Isibonelo sepulasitiki

Incazelo emfushane:

Ngemikhiqizo yepulasitiki edinga ukukhiqizwa kwesikhunta, imvamisa senza okuthile ngokomzimba isibonelo sepulasitikiukuqinisekisa ukwakheka kwayo. Kushiwo imodeli eyodwa noma eziningana ezenziwayo ezenziwe ngokuya ngomdwebo wokubukeka komkhiqizo noma umdwebo wesakhiwo ngaphandle kokuvula isikhunta ukuhlola ubuhlakani bokubukeka noma isakhiwo. Isibonelo seplastiki ezindaweni ezahlukahlukene saziwa nangokuthi isampula lepulasitiki, imodeli, i-mackup.

I-plastic prototype iyindlela ebalulekile yokuhlola ukwakheka komkhiqizo nemikhiqizo yokubonisa. Kususelwa kwimidwebo yomklamo womkhiqizo, kusetshenziswa ukucubungula ithuluzi lomshini noma ukwelashwa kwe-resin laser noma inqubo yokubopha ukukhiqiza amasampula wokuhlola ukwakheka nokubonisa. Lapho siklama umkhiqizo omusha, amasampula avame ukwenziwa ngokuya komkhiqizo noma imidwebo yesakhiwo ukuhlola ukubukeka noma ukwakheka okunengqondo kwezifanekiso ezisebenzayo. Ukwenza i-prototype kungenye yezindlela eziphumelela kakhulu zokuqinisekisa ukwakheka komkhiqizo nokunciphisa ubungozi bokukhiqiza.

Ngenhloso yokuhlinzeka ngendlela ephumelela kunazo zonke yokwenza uhlobo lwakho lwethuluzi, onjiniyela bethu bezokwakha balapha ukukunikeza umklamo wensiza yokwenza ukuqinisekisa ukuthi imikhiqizo yakho ihlala ilungele umakhi womkhiqizo wepulasitiki. Ngokuhlaziywa okuphelele nokukhethwa kwempahla ethile, singaqinisa ukuthembela kwephrojekthi yakho futhi sinikeze insizakalo yokuphrinta esheshayo ukuncoma ukwakhiwa- lokhu kunikeza amathuba amaningi okuhlolwa kokusebenza okuzogqamisa noma yikuphi ukuguqulwa okungenzeka okudinga ukwenziwa ekwakhiweni ukuze kuhambisane kahle nezidingo zakho zemakethe. Lokhu kuqinisekisa ukuthi izingqinamba zokwakhiwa komkhiqizo azingeni esigabeni sokulandelela sokukhiqizwa kwesikhunta, ukugwema ukwehluleka sekwephuzile kanye nemfucuza enkulu yezindleko. Emikhiqizweni emikhulu yezimboni, noma ngabe yimikhiqizo eyinkimbinkimbi ye-elekthronikhi, izinto zikagesi, izimoto, izinsimbi zokwelapha, amabhulashi wamazinyo, izinkomishi zamanzi nezinye izidingo ezilula zansuku zonke, esigabeni sokwakhiwa komkhiqizo, isampula lesibonelo kufanele lenziwe ukuhlola nokuqinisekisa ukusebenza kobuchwepheshe, ubuchwepheshe nezici zemakethe, futhi zithuthukisa njalo ukwakheka kokusebenzisa kahle. Thola imiphumela emihle kakhulu.

Izinhlobo nokusetshenziswa kwama-prototypes epulasitiki

1. Ukubukeka kwesibonelo: Ekuqaleni kwesigaba esisha sokuklanywa komkhiqizo, yenza uhlobo lokubukeka lokuhlola nokuthuthukisa ukwakheka kokubukeka komkhiqizo okuhlukile, bese ukhetha uhlelo lokubukeka oluhle kakhulu futhi oluhehayo kumakhasimende.

2. Uhlobo lwesakhiwo:Ngemuva kokuthi ukwakheka kwesakhiwo somkhiqizo sekuqediwe, imodeli uqobo lwenziwa ngokuya ngomdwebo wesakhiwo ngaphambi kokukhiqizwa kwesikhunta. Umklami uhlola isakhiwo sokwakheka kwesakhiwo ukuthola ukuthi yikuphi ukukhubazeka ekwakhiweni kusengaphambili, futhi athuthukise futhi enze ngcono ukwakheka, ukuze kugwenywe ubungozi ekukhiqizeni.

Isibonelo esisebenzayo: Ngokuphendula izidingo zamakhasimende noma izidingo zokuphromotha imakethe, uhlobo lwangaphambili luboniswa emakethe nakumakhasimende ngaphambi kokwenziwa kwesikhunta noma isikhunta singakaqedwa.

