Ungazakha kanjani izingxenye zepulasitiki

Incazelo emfushane:

Ku ukuklama izingxenye zepulasitikiUkuchaza ukwakheka, usayizi nokunemba kwezingxenye, ngokuya ngendima edlalwa yizingxenye kumkhiqizo, kanye nomthetho wenqubo yokubumba kwepulasitiki. Umphumela wokugcina yimidwebo yokukhiqizwa kwesikhunta nengxenye yepulasitiki.

Ukukhiqizwa komkhiqizo kuqala ngokudizayina. Idizayini yezingxenye zepulasitiki inquma ngqo ukugcwaliseka kwesakhiwo sangaphakathi, izindleko nomsebenzi womkhiqizo, futhi inquma nesinyathelo esilandelayo sokukhiqizwa kwesikhunta, izindleko nomjikelezo, kanye nenqubo yokubumba umjovo kanye nenqubo yokucubungula ngemuva kanye nezindleko.

Izingxenye zepulasitiki zisetshenziswa kabanzi emikhiqizweni ehlukahlukene, ezikhungweni nasezimpilweni zabantu emphakathini wanamuhla. Izingxenye zepulasitiki zidinga ubujamo obuhlukile nemisebenzi. Basebenzisa izinto zepulasitiki futhi izakhiwo zabo ziyahlukahluka. Ngasikhathi sinye, kunezindlela eziningi zokwenza izingxenye zepulasitiki embonini. Ngakho-ke ukuklama izingxenye zepulasitiki akuwona umsebenzi olula.

Ukwakheka okuhlukile kwengxenye nezinto kukhiqizwa ukucubungula okuhlukile. Ukucubungula ukubumba ipulasitiki ikakhulu kufaka ngezansi:

1.umjovo udini

2.blowing udini

3.compression ukubumba

Ukubunjwa 4.rotational

5.formmorming

6.ukuqedwa

7.ukubumba

8.ukushisa amalangabi

Kunezindlela eziningi zokuzikhiqiza ngobuningi. Inaliti udini kuyinto ethandwa yokukhiqiza indlela, ngoba umjovo wabumba 50% ~ 60% izingxenye plastic akhiqizwa byb umjovo udini, kuba ngejubane ukukhiqizwa khono.

