ezijojowe emgodini wayo, sikubiza ngokuthi "isikhunta" noma "isikhunta". Uma isetshenziselwa ukushaya isibhakela, ukugoba, ukugoba nokukhipha okungenalutho okuqinile, ngokuvamile sikubiza ngokuthi "kufa".

Isikhunta sihlukaniswa ngezici zayo ngokulandelayo:

Ukuhlukaniswa ngezinto zokwenziwa nobuchwepheshe bokucubungula, isikhunta singahlukaniswa nge-hardware die mold, isikhunta sepulasitiki nesikhunta esikhethekile.

(1) Izikhunta ze-metallurgical ezingezona ezensimbi neze-powder: isikhunta sepulasitiki, isikhunta sintering, isikhunta sesihlabathi, isikhunta se-vacuum kanye nesikhunta sikapharafini.

Ngokuthuthuka okusheshayo kweplastikhi yama-polymer, isikhunta sepulasitiki sihlobene kakhulu nezimpilo zabantu. Izikhunta zepulasitiki zingahlukaniswa ngokubanzi zibe: isikhunta somjovo, isikhunta se-extrusion, isikhunta esisizwa ngegesi, njll

(2) Ukufa kwehadiwe kwehlukaniswe: kufa ukusakaza kufa, ukunyathela kufa (njengokushaya isibhakela, ukugoba kuyafa, ukudweba kufa, ukuguqula kufa, ukushwabana kuyafa, ukushisa okufayo, ukushona okufayo, ukubumba kufa, njll.) njengoba kufa ukwakhiwa kufa, ukucasula kuyafa, njll.), Ukufa kuyafa, kufa ukukhipha kufa, ukwakha okokufa, njll.

Metal nginyathela die

1.Classification isikhunta plastic

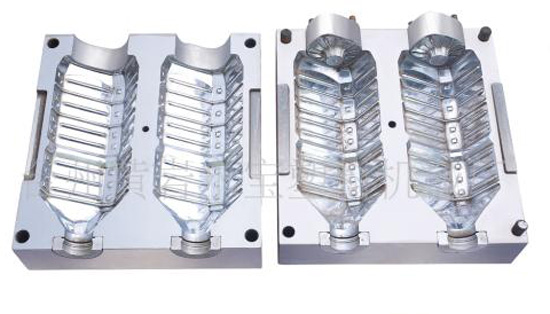

(1) Injection Isikhunta

Injection isikhunta uhlobo isikhunta esetshenziselwa ukwakha izingxenye plastic thermoplastic futhi thermosetting. Umjovo udini is kabanzi ngoba ngokunemba yayo ephezulu kanye nekghono. Umjovo wokubumba ukufaka ipulasitiki emgqonyeni wokushisa womshini wokujova. Ipulasitiki iyashiswa futhi iyancibilika. Iqhutshwa isikulufa noma i-plunger yomshini wokujova, amapulasitiki ajovwa embotsheni yesikhunta ngomlomo nangomshini othululela isikhunta, futhi aqinise futhi abumbe emikhiqizweni yomjovo ngenxa yezenzo zomzimba nezamakhemikhali. Umjovo udini kuyinto umjikelezo ehlanganisa umjovo, ubambe ingcindezi (Ukupholisa) kanye inqubo demoulding izingxenye plastic.Therefore, umjovo udini unezici ngezikhathi.

Umjovo we-Thermoplastic molding unezinzuzo zomjikelezo wokubumba omfushane, ukusebenza kahle kokukhiqiza okuphezulu, ukugqoka okuncane kwezinto ezincibilikisiwe kusikhunta, kanye neqoqo elikhulu lezingxenye zepulasitiki ezinokuma okuyinkimbinkimbi, iphethini ebusweni obucacile nokumaka, nokunemba okuphezulu. Kodwa-ke, ezingxenyeni zepulasitiki ezinoshintsho olukhulu lokujiya kodonga, kunzima ukugwema ukukhubazeka kokubumba. I-Anisotropy yezingxenye zepulasitiki nayo ingenye yezinkinga zekhwalithi. Zonke izinyathelo ezingathathwa kufanele zithathwe ukuyinciphisa.

