Ukucubungula kwensimbi (ukwenziwa kwensimbi), luhlobo lokucubungula ubuchwepheshe kanye nemisebenzi yokukhiqiza yokwenza ama-athikili, izingxenye kanye nezinto ezisuka ezintweni zensimbi.

Izingxenye zensimbi zisetshenziswa kabanzi emishinini nasemishini ehlukahlukene. Izingxenye zensimbi zinokuqina kobukhulu, amandla nobulukhuni, izici zokumelana nokushisa okuphezulu kanye nokuphansi, okuvame ukusetshenziselwa ukwenza izingxenye zokunemba. Uma kuqhathaniswa nezingxenye zepulasitiki, kunezinhlobo eziningi zezinto zokwenziwa kwezingxenye zensimbi, njenge-aluminium alloy, i-alloy yethusi, i-zinc alloy, insimbi, i-titanium alloy, i-magnesium alloy, njll, enezakhiwo ezahlukahlukene. Phakathi kwazo, i-ferroalloy, i-aluminium alloy, i-alloy yethusi ne-zinc alloy zisetshenziswa kakhulu emikhiqizweni yezimboni neyomphakathi. Lezi zinto zensimbi zinezinto ezahlukahlukene zomzimba nezamakhemikhali, ukwakheka okuhlukile nokuma kwezingxenye zensimbi zokucubungula ubuchwepheshe kunomehluko omkhulu.

Izindlela zokucubungula eziyinhloko zezingxenye zensimbi yilezi: machining, stamping, precision casting, powder metallurgy, metal injection injection.

Machining inqubo yokushintsha ubukhulu jikelele noma ukusebenza workpiece ngokusebenzisa uhlobo imishini mechanical. Ngokwokwahluka kwezindlela zokucubungula, kungahlukaniswa kube ukusika nokucindezela imishini. Stamping uhlobo lwendlela yokucubungula esebenzisa ukucindezela nokufa ukukhipha amandla wangaphandle eshidini, umucu, ipayipi nephrofayili ukukhiqiza ukusikeka kwepulasitiki noma ukwahlukana, ukuze kutholakale ukwakheka nobukhulu obudingekayo bento yokusebenza (ingxenye enginyathela).

Precision thusi, powder yokusansimbi futhi umjovo metal udini basonta inqubo ezishisayo ukusebenza. Zakhiwa emgodini wesikhunta ngokushisa insimbi encibilikisiwe ekushiseni okuphezulu ukuthola isimo nosayizi odingekayo. Kukhona futhi imishini ekhethekile, njenge: laser machining, i-EDM, imishini ye-ultrasonic, i-electrochemical machining, i-particle beam machining kanye ne-ultra-high speed machining. Ukuguqula, ukugaya, ukwakha, ukusakaza, ukugaya, i-CNC machining, i-CNC machining. Zonke zingezomshini.

