Ukuhlobisa okungaphakathi kwesikhunta-IML

Incazelo emfushane:

I-In-Mold Decoration (esiyibize nge-IMD) ubuchwepheshe obudumile bokuhlobisa umhlaba emhlabeni. Kusetshenziswa ikakhulukazi ekuhlobiseni komhlaba nakwiphaneli elisebenzayo lemishini kagesi yasendlini. Imvamisa isetshenziswa kuphaneli nesibonakaliso selensi yefoni yeselula negobolondo, iphaneli yokulawula umshini wokuwasha, iphaneli yokulawula isiqandisi, iphaneli yokulawula umoya, ideshibhodi yezimoto, iphaneli yokulawula irayisi yokupheka njalonjalo.

I-IMD ihlukaniswe nge-IML (IMF ngeka-IML) ne-IMR, umehluko omkhulu phakathi kwalezi zinqubo ezimbili ukuthi ngabe umkhiqizo womkhiqizo unefilimu evikelayo esobala.

I-IMD ifaka phakathi i-IML, IMF, IMR

I-IML: IN MOLDING LABEL (izinto zokuphrinta nezingxenye zepulasitiki)

I-IMF: IN MOLDING FILM (efanayo ne-IML)

I-IMR: IN MOLD READ

I-IML (IN MOLD LABEL): Izici eziphawuleka kakhulu zenqubo ye-IML yilezi: indawo ungqimba lwefilimu esobala eqinisiwe, maphakathi ungqimba lwephethini lokuphrinta, ngemuva ungqimba lweplastiki, ngoba uyinki ubambeke phakathi, ukuvimbela ebusweni kusuka ukunwaya futhi nemihuzuko, futhi ungagcina iphethini umbala elikhanyayo hhayi fade isikhathi eside. Lezi zici zenza imikhiqizo ye-IML isetshenziswe kabanzi.

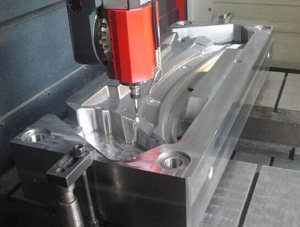

Inqubo ye-IML: Ukuphrinta ifilimu kwe-PET- ukuphrinta indiza - ukomisa inki okungaguquki - Namathisela ifilimu evikelayo - isibhakela imbobo -I-Thermoforming - ukucheba umngcele wendlela - udini lomjovo wezinto ezibonakalayo.

Isakhiwo sesigaba ezintathu somkhiqizo we-IML:

1.Ubuso: Ifilimu (ifilimu ye-PET, ukuphrinta noma iyiphi iphethini nombala). Izinkuni, i-cortex, uqalo, indwangu, izinkuni zokulingisa, isikhumba sokulingisa, indwangu yokulingisa, insimbi yokulingisa njalonjalo;

2, ungqimba oluphakathi: uyinki (Ink), iglu, njll.

3, ngezansi: ipulasitiki (ABS / PC / TPU / PP / PVC, njll.).

I-IMR (IN MOLD ROLLER): Kule nqubo, iphethini liphrintiwe kwifilimu, futhi ifilimu nomgodi wesikhunta kuhlanganiswa ngumphakeli wefilimu wokubumba umjovo.

Ngemuva kokujova, ungqimba lukayinki onephethini wehlukaniswa nefilimu, futhi ungqimba lukayinki lusele engxenyeni yepulasitiki ukuthola ingxenye yepulasitiki ngephethini yokuhlobisa.

Ayikho ifilimu evikelayo ebonakalayo endaweni yokugcina yomkhiqizo, futhi ifilimu ikhiqizwa kuphela. Isithwali kule nqubo. Kepha inzuzo ye-IMR ilele ezingeni eliphakeme le-automation ekukhiqizeni kanye nezindleko eziphansi zokukhiqiza ngobuningi. Izithiyo ze-IMR: Isendlalelo sephethini ephrintiwe ebusweni bomkhiqizo, ubukhulu bama-microns ambalwa kuphela, umkhiqizo uzoba lula ukugqobhoza ungqimba lwephethini ephrintiwe ngemuva kwesikhathi, kepha futhi kulula ukufiphala, okuholela ekungabukekeni ubuso. Ngaphezu kwalokho, umjikelezo omusha wokuthuthukiswa komkhiqizo mude, izindleko zokuthuthuka ziphakeme, umbala wephethini awukwazi ukufeza ushintsho oluncane lwe-batch futhi inqubo ye-IMR ayikwazi ukunqoba ubuthakathaka.Kuyadingeka ukuchaza ngomqondo: Izeluleko ezibalulekile ze-IMR ungqimba wokukhishwa.