Umjovo isikhunta

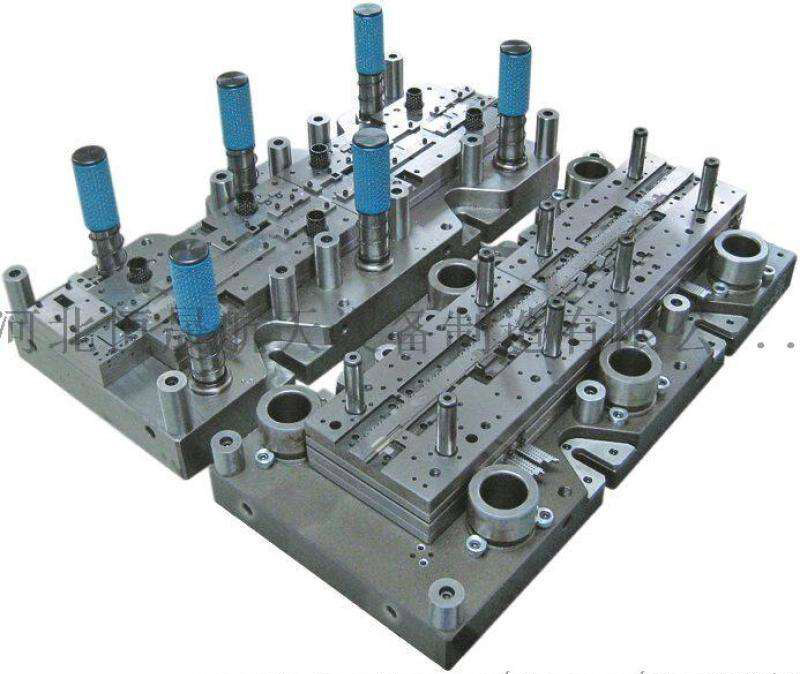

(2) Isikhunta se-extrusion sepulasitiki

Plastic extrusion udini uhlobo ukwakha indlela yokwenza plastic e viscous ukugeleza wombuso kudlule die nge ethize cross-section shape at lokushisa eliphezulu futhi ingcindezi ethile, abese balolonge libe iphrofayli okuqhubekayo edingekayo cross-section shape ezansi izinga lokushisa. Inqubo yokukhiqizwa kwe-extrusion molding ukulungiswa kwezinto zokubumba, i-extrusion molding, ukupholisa ukulungiselelwa, ukudonsa nokusika, ukucubungula ngemuva kwemikhiqizo ekhishwe (ukulungiswa noma ukwelashwa kokushisa). Enkambeni yokukhipha, kufanele kunakwe ekulungiseni izinga lokushisa, isivinini sesikulufu nesivinini sokudonsa kwesigaba ngasinye sokushisa somgqomo nokufa kwe-extruder ukuze kutholakale iphrofayli efanelekile ye-extrusion.

Ukunakekelwa okukhethekile kufanele kukhokhwe ukulungisa isilinganiso se-extrusion se-polymer ncibilika ekufeni. Ngoba lapho isilinganiso se-extrusion sezinto ezincibilikile siphansi, i-extrudate inebuso obushelelezi nomfaniswano wesigaba esiphambanweni, kepha lapho isilinganiso se-extrusion sezinto ezincibilikisiwe sifinyelela umkhawulo othile, ubuso be-extrudate buzoba bukhali futhi bulahlekelwe yinkazimulo, nesikhumba sikashaka, ikhasi eliwolintshi, ukuguqulwa kwesimo nezinye izinto zizovela. Lapho isilinganiso se-extrusion sanda ngokuqhubekayo, ingaphezulu le-extrudate lizohanjiswa, lize ligatshulwe futhi liphulwe libe izingcezu ezincibilikayo noma amasilinda. Ngakho-ke, ukulawulwa kwezinga le-extrusion kubaluleke kakhulu.