Ukubukeka / uhlobo lwesakhiwo

Uhlobo olusebenzayo

Isibonelo sokwakhiwa

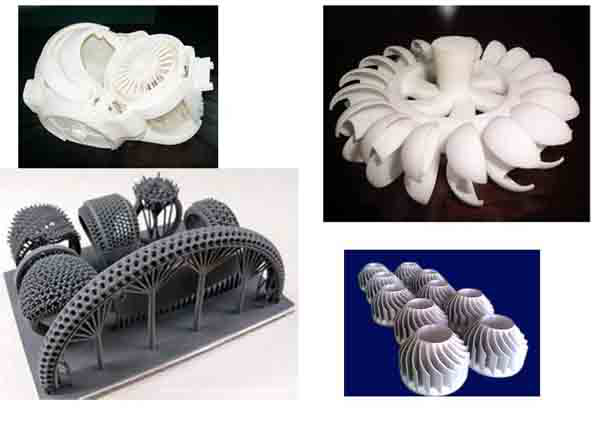

Kunobuchwepheshe obuyisihlanu obuyinhloko bokwenza ama-prototypes epulasitiki njengokulandelayo

CNC Machining prototypes epulasitiki

1. CNC Machining:Isibonelo senziwa ikakhulukazi yisikhungo sokusika. Ngokubhekiswa kumdwebo wokuklanywa komkhiqizo, okokusebenza okungafuneki kususwa kokungenalutho okuqinile kwepulasitiki ngokusika ithuluzi kuthuluzi lomshini wokusika, futhi izingxenye ezihambisana nosayizi nomumo ziyatholakala. Ngemuva kokucubungula kwe-CNC, okunye ukucubungula okwenziwa ngesandla kuyadingeka.

--- Inzuzo: izingxenye zingenziwa ngezinto ezahlukahlukene ngokuya ngesidingo; izingxenye ezenziwe zinokunemba okuhle, amandla futhi akukho ukuphazamiseka; kulula ukuthola ikhwalithi ephezulu yendawo, kulula ukuyipenda, ukuphrinta electroplating nokuphrinta kwesikrini. Ifanele amasampula anokuhlangana komhlangano, izingxenye ezihambayo, izingxenye ezinkulu, izingxenye ezinokubukeka kokuhlobisa, nemishini esebenzayo. Isikhathi sokuthumela: izinsuku ezingu-7-8. Ifanele ukwenza ukubukeka kwesibonelo, uhlobo olusebenzayo nohlobo lwesakhiwo.

--- Izinto: ABS, PC, POM, PMMA, inayiloni, njll

--- Ububi: Ububi yisidingo senani elithile lokucubungula ngesandla, izindleko eziphezulu. Lapho isakhiwo siyinkimbinkimbi ngokwengeziwe, izindleko ziyanda.

2. SLAnoma stereolithography Prototyping - Ubuchwepheshe be-SLA buqinisa ungqimba olulodwa ngokuchayeka kwe-laser. Ngokusebenzisa i-ultraviolet laser beam, ngokwesigaba esinqunyiwe esinqunyiwe soqweqwe lwangempela, iphulukisa iphuzu ngephuzu, ukusuka kwephoyinti kuya kolunye, kusuka kulayini kuya phezulu, ngokuhamba kwepulatifomu yokuphakamisa, ukuphrinta ngakuthathu kuqedwa ngokubeka ungqimba ngongqimba . Lesi sibonelo sisuswe ethangini futhi saqiniswa ngaphansi kwesibani se-ultraviolet. Ngokuya ngobunzima, usuku lokulethwa lungaba mfushane njengezinsuku ezingama-2-3.

Ama-prototypes we-SLA epulasitiki

3. I-SLSnoma ukukhetha i-laser sintering. Lokhu kufaka ukwakhiwa kwezakhi kusuka kudatha ye-3D kusetshenziswa izimpushana ze-resin nama-lasers. Ibanga lomjovo elenziwe lingasetshenziswa ukuhlinzeka ngokusebenza okuthile, kufaka phakathi izinto ze- "hinge eshukumayo". Idethi yokulethwa ingaba yizinsuku ezingu-2-3, kuye ngobunzima. Ngesikhathi sintering senqubo ye-SLS, izinga lokushisa kwempahla eyimpuphu (noma isibopho sayo) isivele ifike endaweni yokuncibilika, futhi ayikwazi ukugeleza kahle futhi igcwalise igebe phakathi kwezinhlayiya ze-powder. Ngakho-ke, ubuso bengxenye bukhululekile futhi bunzima.

--- Izinzuzo: Amandla amahle, akulula ukukhubazeka, ukumelana nomthelela, angamelana nesisindo nenani elithile lemishini. Kulula ukubopha. Corrosion ukumelana. Kufanelekile ukwenza uhlobo lwesakhiwo.

