Izingxenye ngomshini

Incazelo emfushane:

Izingxenye ngomshiniakha izingxenye eziyisisekelo zamadivayisi nemishini ehlukahlukene. Imishini nenqubo esetshenziswe yiyo ihlanganisa izinga eliphakeme kakhulu lokuklanywa komshini wamanje, izinto zokwakha, ukuncibilikisa, imishini, i-elekthronikhi, ukulawula izimboni neminye imikhakha.

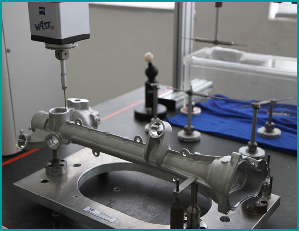

Ngokuthuthukiswa kobuchwepheshe, izingxenye ezinemba ngokunemba kanye nemishini kudlala indima ebaluleke kakhulu ekukhiqizeni izimboni zesimanje. IMESTECH ibihlinzeka amakhasimende ngokucubungula okunembile kwezingxenye zensimbi nezingezona zensimbi iminyaka.

Liyini iqhaza lezingxenye zensimbi ezisebenza kahle embonini yanamuhla?

Ithuluzi lomshini yi- "Umshini womama wezimboni” . Cishe konke ukukhiqizwa kwemishini yemishini akunakwehlukaniswa nokucutshungulwa kwemishini. Ngokuthuthuka okuqhubekayo kobuchwepheshe nemishini, kunesidingo esikhulu sezingxenye ezinemba kahle, ezinjengezindiza, i-aerospace, imoto, ezokwelapha, ubuhlakani bokufakelwa nokukhiqizwa kwe-chip, konke okungenakuhlukaniswa nokuxhaswa kwezingxenye ezinemba kahle. Ungayifeza kanjani ukusebenza kahle okuphezulu kanye nezindleko eziphansi zezingxenye zokunemba kuyindaba yomkhakha wokukhiqiza imishini.

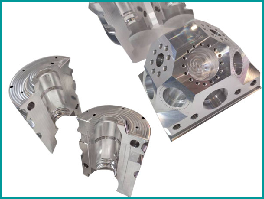

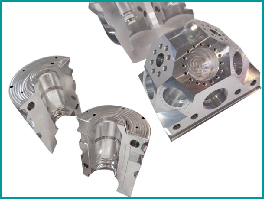

Isisekelo sensimbi

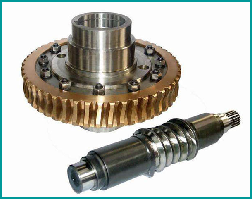

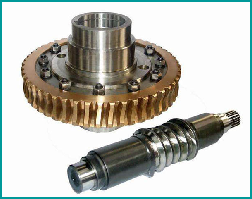

Igiya lesibungu

Izingxenye ngokunemba High

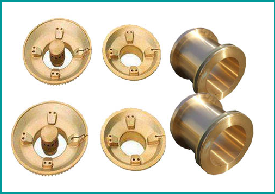

Izingxenye zethusi

Zingaki izinhlobo zenqubo machining owaziyo?

Precision machining inqubo yokushintsha usayizi noma ukusebenza kokwenza umsebenzi ngomshini wokucubungula. Ngokuya ngesimo sokushisa se-workpiece esetshenziswayo, ingahlukaniswa ngokucubungula okubandayo, ukucubungula okushisayo nokucubungula okukhethekile. Ngokuvamile kusetshenzwa ekamelweni lokushisa futhi akubangeli izinguquko zamakhemikhali noma zomzimba wendlela yokusebenza. Kubizwa ngokuthi ukucubungula okubandayo. Ngokuvamile, ukucubungula ngaphansi noma ngaphansi kwezinga lokushisa elijwayelekile kuzodala ushintsho lwamakhemikhali noma lomzimba womsebenzi, obizwa ngokuthi yi-thermal processing. Ukucubungula okubandayo kungahlukaniswa ukusika nokucindezela ukucubungula ngokuya ngokwehluka kwezindlela zokucubungula. Ukwelashwa ngokushisa, UKWAKHA, ukusakaza nokushisela kuvamile ekusebenzeni okushisayo. Precision ahlabayo ngokuvamile kokugcina ukucutshungulwa isixhumanisi ukuqinisekisa ukunemba izingxenye, futhi kubuye isixhumanisi umthwalo omningi kunayo yonke, ukwenza ezingaphezu kuka-60% we ukucutshungulwa izingxenye mechanical.

Kuyini ukusika ngomshini ngokunemba?