Umugqa wokukhiqiza we-Plastic extrusion

Ukufa kwe-extrusion

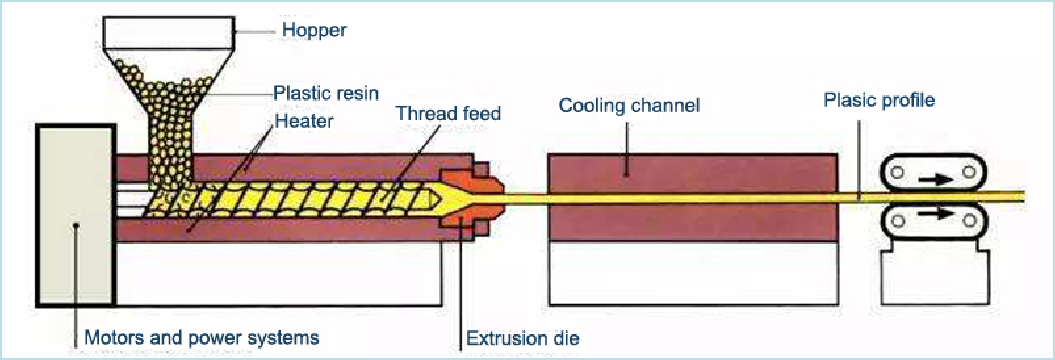

(3) elingenalutho ukwakha isikhunta

Isikhunta sokwakha okungenalutho sifaka i-extrusion blow molding hollow ukwakha kanye nomjovo wokugaya ukubumba okuyize okwenza izinhlobo ezimbili zokubunjwa

Ukubumba okungenalutho kuyindlela yokucubungula elungisa i-tubular noma ishidi elingenalutho elenziwe yi-extrusion noma umjovo futhi lisesimweni seplastikhi kusikhunta sokubumba, ujove ngokushesha umoya ocindezelweyo, uphoqelele okungenalutho ukunweba futhi unamathele odongeni lwe isikhunta umgodi, futhi udilivwe ngemuva kokupholisa nokuphothula, ukuze uthole imikhiqizo edingekayo engenalutho.

Amapulasitiki afaneleka ekubumbeni okuyize ingcindezi ephezulu ye-polyethylene, ingcindezi ephansi ye-polyethinyl, i-polyvinyl chloride eqinile, i-polyvinyl chloride ethambile, i-polystyrene, i-polypropylene, i-polycarbonate, njll. umjovo igalelo udini. Ubuhle be-extrusion blow molding hollow ukwakha ukuthi isakhiwo se-extruder ne-extrusion blow molds silula. Okubi ukuthi ukushuba kodonga lweparison akuhambelani, okudala kalula ukujiya kodonga okungalingani kwemikhiqizo yepulasitiki. Isibalo esifanele ngumdwebo ohleliwe wesimiso sokwakheka kwe-extrusion blow moldollow.

Umjovo igalelo udini unenzuzo iyunifomu odongeni ukushuba futhi akukho onqenqemeni ezindizayo. Ngenxa yezansi ekubunjweni komjovo, phansi komkhiqizo oyize ngeke kukhiqize umthungo wokusika, ongemuhle kuphela kepha namandla amakhulu. Okubi ukuthi imishini nesikhunta esisetshenzisiwe kuyabiza, ngakho-ke le ndlela yokwakha isetshenziswa kakhulu ekukhiqizweni kwemikhiqizo emincane engenalutho, futhi ayisetshenziswa kabanzi ekusetshenzisweni kwendlela yokuqumba engenalutho yokwenziwa kwe-extrusion.