--- Izinto: Kusetshenziswa i-nylon powder, i-polycarbonate powder, i-acrylic polymer powder, i-polyethylene powder, i-nylon powder exutshwe ne-50% ubuhlalu beglasi, i-elastomer polymer powder, i-ceramic noma insimbi ne-binder powder nezinye izinto, ukuqhathanisa ukusebenza.

--- Okumbi: ukunemba okuntekenteke kobuso kanye nekhwalithi yendawo. Isetshenziselwa uhlobo lwesakhiwo okungadingeki ikhwalithi ephezulu yokubukeka.

4. Umshini ovimbelayo(Ukugcwalisa Umshini) Ukukhiqizwa kabusha komshini kuyindlela yokwenza amamodeli amancane weqoqo. Isebenzisa uhlobo lwangempela (i-CNC prototype noma i-SLA prototype) ukwenza i-silica gel isikhunta ku-vacuum, futhi isebenzisa izinto ze-PU ukuthululela i-vacuum, ukuze ikwazi ukufanisa into efanayo ne-prototype yasekuqaleni, enokuqina kokushisa, amandla nobulukhuni ukwedlula uhlobo lokuqala. Uma amakhasimende adinga amasethi amaningi noma amaningi, kufanelekile ukusebenzisa le ndlela, eyehlisa kakhulu izindleko.. Izinto zokwakha zingahlinzeka ngezinto zokwenziwa ezahlukahlukene ukufeza ezinye zezici zezingxenye zokujola zomjovo. Usuku lokulethwa lungaba yizinsuku eziyi-7-10, kuya ngobunzima.

--- Izinzuzo: Kuyadingeka ukusebenzisa inqubo ye-CNC noma ye-SLA ukwenza isampula yoqobo, efanelekile kumasethi amaningana kumasethi amaningi amaqoqo amancane amasampuli. Usayizi ukuzinza, amandla nokuqina kuphakeme kune-SLA prototype, eduze ne-CNC prototype. Ifanele ukwenza ukubukeka kwesibonelo. Prototype esebenzayo kanye ne-prototype yesakhiwo.

--- Izinto: I-PU resin isetshenziswa kakhulu, kepha futhi ingahlinzeka ngezinto zokwenziwa ezahlukahlukene.

--- Ububi: Azifanele izingxenye ezinesimo esiyinkimbinkimbi. Intengo ingaphansi kwaleyo yamasampula e-CNC.

5. I-RIM (Reaction Injection Molding) kubuye kusetshenziswe uhlobo lwangempela (i-CNC prototype noma i-SLA prototype) eyenziwe ngesikhunta se-silica gel, uketshezi olunezinto ezimbili i-polyurethane PU lujojowe kwisikhunta esisheshayo ekamelweni lokushisa nasendaweni yengcindezi ephansi, ukuphulukisa nokuthunyelwe -ucubungula ukuthola amasampula epulasitiki adingekayo.

--- Izinzuzo: Isetshenziselwa ukuphindaphindeka okuncane kwe-batch yamaphaneli alula futhi amakhulu nokukhiqizwa kwemikhiqizo yokujiya enkulu ebanzi futhi engalingani. Inezinzuzo zokusebenza kahle okuphezulu, umjikelezo wokukhiqiza omfushane, inqubo elula nezindleko eziphansi .-- Izinto: Izinto ezimbili ze-polyurethane PU.

--- Ububi: Izinto ezisetshenzisiwe azishadile.

Prototype ebusweni ukwelashwa: wokucwebezelisa, ukupenda, usilika ukuphrinta, gilding, electroplating.

Inqubo ngayinye yokuphrinta esheshayo inganikela ngezindlela ezahlukahlukene zokuqedwa kwesikhunta namasu okudweba, ukuze kwakheke ukubukeka kobuchwepheshe. Kulesi sigaba, onjiniyela bethu bangancoma ezinye izinketho ezisheshayo zokusebenzisa amathuluzi ukuze kutholakale umkhiqizo ojabulisa kakhulu futhi osebenzayo. Njengesevisi yokumisa okukodwa, sikunikeza uchungechunge lwezinsizakalo, njengokuklanywa komkhiqizo, ukwenza prototyping, ukucubungula isikhunta kanye nokujova ngomjovo, imishini, nomhlangano womkhiqizo. Ungomunye wemisebenzi ukukunikeza amasampula wesampula wezingxenye zepulasitiki nezensimbi. Kumjikelezo wakho wokuthuthukiswa komkhiqizo, ngosizo lwethu oluphelele, singaqinisekisa ukuthi imikhiqizo yakho ingena emakethe ngendlela esebenza kahle futhi engambi eqolo.

Ukuhlolwa kwesibonelo kuyingxenye ebalulekile yokwakhiwa komkhiqizo. IMestech futhi inikela ngomklamo womkhiqizo, ithuluzi lesikhunta, ukubumba ngomjovo wepulasitiki nezinsizakalo zomhlangano womkhiqizo ukuxhasa inqubo yakho yokukhiqiza.