Ukusika ngomshini kuyindlela eyinhloko yokucubungula ngomshini, kubhekiswa kunqubo yokususa izinto ngokusebenzisa imishini eqondile.

Precision ahlabayo mechanical uhlobo ukucutshungulwa umshini ngobuciko eliphezulu. Kunezindlela ezimbili eziyinhloko zokubona ukucubungula ngokunemba kwezingxenye:

(1) Enye ukusebenzisa amathuluzi omshini wokunemba okuphezulu ukucubungula izingxenye zokunemba okuphezulu, njengokuxhumanisa umshini oyisidina, umshini wokugaya intambo, umshini wokugaya izikelemu, umshini wokugaya, i-optical grinder, ukucacisa okuphezulu kwangaphandle, i-high-precision hob grinder, ephezulu I-lathe yentambo -precision, njll. Lawa mathuluzi omshini angamathuluzi akhethekile wokucacisa, asetshenziselwa ukucubungula uhlobo oluthile lwezingxenye, njengamagiya, ama-turbines, isikulufa, amathuluzi wokusika, shaft yokudlulisa ephezulu kanye nebhokisi lenjini, njll. La mathuluzi emishini asebenza kahle kakhulu futhi anembile ngokucubungula inhloso ekhethekile.

(2) Okwesibili ukusebenzisa ubuchwepheshe besinxephezelo sephutha ukuthuthukisa ukucubungula kokunemba kwezingxenye. Amathuluzi womshini wokulawula wokuchazwa ayinhloko umshini wokugaya we-CNC, umshini wokugaya i-CNC, i-CNC grinder, umshini we-CNC oyisicefe nowokugaya, kanye nesikhungo semishini esihlanganisiwe.

Amathuluzi womshini we-CNC ngokuvamile amathuluzi womshini wenhloso jikelele, ngenxa yokusetshenziswa kobuchwepheshe bohlelo lwekhompiyutha, angahlelwa ngaphambilini ekusetshenzisweni nasekulingisweni kwamakhompiyutha, anokuhambisana okuhle nokuzivumelanisa nezimo, okulungele ukwakheka okuyinkimbinkimbi, ukuhlukahluka kwezingxenye zokucubungula. Amathuluzi womshini we-CNC ayabiza, kepha angabona ukuzenzakalela kokucubungula, futhi abe nokunemba okuhle kokuphindaphindwa kokusebenza nokusebenza kahle kokukhiqiza.

Ungayikhetha kanjani imishini yokucubungula efanelekile?

Ngokuthuthukiswa kobuchwepheshe bokulawulwa kwamakhompiyutha, amathuluzi omshini amaningi ayahlanganiswa nohlelo lwe-CNC, ukuze kubonwe ukuzenzekelayo kokucubungula, gwema amaphutha wokusebenza ngesandla, futhi uthuthukise ukunemba kokusebenza nokuzinza. Ngakho-ke, amathuluzi womshini we-CNC asetshenziswa kabanzi emkhakheni wokukhiqiza izingxenye ngokunemba.

(1) CNC ukucutshungulwa ngokunemba kwe-shaft yensimbi enhle kuphezulu, ngekhwalithi yokucubungula ezinzile;

(2) Ingafeza ukuxhumana okuxhumanisa okuningi futhi icubungule izingxenye ezinomumo ongafanele.

(3) Lapho izingxenye ze-CNC zekhompiyutha enhle ziguqulwa, uhlelo lwe-NC kuphela oludinga ukuguqulwa ukonga isikhathi sokulungiselela ukukhiqiza.

(4) Ithuluzi lomshini ngokwawo linokunemba okuphezulu nokuqina, futhi lingakhetha inani lokucubungula elinenzuzo, futhi izinga lokukhipha liphakeme (ngokuvamile izikhathi ezi-3 kuye kwezi-5 zalokho kwethuluzi lomshini jikelele).

(5) Amathuluzi omshini azenzakalelayo kakhulu futhi anganciphisa ukuqina kwabasebenzi.

Ukucubungula okuhle kwe-CNC kusetshenziswa amathuluzi wokusika amafushane kuyisici esiyinhloko sezingxenye ze-hardware ezinhle. Abasiki abafushane banganciphisa kakhulu ukuphambuka kwamathuluzi, bese bezuza ikhwalithi ephezulu yendawo, bagweme ukuphinda basebenze, banciphise ukusetshenziswa kwezinduku zokushisela, futhi banciphise isikhathi sokucubungula se-EDM. Lapho ucabangela imishini emihlanu ye-axis, kuyadingeka ukuthi ucabangele umgomo wokusebenzisa i-die-axis processing die: ukuqedela ukucubungula konke kokusebenza ngento emfushane yokusika ngangokunokwenzeka, kepha futhi ukunciphisa uhlelo, ukubamba nokucubungula isikhathi ukuthola ikhwalithi ephezulu ephelele yomhlaba.