Umjovo igalelo udini plastic

Isikhunta esivunguzayo

(4) Die ekubunjweni isikhunta plastic

Izikhunta ze-Die casting zibizwa nangokuthi isikhunta sokudlulisa Izinto zepulasitiki zengezwa egumbini lokupholisa elifudumeziwe, bese ingcindezi isetshenziswa kukholomu yengcindezi. Ipulasitiki iyancibilika ngaphansi kokushisa okuphezulu nengcindezi, bese ingena emgodini ngohlelo lokusakaza isikhunta, kancane kancane lukhuni futhi lwenze. Le ndlela ukwakha ibizwa die-ekubunjweni ukwakha, futhi isikhunta esetshenziswa ibizwa ngokuthi die-ekubunjweni udini. Lolu hlobo lwesikhunta lusetshenziselwa kakhulu ukwakha i-thermosetting plastic.

(5) kokucindezelwa Isikhunta

Ukuminyanisa ukubumba kungenye yezindlela zokuqala zokubumba zezingxenye zepulasitiki. Ukuminyaniswa okwenziwa ukufaka amaplastiki ngqo embotsheni evulekile yokushisa ngethempelesha ethile, bese uvale idizili. Ngaphansi kwesenzo sokushisa nengcindezi, ipulasitiki liyancibilika libe yindawo yokugeleza. Ngenxa yesenzo somzimba namakhemikhali, amapulasitiki aqiniswa aba izingxenye zepulasitiki ezinesimo esithile nosayizi ekamelweni lokushisa. Ukucindezela ukubumba kusetshenziselwa ukubumba amapulasitiki e-thermosetting, njenge-phenolic molding powder, i-urea formaldehyde ne-melamine formaldehyde powder powder, ingilazi yefayibha eqinise amaplastiki e-phenolic, i-epoxy resin, i-DAP resin, i-resin ye-silicone, i-polyimide njalonjalo. Ingabumba futhi icubungule i-polyester aggregates (i-DMC) engasetshenzisiwe, amapulasitiki okubumba amashidi (i-SMC), ukuhlelwa kwangaphambili. Amapulasitiki wokubumba we-Monolithic (BMC) njll. Ngokuvamile, ukwakheka okuhambisanayo kokufa okuphezulu nangaphansi kwefilimu yokuminyanisa kuvame ukucindezelwa, futhi ukucindezelwa kokufa kuhlukaniswe ngezinhlobo ezintathu: uhlobo lokuchichima, uhlobo olungachichimi nohlobo lokuchichima okungatheni.

(6) Ingcindezi ekubunjweni die

Eyaziwa nangokuthi i- die casting. Izinto zepulasitiki zengezwa ekamelweni lokushaja elifudumeziwe, bese ikholomu ecindezelayo ifakwa egumbini lokushaja ukukhiya i-die. Ingcindezi isetshenziswa kupulasitiki ngokusebenzisa ikholomu yokucindezela. Ipulasitiki liyancibilika libe yindawo egeleza ngokushisa okuphezulu nokucindezela okukhulu, bese liqina emgodini kancane kancane ngohlelo lokuthela. Le ndlela yokwakha ibizwa nangokuthi ukudlulisa ukubumba. Ingcindezi yomjovo wengcindezi ilungele amapulasitiki aqinile anezindawo ezahlukahlukene zokuncibilika. Empeleni, ingasetshenziswa kokucindezelwa udini noma ingcindezi umjovo udini. Kodwa-ke, lapho ukushisa kokuqina kungaphansi kwezinga lokuqina, isimo sokuncibilika sinokufudumala okuhle, futhi lapho izinga lokuqina liphakeme, izinga lokuqina liphakeme.

2. Ukwahlukaniswa kwehadiwe kuyafa

Ngokuya ngemishini nenqubo yendawo, isikhunta sensimbi singahlukaniswa sibe isikhunta esishisayo esisebenzayo nesikhunta sokusebenza esibandayo. Umehluko phakathi kwabo mkhulu.