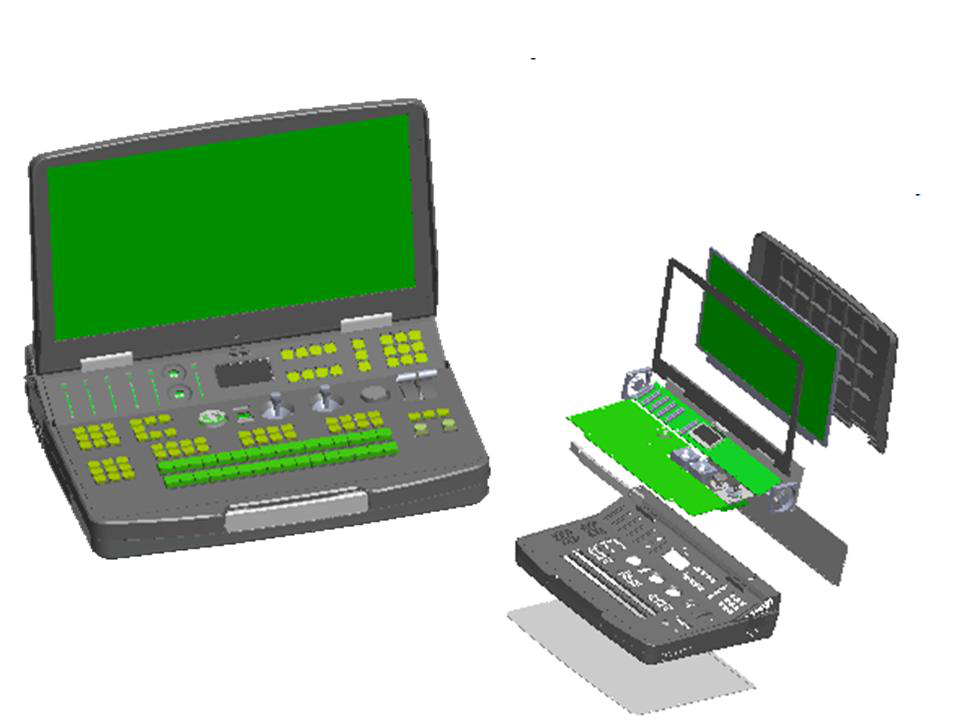

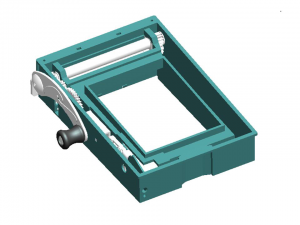

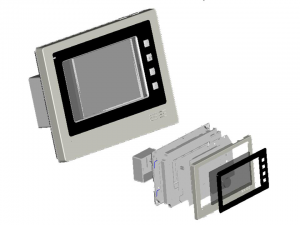

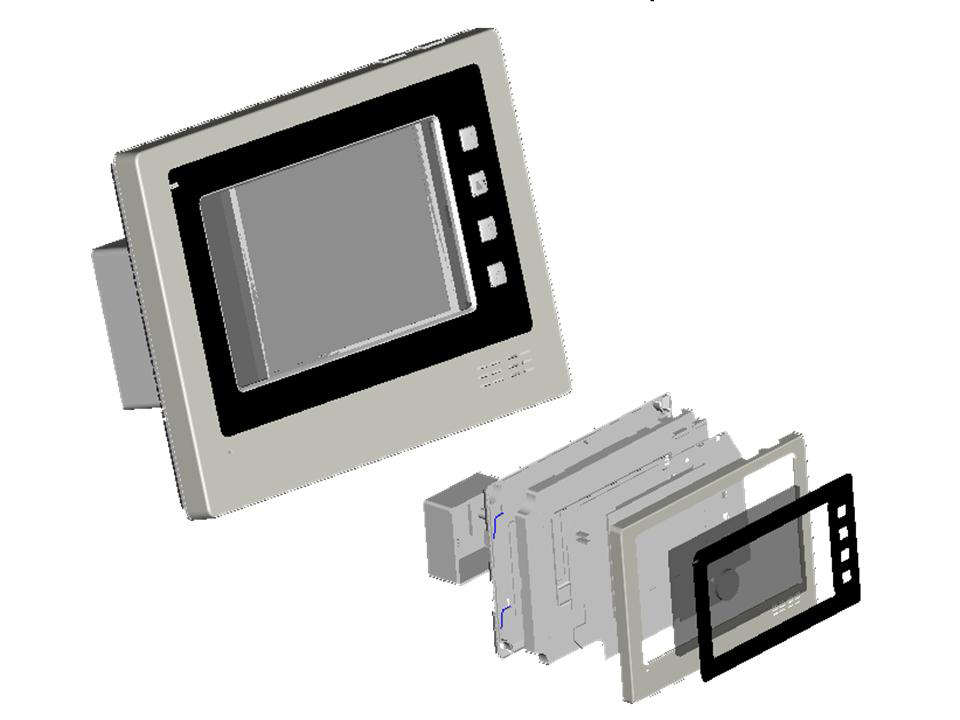

Khombisa ikesi lezingxenye ezithile zepulasitiki esiziklanyile:

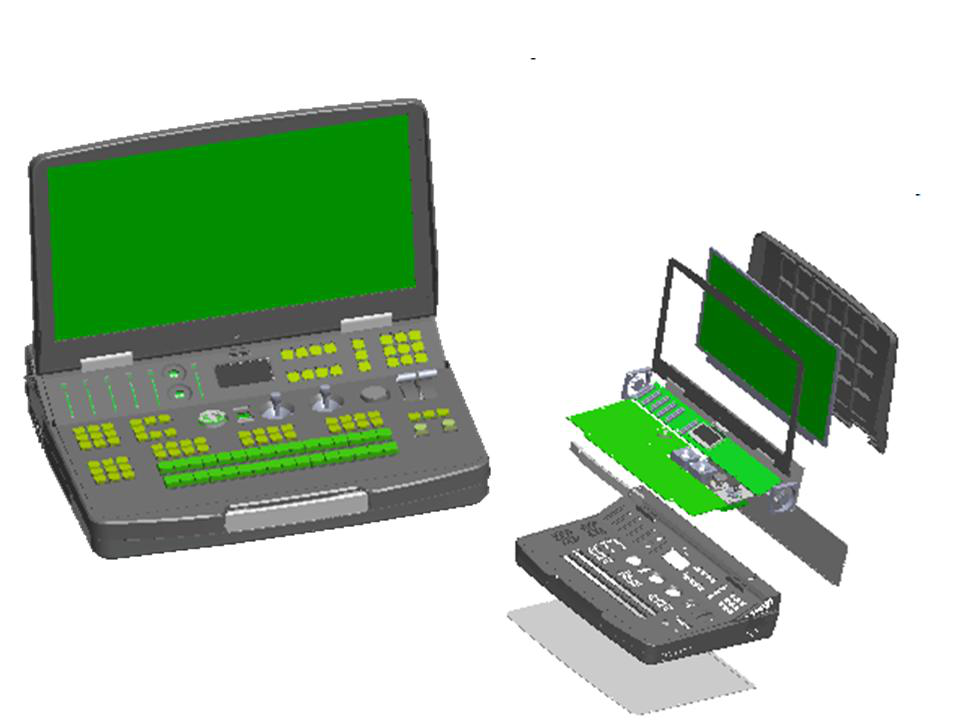

Indawo ebiyelwe ngeplastiki yefoni yombono

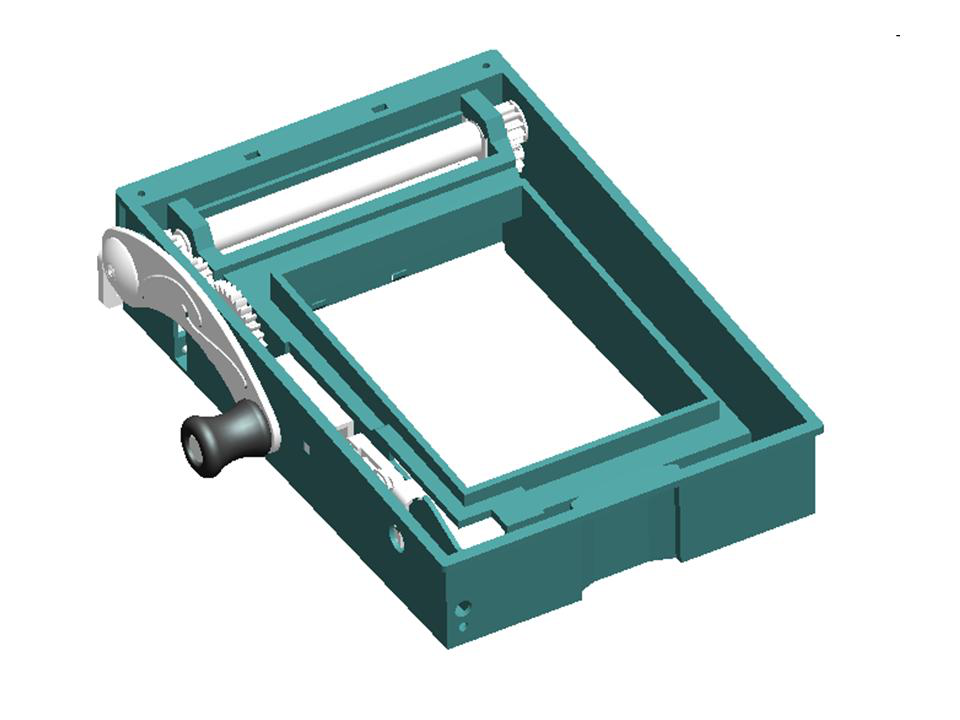

Izingxenye Plastic of mshini

Amacala epulasitiki kagesi

Izindlu zepulasitiki zensimbi

Ngezansi sabelana ngemininingwane yokuthi zingakhiwa kanjani izingxenye zepulasitiki ezicini ezintathu

* Amathiphu ayi-10 wezingxenye zepulasitiki zokwakha okufanele wazi

1.Qala ukubukeka komklamo nosayizi womkhiqizo.

