Metal nginyathela isikhunta

Incazelo emfushane:

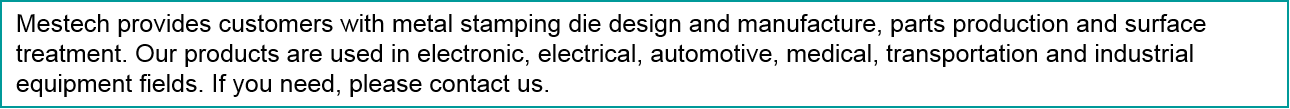

Metal nginyathela isikhunta uhlobo lwamathuluzi nemishini wokushaya ishidi izingxenye zensimbi. Inezinzuzo zokukhiqiza okuphezulu nokusebenza komjikelezo wokukhiqiza omfushane. Kuvame ukusetshenziselwa ukukhiqizwa ngobuningi.

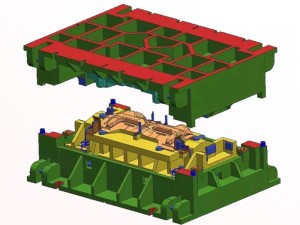

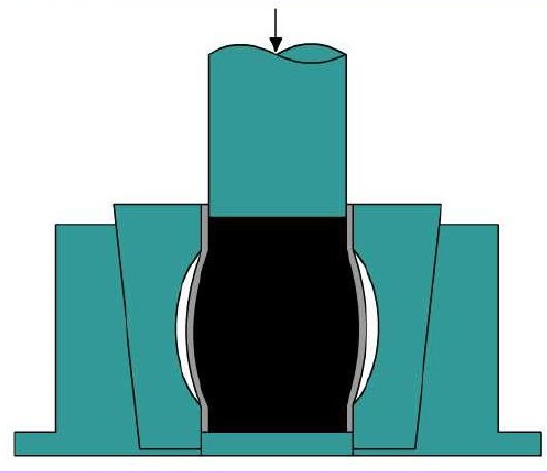

Metal nginyathela isikhunta(Metal nginyathela die) uhlobo ekhethekile inqubo imishini okuyinto icubungula izinto (metal noma okungezona-metal) zibe izingxenye (noma imikhiqizo semi-siphelile) inqubo abandayo nginyathela. Ibizwa ngokuthi yi-cold stamping die (eyaziwa kakhulu ngokuthi yi-cold stamping die). Ukunyathela isikhunta sokufa kuyisikhunta esisebenza ngokubandayo. Ekamelweni lokushisa, i-die efakwe emshinini isetshenziselwa ukufaka ingcindezi kokuqukethwe ukukhiqiza ukwahlukana noma ukusikeka kwepulasitiki, ukuze kutholakale izingxenye ezidingekayo.

Izingxenye zensimbi ezinyathela ingxenye enkulu yezingxenye zensimbi, ezifana necala lekhompyutha, igobolondo le-aluminium, ikhava yezinsimbi, ibhokisi lamathuluzi, isitsha, ubakaki, ikhava yehawu, i-wire terminal nokunye. Wokushaya die kuyinto uhlobo mass ukukhiqizwa die, okuyinto has izinhlobo eziningi. Ukufa kwesitampu kuvame ukuhlukaniswa ngokwezakhiwo zenqubo nokwakhiwa kokufa

Ukuhlukaniswa ngokuya ngenqubo yezakhiwo

(1) (1) I-blanking die iyidayi esetshenziselwa ukuhlukanisa izinto ohlangothini oluvaliwe noma oluvulekile. Ezifana blanking die, isibhakela die, ukusika die nokunye.

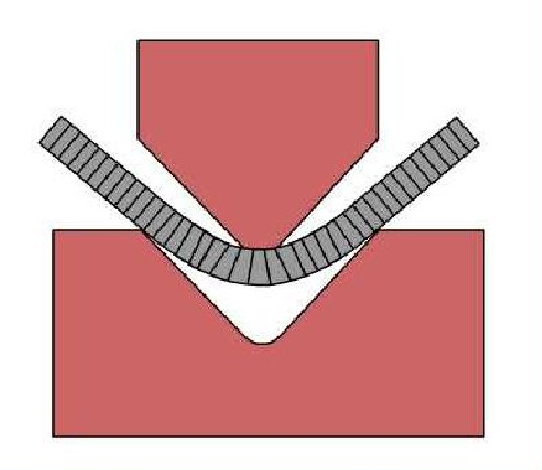

(2) I die eguqa kwenza blank noma ezinye blank umkhiqizo eguqa ukusonteka kanye umugqa oqondile (eguqa ijika), ukuze athole engela ethile futhi ukuma isikhunta workpiece.

