Die isikhunta ekubunjweni

Incazelo emfushane:

Die isikhunta ekubunjweniuhlobo imishini yensimbi die ekubunjweni. Isikhunta sokufa siqukethe isikhunta "ikhava yokufa isigamu" kanti esinye "isigamu sokufa isigamu.

Izikhunta ze-Die-casting zisetshenziselwa ukwakha izingxenye zensimbi ezingezona ezinesakhiwo esiyinkimbinkimbi nokuma. Njengokukhiqizwa ngobuningi kwe-aluminium alloy, i-zinc alloy, izingxenye ze-magnesium kanye ne-alloy izingxenye, ezisetshenziswa kakhulu ezimotweni, ku-elekthronikhi, kugesi, kufenisha, kwezokwelapha neminye imikhiqizo.

Kuyini die ekubunjweni isikhunta

Die thusi igama elifushane ingcindezi thusi. Kuyindlela yokugcwalisa umgodi wokufa ekubunjweni kwesikhunta ngensimbi engamanzi noma engamanzi ngaphansi kwengcindezi ephezulu

ngesivinini esikhulu futhi uqinise ngokushesha ukuthola ukusakaza. Isikhunta esisetshenzisiwe sibizwa ngokuthi yi-die casting die mold.

Izinhlobo zokufa ekubunjweni kwesikhunta

Ngokusho kokusetshenziswa, ingahlukaniswa izingxenye zesakhiwo nezingxenye zokuhlobisa.

Ngokuya ngesimo sesicelo, ingahlukaniswa ibe yisikhunta semoto, i-3C yomkhiqizo ifa isikhunta, ithoyizi lokufa isikhunta, njll.

Ngokuya ngezici zokuma nodonga ukujiya, ingabuye ihlukaniswe ibe yisikhunta esincanyana esinezinsimbi zokufa, ibhokisi lokufa lokuphonsa kanye ne-disc die-casting mold

Umshini wokuphonsa umshini wokufa, u-die-casting alloy kanye ne-die-casting die yizinto ezintathu zokukhiqizwa kokufa, okunye okusemqoka.

Uhlobo lomshini wokuphonsa, ufe imingcele yokwakhiwa, inqubo yokufa nokuhlelwa kwefektri kuncike entweni yokuphonsa i-die-casting alloy, ngakho-ke ukwahlukaniswa kokufa kukokufa ngokuya ngento ye-alloy kufaneleke kakhulu ekukhiqizeni. zingu-die-thusi isikhunta zingahlukaniswa nge-aluminium alloy die-casting mold, zinc alloy die-casting mold, magnesium alloy die-casting mold and copper alloy die-casting mold. Imininingwane imi kanje:

1) .Aluminium ufe ekubunjweni isikhunta

2) .Zinc die ekubunjweni isikhunta

3) .Magnesium ingxubevange die-ekubunjweni isikhunta

4) .Copper ingxubevange die-ekubunjweni isikhunta

5) .Sintering isikhunta

I-Aluminium die isakaza isikhunta

Zinc die ekubunjweni isikhunta

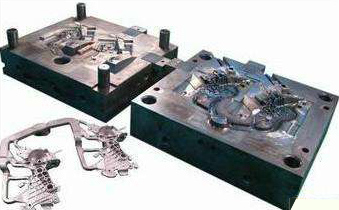

Die ekubunjweni isikhunta ukwakheka

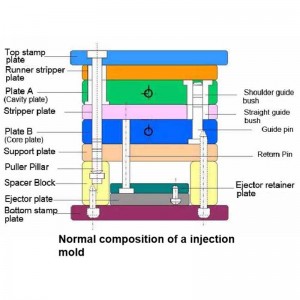

Ukwakheka isikhunta die ekubunjweni kungenziwa cishe ihlukaniswe yaba izingxenye ezimbili:

Umile isikhunta uhhafu:Ukulungiswa kupuleti elilinganiselwe lokufaka umshini wokuphonsa umshini wokufa, nge-sprue exhunywe ngombhobho noma igumbi lokucindezela;

Ezithathekayo isikhunta uhhafu:Ukuze kumiswe ku-plate obandayo bomshini wokufa, futhi kwahanjiswa nepuleti ekhuphukayo ukuvula nokuvala isikhunta. Lapho kuvalwa isikhunta, umgodi wesikhunta kanye nohlelo lokusakaza kuyadalwa, futhi insimbi ketshezi igcwalisa isikhunta isikhunta ngaphansi kwengcindezi ephezulu. Lapho uvula isikhunta, uhhafu wesikhunta osusekayo kanye nokuma okumile kwesikhunta kuyahlukaniswa, futhi ukuphonsa kukhishwa ngosizo lomshini wokukhipha osethwe kuhafu wesikhunta osusekayo.

Isakhiwo se-die-casting die sifaka ama-sub-system alandelayo ngokwemisebenzi yawo:

1) Cavity: ebusweni sprue (sprue sleeve); Okuyinhloko: isango langaphakathi lobuso bangaphakathi.

2) Izingxenye zomhlahlandlela: okuthunyelwe kokuqondisa; umkhono umkhono.

3) Qalisa indlela Push induku (thimble), induku yokusetha kabusha, ipuleti yokulungisa induku, ipuleti lokucindezela, iposi yokuqondisa ipuleti, iphusha umkhono wensimbi.

4) Side core edonsa indlela Boss, imbobo (ohlangothini), wedge block, umkhawulo entwasahlobo, isikulufa.

5) Ukuchichima kwesistimu yokuchichima komkhombe, umkhombe wokukhipha.