Lesi yisinyathelo sokuqala kuyo yonke inqubo yokwakhiwa. Ngokuya ngocwaningo lwezimakethe nezidingo zamakhasimende, thola ukubonakala nokusebenza kwemikhiqizo, bese wenza imisebenzi yokuthuthukisa umkhiqizo.

Ngokomsebenzi wokuthuthuka, iqembu lokuthuthukisa liqhubeka nokuhlaziywa kobuchwepheshe nobuchwepheshe kumkhiqizo, futhi lakhe imodeli yokubukeka komkhiqizo we-3D. Ngemuva kwalokho, ngokuya ngokuqaphela ukusebenza nomhlangano womkhiqizo, izingxenye ezingaba khona ziyahlelwa.

2.Separate izingxenye ngazinye kusuka imidwebo yomkhiqizo, khetha plastic uhlobo resin for izingxenye plastic

Lesi sinyathelo ukuhlukanisa izingxenye kusuka kumodeli ye-3D etholwe kusinyathelo esedlule bese uziklama njengabantu ngabodwana. Ngokuya ngezidingo zomsebenzi zezingxenye, khetha izinto ezifanelekile zepulasitiki noma izinto zokwakha. Isibonelo, i-ABS ivame ukusetshenziswa kufayela le-

igobolondo, i-ABS / BC noma i-PC iyadingeka ukuthi ibe nezakhiwo ezithile zomshini, izingxenye ezisobala ezifana ne-lampshade, i-lamp post PMMA noma i-PC, igiya noma izingxenye zokugqoka i-POM noma iNylon.

Ngemuva kokukhetha ukwaziswa kwezingxenye, ukwakheka kwemininingwane kungaqalwa.

Chaza ama-engeli okusalungiswa

Ama-engeli okusalungiswa avumela ukususwa kwepulasitiki kusikhunta. Ngaphandle kwama-engeli okusalungiswa, ingxenye izonikeza ukumelana okukhulu ngenxa yokungqubuzana ngesikhathi sokususwa. Ama-engeli okusalungiswa kufanele abekhona ngaphakathi nangaphandle kwengxenye. Ukujula kwengxenye, kukhula i-engeli esalungiswa. Umthetho olula wesithupha ukuthi ube ne-1 degree okusalungiswa engela nge-intshi. Ukungabi nayo i-engeli eyanele kungadala ukusikwa ezinhlangothini zengxenye kanye / noma amamaki amakhulu we-ejector pin (ngaphezulu kulokhu kamuva).

Ama-engeli okusalungiswa wangaphandle: Ukujula kwengxenye, kukhula i-engeli yokusalungiswa. Umthetho olula wesithupha ukuthi ube ne-1 degree okusalungiswa engela nge-intshi. Ukungabi nayo i-engeli eyanele kungadala ukusikwa ezinhlangothini zengxenye kanye / noma amamaki amakhulu we-ejector pin (ngaphezulu kulokhu kamuva).

Imvamisa, ukuze ubukeke kahle, ukuthungwa kwenziwa ebusweni bezingxenye. Udonga olunokuthungwa lukhuni, ukungqubuzana kukhulu, futhi akulula ukulususa emgodini, ngakho-ke kudinga i-angle enkulu yokudweba. Ukuthungwa okunamandla, i-engeli enkulu yokubhala edingekayo.