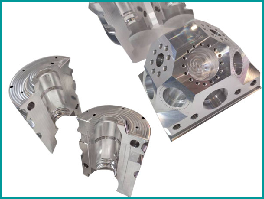

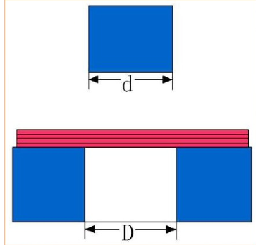

(3) Ukudweba okufayo kungukufa okungenza kungabi nalutho engxenyeni evulekile engenalutho noma ukwenza ingxenye engenalutho yokushintsha ukuma nosayizi ngokuqhubekayo.

(4) I-die ukwakha uhlobo lokufa olungakopisha ngokuqondile umsebenzi ongenalutho noma oqediwe ngokuya ngesimo se-punch ne-die, kuyilapho ukwaziswa uqobo kukhiqiza ukusikeka kwasendaweni kwepulasitiki. Njengokufa okujiyile, ukugoqa okufayo, ukukhulisa okufayo, ukugoqa okwenziwe, ukugoqa okufayo, ukubumba okufayo, njll.

(5) I-Riveting die ukusebenzisa amandla angaphandle ukwenza izingxenye zihlangane noma zihlangane ngokuhlelekile nangendlela ethile, bese zakha ngokuphelele.

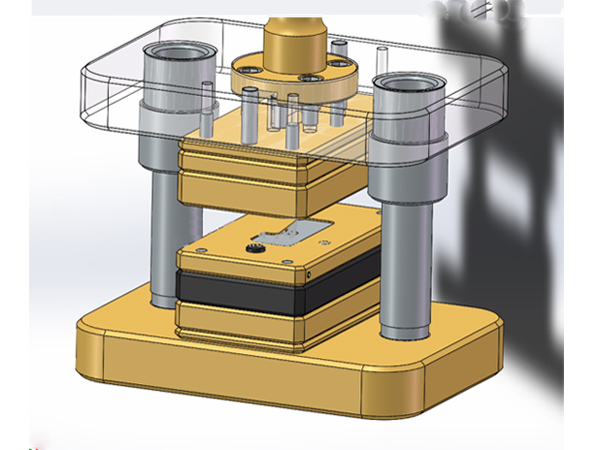

Ukushaya isibhakela

Ukudweba die

Ukugoba kufa

Ukufa okuqhamukayo

Ukuhlukaniswa ngokuya ngezinga lenhlanganisela yokusebenza

(1) Ukufa okukodwa (isigaba kufa)

Kokushaywa okukodwa kwabezindaba, kuphele inqubo eyodwa yokushaya isitampu.

Kunesiteshi esisodwa kuphela esisebenzayo kanye nenqubo yokusebenza eyodwa yokufa kwenqubo yokusebenza eyodwa. It ingahlukaniswa blanking die, eguqa die, umdwebo die, turning die futhi ekubumbeni die.

Ukwenza ukwenziwa kulula futhi izindleko zokwenza okufile ziphansi. Kukufanele ukukhiqizwa kwezingxenye ezinesakhiwo esilula nokukhipha okuphansi. Ukusebenza kahle kokukhiqiza kanye nezindleko eziphezulu zokukhiqiza.