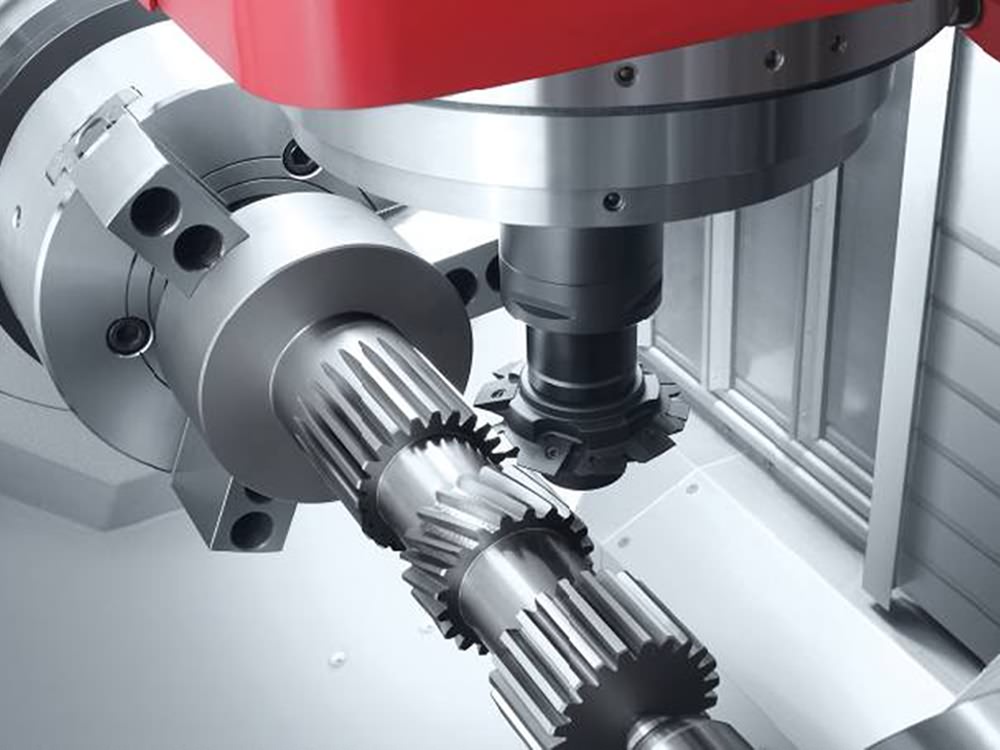

Amathuluzi womshini wokucubungula izinsimbi

Amathuluzi womshini wokucubungula izinsimbi

Shaft machining - isikhungo lathe

Imishini yokukhipha kagesi -EDM

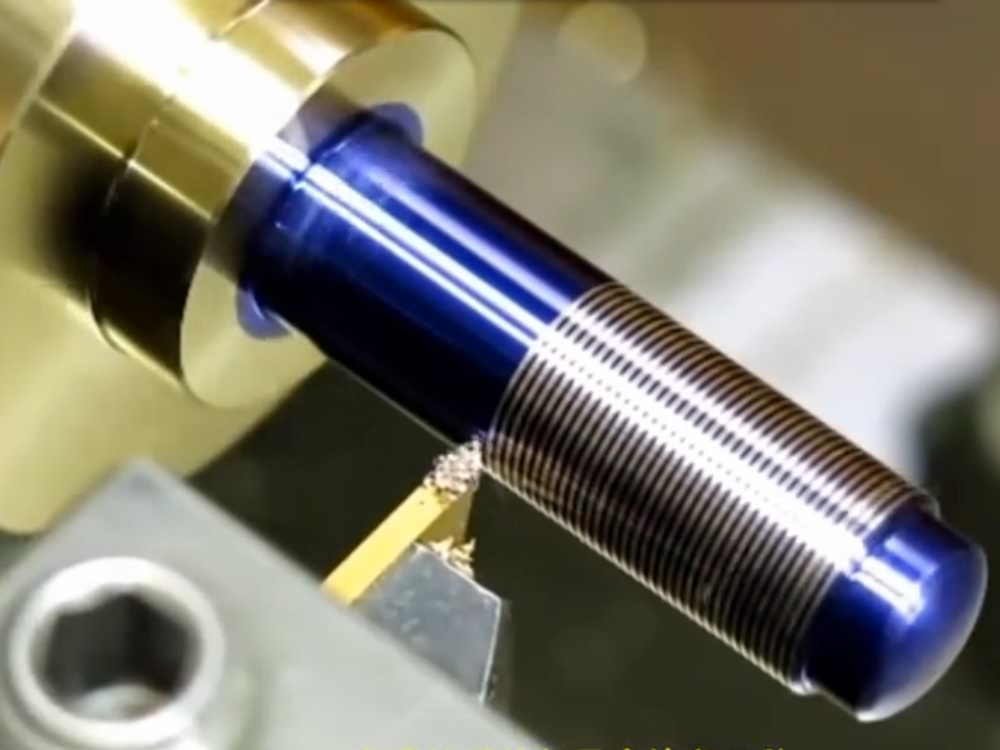

Precision isikulufa machining

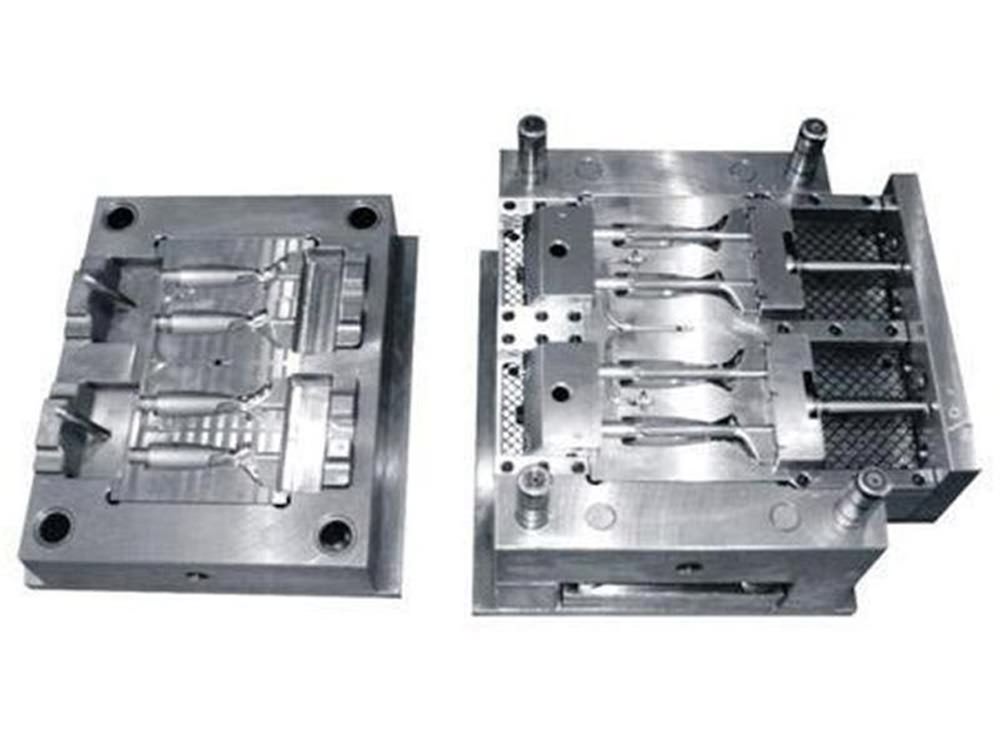

Die umshini ekubunjweni

Die ekubunjweni die

Umshini isibhakela

Wokushaya die

Ukuboniswa kwezingxenye zensimbi:

1. Izinsimbi zensimbi eziyizinsimbi: izingxenye ezenziwe nge-iron, i-chromium, i-manganese nezinto zazo ze-alloy.

Precision isikhunta izingxenye

CNC ngomshini izingxenye zensimbi

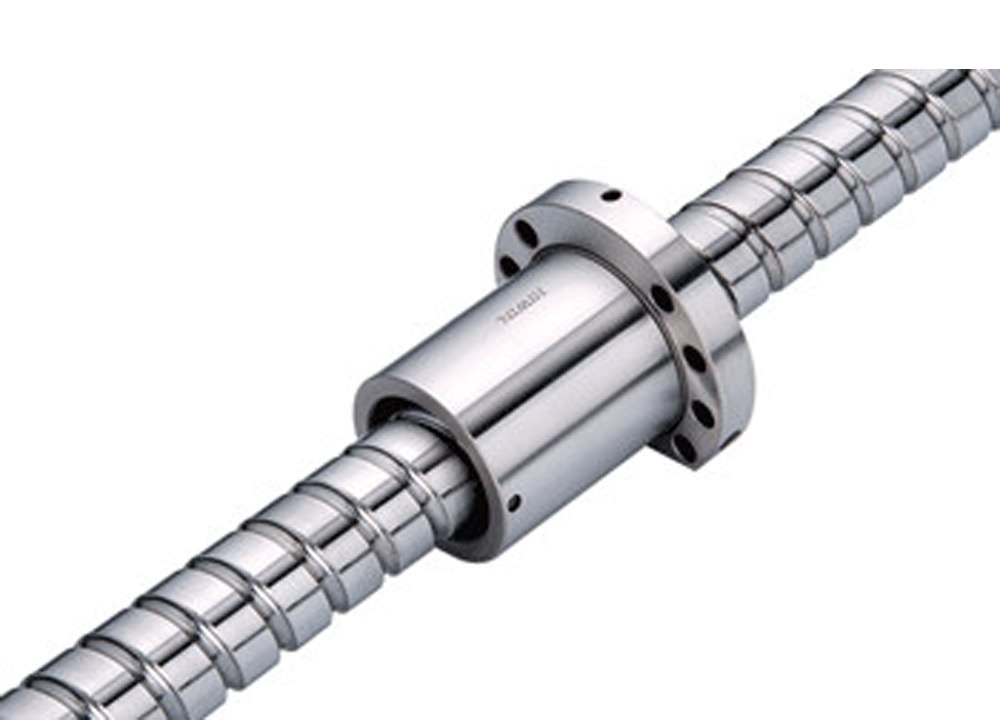

Precision lead isikulufa

Izingxenye zokudlulisela zeGiya

2.Izingxenye zensimbi ezingafakwanga: ama-alloys avamile angafaki i-aluminium alloy, i-alloy yethusi, i-magnesium alloy, i-nickel alloy, i-tin alloy, i-tantalum alloy, i-titanium alloy, i-zinc alloy, i-molybdenum alloy, i-zirconium alloy, njll.