4.Define udonga ukushuba / iyunifomu ukushuba

Ukubunjwa okuqinile akufuneki ekubunjweni komjovo ngenxa yezizathu ezilandelayo:

1) .Isikhathi sokupholisa silingana nesikwele sobukhulu bodonga. Isikhathi sokupholisa eside sokuqina sizokwehlula umnotho wokukhiqizwa ngobuningi. (umqhubi wokushisa ompofu)

2) Isigaba esijiyile sincipha ngaphezu kwesigaba esincanyana, ngaleyo ndlela sethula umehluko wokuncipha okuholela ku-warpage noma kumaki wokumaka njll (izici zokuncipha zepulasitiki nezici ze-pvT)

Ngakho-ke sinomthetho oyisisekelo wokuklanywa kwengxenye yepulasitiki; ngangokunokwenzeka udonga ukujiya kufanele kube iyunifomu noma kube njalo ngokusebenzisa ingxenye. Lokhu kushuba kodonga kubizwa ngokuqina kobukhulu begama.

Uma kunesigaba esiqinile engxenyeni, kufanele senziwe umgodi ngokwethula i-core. Lokhu kufanele kuqinisekise ukujiya kodonga okufanayo nxazonke.

3) .Yikuphi ukubhekelwa kokunquma ubukhulu bodonga?

Kufanele kube mkhulu futhi siqine ngokwanele ukwenza umsebenzi. Wall ukushuba kungaba 0.5 kuya 5mm.

Kumele futhi ibe mncane ngokwanele ukuze ipholise ngokushesha, okuholele ekutheni isisindo sengxenye ephansi kanye nokukhiqiza okuphezulu.

Noma ikuphi ukwehluka kobukhulu bodonga kufanele kugcinwe ubuncane ngangokunokwenzeka.

Ingxenye yepulasitiki enobukhulu obuhlukahlukene bodonga izobhekana namazinga okupholisa ahlukile nokuncipha okuhlukile. Esimweni esinjalo ukuthola ukubekezelelana okusondele kuba nzima kakhulu futhi kungenzeki izikhathi eziningi. Lapho ukwehluka kobukhulu bodonga kubalulekile, ushintsho phakathi kwalokhu okubili kufanele lube kancane.

Idizayini ye-5.Connection phakathi kwezingxenye

Imvamisa sidinga ukuxhuma amagobolondo amabili ndawonye. Ukwakha igumbi elibiyelwe phakathi kwabo ukubeka izingxenye zangaphakathi (inhlangano ye-PCB noma indlela yokwenza).

Izinhlobo ezijwayelekile zokuxhuma:

1). Izingwegwe zokuthwebula:

Ukuxhuma izingwegwe kwe-Snap kuvame ukusetshenziswa emikhiqizweni yosayizi omncane naphakathi. Isici sayo ukuthi izingwegwe ze-snap ngokuvamile zibekwa emaphethelweni wezingxenye, futhi usayizi womkhiqizo ungenziwa ube mncane. Lapho ihlanganisiwe, ivalwa ngqo ngaphandle kokusebenzisa noma yimaphi amathuluzi anjenge-screwdriver, i-ultrasonic welding die namanye. Okubi ukuthi izingwegwe ze-snap zingadala isikhunta sibe nzima kakhulu. Umshini wesilayida nomshini wokuphakamisa kuyadingeka ukubona ukuxhumana kwe-hook snap nokwandisa izindleko zesikhunta.

2). Izindwangu zesikulufa:

Izikulufu zokuqina ziqinile futhi zithembekile. Ikakhulukazi, i-screw + nut fixation inokwethenjelwa kakhulu futhi ihlala njalo, ivumela ukuhlukaniswa okuningi ngaphandle kwemifantu. Ukuxhuma kwesikulufa kufanelekile ngemikhiqizo enamandla amakhulu okukhiya nokuqaqa okuningi. Okubi ukuthi ikholomu yesikulufa ithatha isikhala esithe xaxa.

3). Abaphathi abaphezulu:

Ukuxhuma abaphathi ukuxhumana ukulungisa izingxenye ezimbili ngokuhlangana okuqinile phakathi kwabaphathi nezimbobo. Le ndlela yokuxhuma ayinamandla ngokwanele ukuvumela ukuqaqa imikhiqizo. Okubi ukuthi amandla okukhiya azokwehla njengoba isikhathi sokuqaqa sikhula.