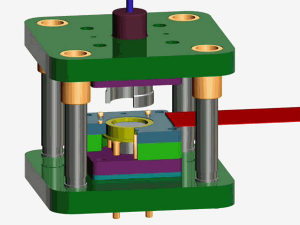

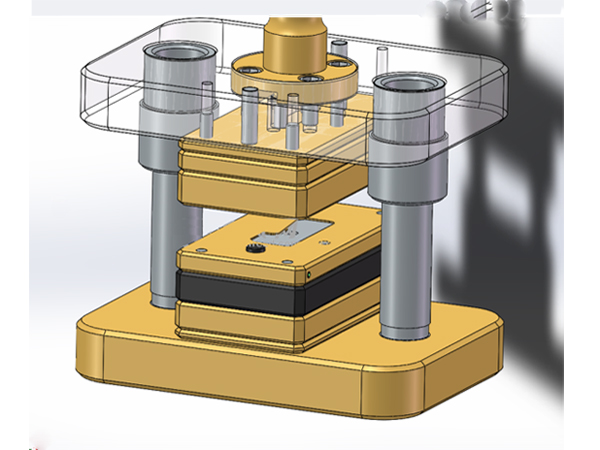

(2) die nginyathela die (gang die)

Umuntu ofayo onendawo eyodwa yokusebenza, oqeda izinqubo ezimbili noma ngaphezulu zokugwaza endaweni efanayo yokusebenza kokushaywa ngabezindaba okukodwa.

I-compound die ifanelekile ukwenza izingxenye zensimbi ezinesakhiwo esiyinkimbinkimbi nokunemba okuphezulu kokuma. Isikhunta siyinkimbinkimbi futhi sinembile, futhi izindleko zokwenza isikhunta siphezulu.

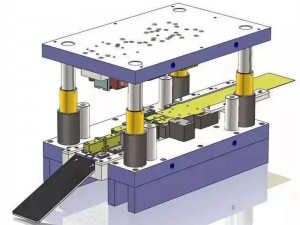

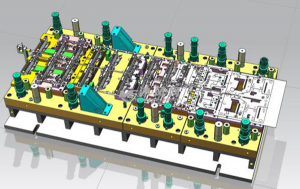

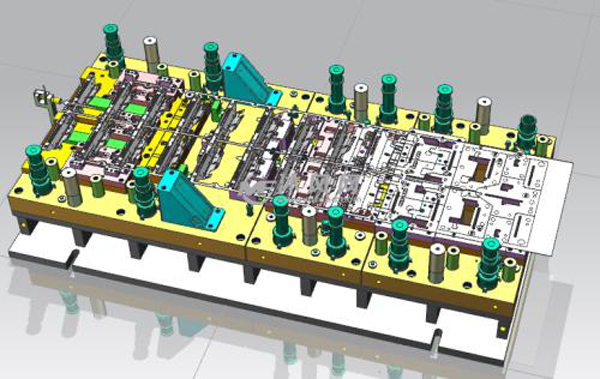

(3) Ukuqhubeka kokunyathela okufayo (okubizwa nangokuthi isikhunta esiqhubekayo)

Ekuqondisweni kokudla okungenalutho, kuneziteshi ezimbili noma ngaphezulu. Kokushaywa okukodwa komshini, izinqubo ezimbili noma ngaphezulu zokugwaza ziyaqedwa eziteshini ezihlukene ngamunye ngamunye.

Izici zokufa okuqhubekayo zingokulandelayo:

Ukusebenza kahle kokukhiqiza okuphezulu: ukufa okuqhubekayo kungaqedela ukunyathela, ukugoba, ukugoba, ukudweba, ukwakha ngakuthathu nokuhlangana kwezingxenye eziyinkimbinkimbi, ukunciphisa ukudluliswa okuphakathi nokuma okuphindaphindwayo. Ngaphezu kwalokho, ukwanda kwenani leziteshi akukuthinti ukusebenza kahle kokukhiqiza, futhi kungenza izingxenye ezincane kakhulu zokunemba. Kulula ukushintsha ukukhiqizwa.

Izindleko zokukhiqiza eziphansi: ukusebenza kahle kokukhiqizwa kokufa okuqhubekayo kuphezulu, inani lemishini yokunyathelisa lincane, inani labasebenza opharetha nendawo yokusebenzela incane, okunciphisa ukugcinwa nokuthuthwa kwemikhiqizo eqediwe, ngakho-ke izindleko zokukhiqiza eziphelele ze izingxenye zomkhiqizo aziphezulu.