Amagiya ethusi

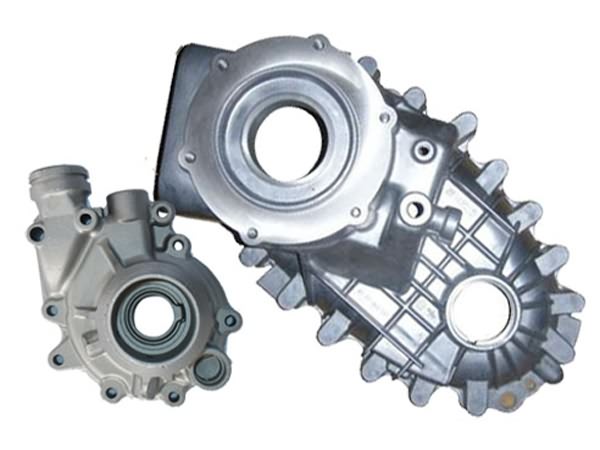

IZinc ifa ikhipha izindlu

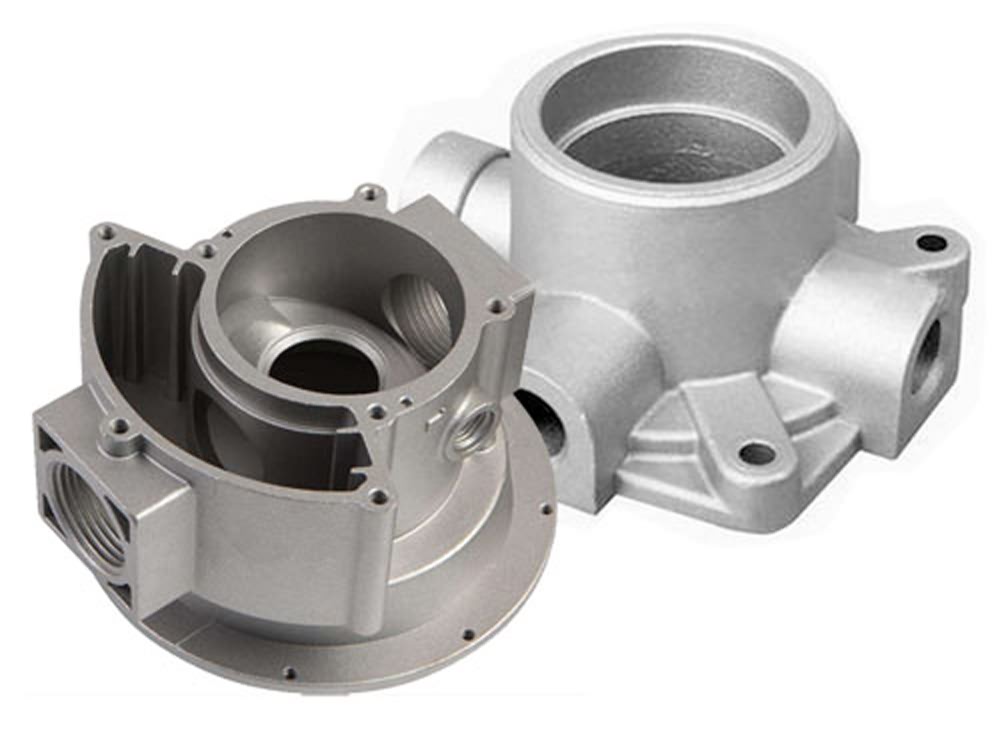

Isembozo sokugaya i-Aluminium

Izindlu ze-Aluminium die cast

Ukwelashwa ngaphezulu kungahlukaniswa ngezici ezine

1.Umshini wokwelashwa komhlaba: sandblasting, ukuqhuma kwesibhamu, ukupholisha, ukugingqa, ukupholisha, ukuxubha, ukufafaza, ukudweba, ukufaka uwoyela, njll.

2. Ukwelashwa kwendawo ngamakhemikhali: i-bluing kanye ne-blackening, i-phosphating, i-pickling, i-plating engenazinsimbi yezinsimbi nama-alloys ahlukahlukene, ukwelashwa kwe-TD, ukwelashwa kwe-QPQ, i-chemical oxidation, njll.

3.Ukwelashwa okuphezulu komhlaba: i-anodic oxidation, ukupholisha i-electrochemical, i-electroplating, njll.

Ukwelashwa kwendawo yesimanje: ukwakheka kwe-vapor yamakhemikhali i-CVD, i-PVD yokufaka umhwamuko ngokomzimba, ukufakwa kwe-ion, i-ion plating, ukwelashwa kwendawo yensimbi, njll.

IMestech inikezela ngamakhasimende ngezinsizakalo zokwakha nezokukhiqiza zezingxenye zensimbi kufaka phakathi insimbi, i-aluminium alloy, i-zinc alloy, i-alloy yethusi ne-titanium alloy. Sicela uxhumane nathi uma kunesidingo.