1) Zezıhlabane ukusebenza die: hot hot die die libhekisela die efanelekayo deformation ezishisayo zensimbi, ezifana extrusion ashisayo die, die ekubunjweni die, hot ekwakheni die, hot hot ecasulayo, njll Njengoba ashisayo die die usebenza ngaphansi lokushisa okuphezulu nengcindezi ephezulu isikhathi eside, izinto zokufa ziyadingeka ukuze zibe namandla aphezulu, ubulukhuni nokuqina kokushisa, ikakhulukazi amandla aphezulu wokushisa, ukukhathala okushisayo, ukuqina nokuqina kokugqoka. Ifaka ikakhulukazi:

A. Insimbi yokufa isakaza isikhunta: inqubo ukujova insimbi yokushisa ephezulu encibilikisiwe engxenyeni yokufa ukuthola izingxenye zesakhiwo ezidingekayo. Metal die casting is used to make complex shape parts of aluminium alloy, zinc alloy, magnesium alloy and other non-ferrous alloys.

B. Isikhunta sopering yensimbi yensimbi: inqubo ukwenza impuphu yensimbi ibe sesimweni esithile nosayizi we-billet esikhunjeni, bese ishisisa i-billet iye esimweni sokuncibilika, ukuze ikwazi ukwakheka. Ukukhishwa kwensimbi yensimbi kusetshenziselwa insimbi engagqwali, i-titanium, ithusi, i-iron, i-nickel nezinye izingxenye zokushisa eziphezulu.

C. Ukufa okushisayo okushisayo kwensimbi: ukusebenza okushisayo okushisayo kwe-extrusion die kuvame ukusebenza ekucutshungweni kwe-aluminium, i-magnesium, insimbi nezinye izinsimbi endaweni ephezulu yokushisa, futhi ukwakheka kwesigaba sezingxenye ezikhiqizwayo kuhlala kungashintshiwe. I-hot extrusion die iyadingeka ukuze ibe nokumelana nokushisa okuhle nokumelana nokushisa.