4). Ukushisela kwe-Ultrasonic:

Ukushisela kwe-Ultrasonic ukubeka izingxenye ezimbili kusikhunta se-ultrasonic nokuxuba indawo oxhumana nayo ngaphansi kwesenzo somshini wokushisela we-ultrasonic. Usayizi womkhiqizo ungaba mncane, isikhunta somjovo silula, futhi ukuxhumana kuqinile. Okungalungile ukusetshenziswa kwesikhunta se-ultrasonic nomshini we-welding we-ultrasonic, usayizi womkhiqizo awukwazi ukuba mkhulu kakhulu. Ngemuva kokuqaqa, izingxenye ze-ultrasonic azikwazi ukusetshenziswa futhi.

6.Undercuts

Ama-undercuts yizinto eziphazamisa ukususwa kwengxenye yesikhunta. Ukusikwa kungabonakala cishe noma kuphi kumklamo. Lokhu nakho akwamukelekile, uma kungenjalo kubi kunokungabikho kwe-engeli esalungiswa engxenyeni. Kodwa-ke, okunye okusikwayo kuyadingeka futhi / noma kungenakugwenywa. Kulezo zimo, kudingekile

ama-undercuts akhiqizwa ngokuhambisa / ukuhambisa izingxenye kusikhunta.

Gcina ukhumbula ukuthi ukudala okusikwayo kubiza kakhulu lapho kukhiqizwa isikhunta futhi kufanele kugcinwe okungenani.

7.Support Ribs / Gussets

Izimbambo ezingxenyeni zepulasitiki zithuthukisa ukuqina (ubudlelwano phakathi komthwalo nengxenye yokuphambuka) kwengxenye futhi kukhuphule ukuqina. Iphinde ithuthukise ikhono lesikhunta njengoba isheshisa ukuncibilika kokugeleza kuya ngasebambo.

Izimbambo zibekwa eceleni komkhombandlela wengcindezi enkulu nokuphambuka ezindaweni ezingabonakali zengxenye. Ukugcwaliswa kwesikhunta, ukuncipha kanye nokukhishwa kufanele futhi kube nomthelela ezinqumweni zokubekwa kwezimbambo.

Izimbambo ezingahlangani nodonga oluqondile akumele ziphele ngokungazelelwe. Ukudlulela kancane kancane odongeni lwamagama kufanele kunciphise ubungozi bokuhlushwa kwengcindezi.

Ubambo - ubukhulu

Izimbambo kufanele zibe nobukhulu obulandelayo.

Ubuningi bezimbambo kufanele bube phakathi kuka-0.5 kuye ku-0.6 izikhathi eziqanjiwe zodonga ukugwema usinki.

Ukuphakama kobambo kufanele kube ubukhulu obungu-2,5 kuya kwezi-3 bokuqina kodonga.

Ubambo kufanele lube ne-0.5 kuya ku-1.5-degree okusalungiswa engela ukwenza lula ukukhishwa.

Isisekelo sobambo kufanele sibe ne-radius engu-0,25 kuye ku-0.4 izikhathi ubukhulu bokuqina kodonga.

Ibanga phakathi kwezimbambo ezimbili kufanele libe izikhathi ezi-2 kuye kwezingu-3 (noma ngaphezulu) ukuqina kodonga okuzibiza.

Amaphethelo we-Radiused

Lapho izindawo ezimbili zihlangana, zakheka ikona. Ekhoneni, ukujiya kodonga kukhuphuka kube izikhathi eziyi-1.4 ubukhulu bokudonga okuzibiza. Lokhu kubangela ukuncipha kokuhlukaniswa nokucindezelwa okubunjiwe nesikhathi sokupholisa eside. Ngakho-ke, ingozi yokwehluleka enkonzweni iyanda emakhoneni abukhali.