Inqubo ye-IMR: I-PET Film - i-ejenti yokukhipha - uyinki wokuphrinta - Ukuphrinta isibopho - umjovo wangaphakathi wepulasitiki - uyinki noplastiki bese - ngemuva kokuvula isikhunta, ifilimu izokhipha ngokuzenzakalela kuyinki. Ngaphandle kwekhwalithi yamashidi aprintiwe, uthuli lunomthelela omkhulu kwikhwalithi yabo, futhi umkhiqizo wabo kufanele wenziwe endaweni ehlanzekile engenalo uthuli

Umehluko oyisisekelo phakathi kwe-IML ne-IMR ukuthi kunezindawo ezahlukahlukene zamalensi, ezinamashidi e-PET noma e-PC ebusweni be-IML kanye no-inki kuphela ku-IMR surface. Ukumelana nokugqoka kwe-IML, ukumelana kokuqala kanye nephethini yombala isikhathi eside. I-IMR ilungele ukukhiqizwa ngobuningi nezindleko eziphansi. I-IMR ayivimbeli kakhulu ukugqoka, izingcingo zakwaNokia neMoto ziyingxenye yobuchwepheshe be-IMR, isikhathi esithe ukuqina futhi sizodala imihuzuko; ukubuyela emuva okukhulu kwe-IML ukuthi ayinakusetshenziswa njengobuchwepheshe bonke be-IML, kukhawulwe kuphela endaweni eqhubekayo.

Izici zemikhiqizo ye-IMD / IML:

1, ukwakheka komkhiqizo nokucaca kombala, akusoze kwaphela, nomqondo wobukhulu obuthathu;

2, umkhiqizo unempilo ende yokusebenza, ukumelana nokugqokwa komhlaba kanye nokumelana kokuqala, futhi kugcina ukubukeka kuhlanzekile futhi kuhlanzekile.

3, ukunemba kokuphrinta kuka + 0.05mm, kungaphrinta amaphethini anzima futhi anemibala eminingi;

4, iphethini nombala kungashintshwa nganoma yisiphi isikhathi ngesikhathi senqubo yokukhiqiza ngaphandle kokushintsha isikhunta.

5. Ukuma kwemikhiqizo ye-IML akugcini ngokuma kwendiza kuphela, kodwa futhi nokuma kobuso obugobile, indawo egobile, indawo ethambekele neminye imiphumela yokubukeka ekhethekile.

I-6, umkhiqizo awuqukethe okunamathiselwe okusekelwe kuphela, okuhlangabezana nezidingo zemvelo.

7. Ukudluliswa kwamawindi kufinyelela kuma-92%.

8. Okhiye abasebenzayo banamabhamu afanayo nesibambo esihle. Izinkinobho zi-convex lapho zifakwa esikhunjeni. Impilo yokhiye ingafinyelela izikhathi ezingaphezu kwesigidi esisodwa.

Ikesi le-IMD lepulasitiki

Iphaneli engabonakali ene-IML

Icala le-IML ledivayisi yokuxhumana

Iphaneli yokhiye we-IMD yasekhaya

Uhlelo lokusebenza lwe-IML

Njengamanje, i-IML isetshenziswa kabanzi emikhakheni eminingi, njengamawindi, amagobolondo, amalensi, iphaneli yokulawula imishini yezimoto neyasendlini kanye nezingxenye zokuhlobisa, ezizothuthukiswa zibe amalebula aphikisana nomgunyathi nemboni yezimoto ngokuzayo. Umkhiqizo unokusebenza okuhle kwe-sunscreen, ungasetshenziselwa izimpawu zemoto, ubulukhuni obufinyelela ku-2H ~ 3H, ungasetshenziselwa amalensi omakhalekhukhwini, njll., Impilo yenkinobho ingafinyelela izikhathi ezingaphezu kwesigidi esingu-1, ingasetshenziselwa abapheki belayisi ngakho-ke vula.

I-IMD / IML ingaveza ingxenye enokubukeka okuhle futhi igqoke indawo engazweli. Kepha izindleko ziphakeme kunezingxenye zomhlaba ezijwayelekile. Uma umkhiqizo wakho udinga umkhiqizo onjalo, sicela uxhumane nathi.