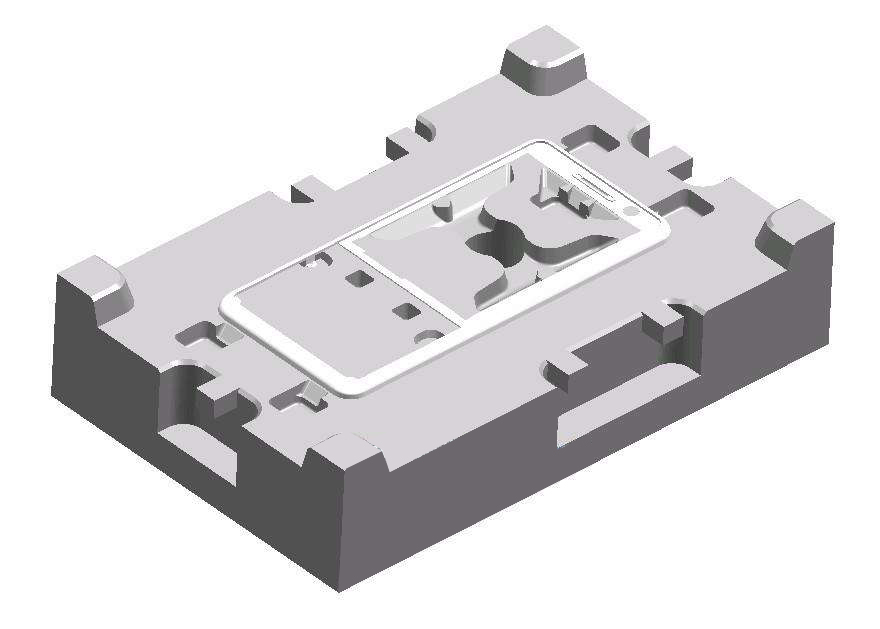

Metal die ekubunjweni isikhunta

I-Hot extrusion die ne-aluminium profile

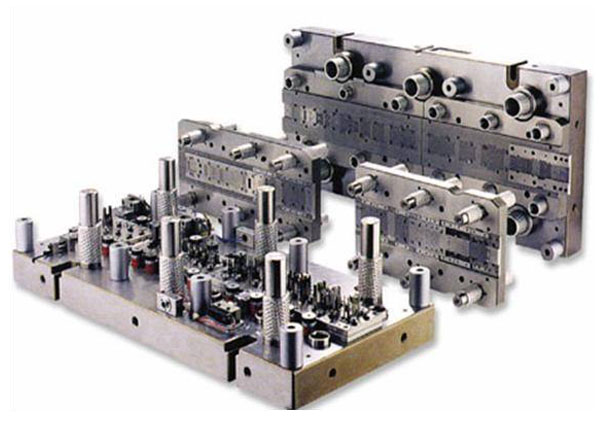

2) Ukufa okubandayo kuyafa (Ukunyathela kuyafa): ukusebenza okubandayo kuyafa kufela ukusebenza ekamelweni lokushisa, okuvame ukubizwa ngokuthi ukufakwa kwesitampu (okufana nokushaya isibhakela, ukugoba kuyafa, ukudweba kuyafa, ukujika kuyafa, ukuncipha kuyafa, ukugoqa kuyafa, ukuqhuma kuyafa , ukubumba kuyafa, njll.). Ingxenye yokusebenza yomshini obandayo osebenzayo ngokuvamile idinga ukuthwala ingcindezi enkulu, amandla okugoba, amandla okuthelela nomfutho wokuxabana, ngakho ukumelana ne-deformation kukhulu kakhulu.

A. Ukufa kwensimbi kungenzeki: insimbi yokuvala insimbi isetshenziselwa ukusika ukwakheka okubili ngocwecwe lwensimbi. Izingxenye zingasetshenziswa futhi njengokungenalutho kokugoba, ukudweba nokwakha. Blanking ikakhulukazi esetshenziselwa blanking, isibhakela futhi ukusika yensimbi, insimbi engagqwali, aluminium ingxubevange, ithusi ingxubevange namanye amapuleti.

B. Ukugoba okugoqayo: ingxenye esebenzisa udonga ukugoba amapuleti, imigoqo kanye nezigaba zibe i-engeli ethile, ukugobeka nokuma. Ifanele insimbi, insimbi engagqwali, ingxubevange ye-aluminium nezingxenye zethusi.

C. Ukudweba okufayo: ukudweba kuyinqubo yokugxiviza, ukudweba indandatho noma insimbi yokuguqula izinto zensimbi zibe izingxenye zezilinda noma zebhokisi. Ukudweba i-die kuyithuluzi elijwayelekile lokudweba.

D. Ukwenza i-die: ukusebenzisa i-die ukwakha kuyindlela yokukhiqiza ukuthi ukusikeka kwepulasitiki kwenziwa kuqinile ngenkathi ikhwalithi nezinto zayo zihlala zingashintshiwe. I-E.Riveting die: i-riveting yensimbi iyindlela yokuxhuma ubuciko bokusebenza obuphakathi nendawo ngomsebenzi ophakathi ngamandla. Ngokuvamile, i-riveting isetshenziswa phakathi kwamapuleti acabalele. Idayisi elisetshenziswe kule nqubo libizwa ngokuthi i-riveting die.

Ukugoba kufa

Metal nginyathela die

Ukusetshenziswa kwesikhunta noma ukufa:

(1). Imikhiqizo ye-elekthronikhi neyokuxhumana;

(2). Imishini yehhovisi;

(3). Izingxenye ezisele zemoto;

(4). Imishini yasendlini;

(5) Imishini kagesi;

(6). Ukuvikelwa kwezokwelapha nezemvelo;

(7). Izikhungo zezimboni;

(8) .Ukuhlakanipha okungelona iqiniso;

(9). Ezokuthutha;

(10). Izinto zokwakha, ikhishi nezinto zangasese namathuluzi;