6) izingxenye Ukusekela.

Kumile isikhunta sesisekelo, ipuleti lesisekelo sesikhunta, ibhulokhi yesikhuni (ukuhlangana, ukubeka, umsebenzi wokufaka).

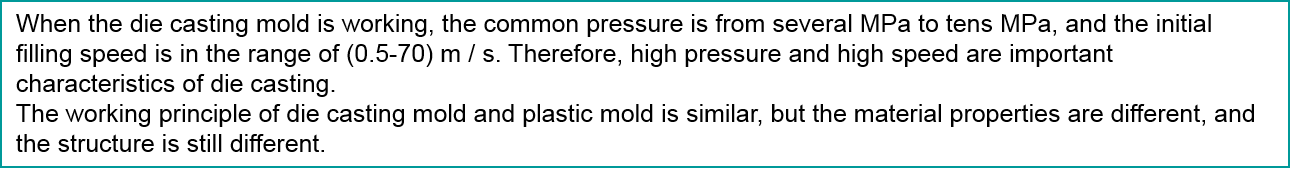

Umehluko phakathi die ekubunjweni isikhunta futhi isikhunta plastic:

1.Ingcindezi umjovo die die ekubunjweni die likhulu. Ngakho-ke, isifanekiso kufanele sibe sikhulu. Vimbela ukusonteka.

2. Isango lokufa ekubunjweni kwesikhunta lihlukile kuleso lesikhunta somjovo. Ingcindezi ephezulu yokugeleza kwezinto ezibonakalayo ezobola yisigaxa esihlukanisayo.

3. Umnyombo wokufa u-die casting awudingi ukuqina. Ngoba izinga lokushisa emgodini wokufa lingaphezu kuka-700 ℃. Ngakho-ke, ukubunjwa ngakunye kufana nokucisha okukodwa. Umgodi uzoba nzima ngokwengeziwe. Isikhunta somjovo ojwayelekile kufanele sicinywe sibe ngenhla kwe-hrc52.

4. Ngokuvamile, umgodi wokufa-wokulingisa die udinga ukwelashwa nitriding. Vimbela ingxubevange ekunamatheleni emgodini wesikhunta.

5. Ngokuvamile, ukugqwala die die ekubunjweni die kuyinto enkulu kuqhathaniswa. Ubuso bangaphandle ngokuvamile buhlaza okwesibhakabhaka.

6. kuqhathaniswa umjovo isikhunta. Ukuvunyelwa okulingana kwengxenye ehambayo yensimbi yokufa (njenge-slider edonsa isisekelo) kufanele ibe nkulu. Ngoba izinga lokushisa eliphezulu inqubo die ekubunjweni kuzobangela ukwanda ezishisayo. Uma imvume incane kakhulu, isikhunta sizonamathela.

7. Ingaphezulu lokuvalelisa die-ekubunjweni die ine izidingo ezifanayo ezifanayo. Ngenxa yokuthi uketshezi lwe-alloy lungcono kakhulu kunalolo lweplastiki, kuyingozi kakhulu ekushiseni okuphezulu nasekugelezeni kwengcindezi ephezulu ukuphuma endaweni yokuvaleka.

8. Isikhunta somjovo ngokuvamile sincike kuthimble. Indawo yokuvaleka ingavuleleka. Isikhunta sokufa kufanele sihlinzekwe ngesikhala sokukhipha kanye nesikhwama sokuqoqa i-slag (ukuqoqa ikhanda lezinto ezibandayo).

9. Ukwakhiwa akuhambelani. Ijubane lomjovo wokufa ekubunjweni kuyashesha. Ingcindezi yomjovo wesigaba sokuqala. Isikhunta sepulasitiki ngokuvamile sihlukaniswe umjovo amaningana, ingcindezi.

10. Isikhunta sokuphonsa sife isikhunta samapuleti amabili (angikaboni isikhunta sokuphonsa amapuleti amathathu okwamanje) ukuvulwa okukodwa. Izakhiwo zomkhiqizo ezahlukahlukene zesikhunta sepulasitiki zihlukile. 3 isikhunta ipuleti zivamile. Inombolo nokulandelana kokuvulwa kufaniswe nesakhiwo sokufa. I-thimble yesikwele ayijwayele ukusetshenziselwa isikhunta sokufa. Isilinda.

11. I-pin ethambekele (ukushisa okuphezulu nesisombululo esihle samanzi) kulula ukujamu, okuholela ekukhiqizeni isikhunta okungazinzile. Ngaphezu kwalokho, isikhunta seplastiki nesikhunta sokufa senziwe ngensimbi ehlukile; isikhunta sepulasitiki ngokuvamile sisebenzisa i-45 × yensimbi, i-T8, i-T10 nenye insimbi, kuyilapho kufakwa izinsimbi

Inkampani yakwaMestech igxile emkhakheni wokukhiqiza ngokunemba kanye nezingxenye zokukhiqiza iminyaka engaphezu kwengu-10, ngobuchwepheshe obuphambili bemboni kanye nesipiliyoni sokukhiqiza isikhunta esinothile. Imikhiqizo yenkampani ikakhulukazi imikhiqizo yepulasitiki noma izinto zegobolondo ezifana nemikhiqizo ye-elekthronikhi yedijithali, amadivayisi wezokwelapha, imikhiqizo yezinsana, njll. Le nkampani inekhono eliqinile lokwakheka kwesakhiwo nokuklanywa kwesikhunta, okunganikeza amakhasimende iziphakamiso ezenzelwe ukwakheka komkhiqizo kanye nezinhlelo ezinengqondo zesikhunta