Ukuxazulula le nkinga, amakhona kufanele ashelele nge-radius. Irediyasi kufanele inikezwe ngaphandle nangaphakathi. Ungalokothi ube nekhoneni langaphakathi elibukhali njengoba likhuthaza ukuqhekeka. Irediyasi kufanele ibe ngaleyo ndlela yokuthi iqinisekisa umthetho wobukhulu bodonga njalo. Kukhethwa ukuba nobubanzi obungu-0.6 kuye ku-0.75 ukuphakama kodonga emakhoneni. Ungalokothi ube nekhoneni langaphakathi elibukhali njengoba likhuthaza ukuqhekeka.

Umklamo we-9

Sihlala sisebenzisa izikulufo ukulungisa amacala amabili uhhafu ndawonye, noma sibophele i-PCBA noma ezinye izingxenye ezingxenyeni zepulasitiki. Ngakho-ke abaphathi besikulufa bayisakhiwo sokugoqa izingxenye ezilungisiwe.

Umphathi wesikulufa umise okwe-cylindrical. Umphathi angaxhunyaniswa ngesisekelo nengxenye yomama noma ingaxhunywa eceleni. Ukuxhuma ohlangothini kungaholela esigabeni esiwugqinsi sepulasitiki, esingathandeki ngoba singadala uphawu lokucwila futhi sandise isikhathi sokupholisa. Le nkinga ingaxazululwa ngokuxhumanisa umphathi ngobambo odongeni lohlangothi njengoba kukhonjisiwe kumdwebo. IBoss ingenziwa iqine ngokunikeza izimbambo zezinqa.

Isikulufa sisetshenziswa kumphathi ukubopha enye ingxenye. Kukhona uhlobo lwentambo olwenziwe ngezikulufo nohlobo lokunyathela lwezikulufo. Izikulufo zokwenza imicu zisetshenziswa kuma-thermoplastics nezikulufo zokusika imicu zisetshenziswa ezingxenyeni zepulasitiki ze-inelastic thermoset.

Izikulufu ezakha izintambo zikhiqiza imicu yabesifazane odongeni lwangaphakathi lwabaphathi ngokugeleza okubandayo - ipulasitiki ikhubazeke endaweni kunokuba isikwe.

Isikulufa umphathi kufanele abe nobukhulu obufanele ukumelana namandla okufakwa kwesikulufu nomthwalo obekwe ku-screw ekusebenzeni.

Usayizi we-bore ohlobene nesikulufu kubalulekile ekumelaneni nokuhlulwa kwentambo nokukhishwa kwesikulufa.

Ububanzi obungaphandle beBoss kufanele bube bukhulu ngokwanele ukumelana nengcindezi eyindilinga ngenxa yokwakheka kwentambo.

I-Bore inobubanzi obukhudlwana ekungeneni kwekhefu ubude obufushane. Lokhu kusiza ekutholeni isikulufa ngaphambi kokushayela. Kubuye kunciphise izingcindezi ekugcineni komphathi.

Abakhiqizi bePolymer banikeza imihlahlandlela yokunquma ubukhulu bomphathi ngezinto zabo. Abakhiqizi bezikulufu babuye banikeze imihlahlandlela yosayizi ofanele wesibhobo sesikulufu.

Ukunakekelwa kufanele kuthathwe ukuze kuqinisekiswe amalunga we-weld aqinile azungeze isikulufa esizalela umphathi.

Ukunakekelwa kufanele kuthathwe ukugwema ukucindezelwa okubunjiwe kubaphathi njengoba kungahluleka ngaphansi kwemvelo enolaka.

Ukuboreka kubasi kufanele kube kujule kunokujula kwentambo.

Umhlobiso we-10

Kwesinye isikhathi, ukuze sikwazi ukubukeka kahle, sivame ukwenza ukwelashwa okukhethekile ebusweni bepulasitiki.

Njenge: ukuthungwa, ukucwebezela okuphezulu, ukudweba kwesifutho, ukuqoshwa kwe-laser, ukunyathela okushisayo, i-electroplating nokunye. Kuyadingeka ukuthi ucabangele ekwakhiweni komkhiqizo ngaphambi kwesikhathi, ukugwema ukucubungula okwalandela kungafinyelelwa noma izinguquko zosayizi ezithinta ukuhlangana komkhiqizo.