Ungayenza kanjani inqubo yokucubungula enengqondo?

(1) Isigaba sokucubungula esibi. Ukusika iningi lesabelo sokucubungula kwendawo ngayinye yokucubungula nokukhiqiza ibhentshimakhi eqondile, okubaluleke kakhulu ukucubungula ukukhiqiza ngangokunokwenzeka.

(2) Isigaba sokuqeda. Susa ukushiyeka okungenzeka ngemuva kokucutshungulwa okunzima, lungiselela ukuqeda ukubukeka, kudinga ukufinyelela ukunemba okudingekayo kokulungiswa, uqinisekise isibonelelo esifanele sokuqeda, bese uqedela ukucubungula okungaphezulu kwesibili ndawonye.

(3) Isigaba sokuqeda. Kulesi sigaba, kukhethwa isivinini esikhulu sokusika, okuphakelayo okuncane nokujula kokusika ukuze kususwe isabelo sokuqeda esisele ngenqubo yangaphambilini ukuze ukubukeka kwezingxenye kuhlangabezane nezidingo zobuchwepheshe bemidwebo.

(4) Ultrafine machining isigaba. Isetshenziselwa ukunciphisa inani lobukhulu bendawo noma ukuqinisa ukubukeka kokucubungula. Isetshenziselwa ukucubungula indawo ngezidingo eziphakeme zokuqina kwendawo (ra <0.32 um).

(5) Ultra-emihle ukucutshungulwa isigaba. Ukunemba kwemishini kungu-0.1-0.01 micron kanye nenani le-roughness value RA ingaphansi kuka-micron engu-0.001. Izindlela zokucubungula eziyinhloko yilezi: ukusika okuhle, ukugaya isibuko, ukugaya okuhle nokupholisha.

Ungayikhetha kanjani impahla efanelekayo yomsebenzi?

Ukucubungula okuqondile, hhayi zonke izinto zokusetshenziswa ezingafiswa ukwenza ukucubungula okunemba, ezinye izinto zokusetshenziswa zinzima kakhulu, zeqa ubulukhuni bezingxenye zomshini wokucubungula, zingawa izingxenye zomshini, ngakho-ke lezi zinto zokusetshenziswa azifanele ukucubungula kahle kwemishini, ngaphandle kokuthi yenziwe ngezinto zokusetshenziswa ezihlukile, noma ukusika kwe-laser.

Izinto zokusetshenziswa ngokunemba machining zingahlukaniswa ngezigaba ezimbili, izinto zokusetshenziswa zensimbi nezinto zokusetshenziswa ezingezona ezensimbi.

Ngokuqondene nezinto zokusetshenziswa zensimbi, ukuqina kwensimbi yokugqwala kuphakeme, kulandelwa insimbi yensimbi, kulandele ithusi ne-aluminium ethambile.

Ukucubungula izinto zobumba nezamapulasitiki kungokwokucubungula izinto zokusetshenziswa ezingezona zensimbi.

1. Okokuqala, izingxenye kufanele zibe nezinga elithile lobulukhuni. Kwezinye izinhlelo zokusebenza, ukuphakama kobunzima bezinto ezingenalutho, kungcono. Kukhawulelwe kuphela kuzidingo zobulukhuni bezingxenye ezenziwe ngomshini. Izinto ezenziwe ngomshini azikwazi ukuba nzima kakhulu. Uma zilukhuni kunezingxenye ezenziwe ngomshini, azikwazi ukwenziwa ngomshini.

2. Okwesibili, okokusebenza kusezingeni eliphakathi nobulukhuni nobumnene. Okungenani izinga elilodwa lobulukhuni liphansi kunalelo lezingxenye zomshini. Ngasikhathi sinye, kuya ngomsebenzi wamadivayisi acutshungulwayo kanye nokukhethwa okulungile kwezinto zokwakha izingxenye zomshini.

Ngamafuphi, kusekhona ezinye izidingo zekhwalithi yezinto ezibonakalayo ekusebenzeni kahle, hhayi zonke izinto ezilungele ukucutshungulwa, njengezinto ezithambile noma ezilukhuni, okwedlule akudingeki ukuthi kusetshenzwe, kanti okwamuva akukwazi ukukucubungula.

IMestech inikezela amakhasimende ngokukhiqiza nokucubungula izingxenye zensimbi ezinemba. Uma udinga eminye imininingwane, sicela uxhumane nathi.