Impilo ende yesikhunta: ukwakheka okuyinkimbinkimbi kwangaphakathi nangaphandle kungahlukaniswa kwaba bobunjwa besilisa nabesifazane, okungasikwa igxathu negxathu. Inqubo yokusebenza ingahlakazeka eziteshini eziningana, futhi isikhala singasethwa endaweni lapho inqubo yokusebenza igxilwe khona, ukuze kugwenywe inkinga yobukhulu bodonga obuncane kakhulu besilisa nabesifazane abafayo, shintsha isimo sokucindezeleka kowesilisa futhi owesifazane uyafa, futhi athuthukise amandla okufa. Ngaphezu kwalokho, i-die eqhubekayo futhi isebenzisa ipuleti lokukhipha njenge-punch guide plate, enenzuzo enkulu yokwenza ngcono impilo yokufa.

D. Izindleko zokukhiqiza eziphezulu zesikhunta: i-die progressive inezindleko eziphezulu zokukhiqiza ngenxa yesakhiwo sayo esiyinkimbinkimbi, ukunemba okuphezulu kokukhiqiza, umjikelezo omude nokusetshenziswa kwempahla ephansi. Isicelo: kufanelekile ukukhiqizwa ngobuningi besayizi encane naphakathi ngesakhiwo esiyinkimbinkimbi.

Ukufa okuqhubekayo

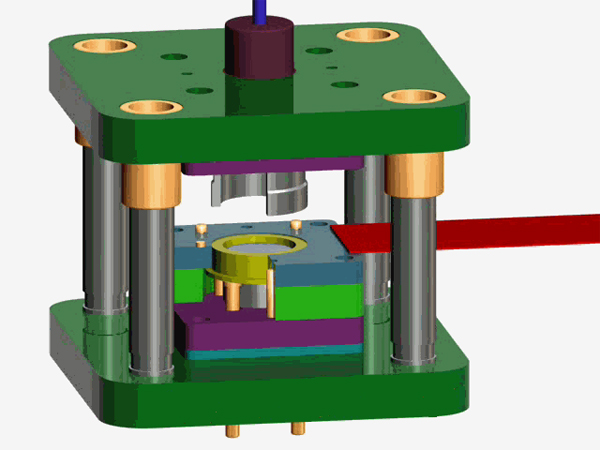

(4) Dlulisa nginyathela isikhunta (multi isikhundla ukudluliswa isikhunta):

ihlanganisa izici zenqubo eyodwa yokushaya isikhunta kanye nesikhunta sokuqhubekela phambili. Ngokusebenzisa uhlelo lokudlulisa ama-manipulator, lingabona ukudluliswa okusheshayo kwemikhiqizo kusikhunta. Kungathuthukisa kakhulu ukusebenza kahle kwemikhiqizo, kunciphise izindleko zokukhiqiza zemikhiqizo, konga izindleko zezinto ezibonakalayo, futhi ikhwalithi izinzile futhi inokwethenjelwa. Kufaka phakathi izici ezilandelayo:

A. Sebenzisa emshinini we-punch umshini weziteshi eziningi.

B. Isiteshi ngasinye yisikhunta esiphelele sobunjiniyela, siqedela inqubo ethile, ebizwa nge-sub mold. Kukhona ubudlelwane obuthile phakathi kwesikhunta esincane. Isikhunta ngasinye singalungiswa ngokuzimela ngaphandle kokuthinta isikhunta sangaphambili nangemuva.

C. Ukudluliswa kwezingxenye eziphakathi kwesikhunta kutholwa yi-manipulator. Isikhundla sokudluliswa kwezikhundla eziningi sikulungele ukukhiqizwa okuzenzakalelayo nokuphathwa okuhlakaniphile kwekhompyutha nokuphathwa. Isetshenziselwa ukukhiqizwa kwezingxenye ngokunemba okuphezulu, ikhwalithi ephezulu kanye nesakhiwo esiyinkimbinkimbi.

Ukusetshenziswa kwesikhunta noma ukufa:

(1). Imikhiqizo ye-elekthronikhi neyokuxhumana;

(2). Imishini yehhovisi;

(3). Izingxenye ezisele zemoto;

(4). Imishini yasendlini;

(5) Imishini kagesi;

(6). Ukuvikelwa kwezokwelapha nezemvelo;

(7). Izikhungo zezimboni;

(8) .Ukuhlakanipha okungelona iqiniso;

(9). Ezokuthutha;

(10). Izinto zokwakha, ikhishi nezinto zangasese namathuluzi;