Ibhokisi lokuhlangana kukagesi nokubumba

Incazelo emfushane:

Amabhokisi okuhlangana kagesizisetshenziselwa kabanzi ukudlulisa nokusabalalisa amandla nokuxhumana. Izingxenye eziyinhloko zegobolondo lebhokisi lokuhlangana nekhava ikakhulu zingamapulasitiki akhiqizwa umjovo wokubumba.

Amabhokisi okuhlangana kagesi asetshenziswa kakhulu ukudlulisa nokusabalalisa amandla nokuxhumana. Izingxenye eziyinhloko zegobolondo lebhokisi lokuhlangana nekhava ikakhulu zingamapulasitiki akhiqizwa umjovo wokubumba. Ibhokisi lokuhlangana lidinga ukuthobela izinga elijwayelekile lokusebenza kagesi, ngakho-ke sizokwethula ibhokisi lokuhlangana kagesi nokubumba lapha.

Liyini ibhokisi lokuhlangana kwepulasitiki?

Ibhokisi lokuhlangana kagesi libizwa nangokuthi ibhokisi lokuxhuma, ibhokisi lokugcina, isixhumi sikagesi, isisekelo sokugcina.

Ibhokisi lokuhlangana likagesi yindawo yokuxhumana kagesi evaliwe, ukuvikela ukuxhumana nokuhlinzeka ngesithiyo sokuphepha.

Ibhokisi elincane lensimbi noma lepulasitiki elihlanganayo lingaba yingxenye yomzila kagesi noma wiring cable (TPS) wiring cable (TPS) wiring system esakhiweni.

Uma idizayinelwe ukufakwa komhlaba, isetshenziswa kakhulu ophahleni, ngaphansi kwaphansi noma efihlwe ngemuva kwephaneli lokungena - ikakhulukazi ezindlini ezifuywayo noma ezentengiso. Uhlobo olufanele (njengalolo olukhonjiswe ngakwesobunxele) lungangcwatshwa kupulasitela wodonga (yize ukufihla okugcwele kungasavunyelwa ngamakhodi namazinga wanamuhla) noma kufakwe kukhonkolo - kukhombisa ikhava kuphela.

Amabhokisi kagesi asepulasitiki anama-plus nama-minus awo. Ngoba zingamapulasitiki, asikho isidingo sokunamathisela ucingo lwaphansi kuwo. Njengoba yenziwa ngento engeyona eyokuqhuba, amaswishi nezitolo azikwazi ukuphuma uma zithinta uhlangothi lwebhokisi.

Amabhokisi epulasitiki imvamisa eza nezimbobo zokuthayipha zokunamathiselwa kalula kokushintshwa nezitolo. Lawa mabhokisi eza ngeqembu elilodwa, iqembu lamaqembu amabili, kanye nokulungiswa kwamaqembu amaningi.

Izinhlobo zebhokisi lokuhlangana kagesi

Izinhlobo zamabhokisi okuhlangana kagesi ahlukahlukene: uhlobo lwasendlini, uhlobo lwangaphandle, uhlobo lokumelana namandla kagesi, nohlobo olungenamanzi. Izinsizakusebenza nezokuphepha ziyahlukahluka kusuka ezindaweni ezahlukene nasemazweni. Ngakho-ke isikhunta somjovo nokwenza ukucubungula nakho kuhlukile.

1. ibhokisi lokuhlangana elingaphakathi endlini.

Izinhlobo ze-Resin: ABS, PVC

Iningi lalawa angamabhokisi okuxhuma amahhovisi nasekhaya. Zisetshenziselwa ukusatshalaliswa kwamandla endlini kanye nokulawulwa okuphakathi, kanye nokunikezwa kwamandla okucishiwe, nokufinyelela kolayini nokuxhumana. Amandla okusebenza ajwayelekile angaphansi kwama-volts angama-250. I-resin yepulasitiki iyadingeka ukuthi ihambisane nebanga le-flame retardant UL94 V1 ~ V0.

2. ibhokisi lokuhlangana elingaphandle.

Izinhlobo ze-Resin: ABS, ABS / PC

Ibhokisi lokuhlangana langaphandle liyadingeka ukuze likwazi ukumelana nokushisa okuphezulu okuphansi naphansi kanye nomswakama wemvula nokugqwala kwelanga okuguga, ukwakheka komkhiqizo okungangeni manzi, ukuguga kwemisebe ye-anti-ultraviolet, ukuzivumelanisa nendawo yokushisa ephezulu naphansi. Kuyadingeka ukusebenzisa ama-plastiki asezingeni eliphakeme, njenge-PC noma inayiloni, enezithasiselo ezikhethekile ezinokumelana okuhle kwe-ultraviolet nokusebenza kokushisa okuphezulu nokuphansi.

3. Ibhokisi lokuhlangana lezimboni.

Izinhlobo ze-Resin: ABS, ABS / PC, Inayiloni

Ibhokisi lokuhlangana lezimboni, livame ukuba nezidingo zokusebenza ezikhethekile, njengokunemba okuthe ngce nokuqina, uwoyela ne-alikhali ukumelana, gqoka ukumelana. Izinto zepulasitiki kufanele zikhethelwe izidingo ezahlukahlukene nokunemba kwesikhunta kufanele kunqunywe.

4. high voltage ukumelana ugesi ibhokisi okuhlangana.

Izinhlobo ze-Resin: ABS, ABS / PC, Inayiloni

Ibhokisi lokuhlangana lisetshenziselwa imvelo enamandla aphezulu, njengamakhabethe kagesi, amabhokisi wokulawula kagesi, amadivayisi wokusabalalisa. Ukufakwa okuhle nokuvikela ukuguga kuyadingeka. Inayiloni namanye amapulasitiki wobunjiniyela ngokuvamile akhethiwe.

5. Umsebenzi omkhulu webhokisi le-photovoltaic junction box ukuxhuma nokuvikela imojuli ye-photovoltaic yelanga, uqhuba okwenziwa yimodyuli ye-photovoltaic. Njengengxenye ebalulekile yemodyuli yeseli yelanga, ibhokisi lenhlanganisela yemodyuli ye-photovoltaic ngumkhiqizo ophelele ohlanganisa ukwakhiwa kukagesi, ukwakheka kwemishini nokusetshenziswa kwempahla. Inikeza abasebenzisi uhlelo lokuxhuma oluhlanganisiwe lwemodyuli ye-solar photovoltaic.

6. Ibhokisi lokuhlangana elingangenwa ngamanzi.

Izinhlobo ze-Resin: ABS, ABS / PC, PPO

Kunezindinganiso ezimbili zokuvimbela ukungena kwamanzi.

A. Ukusaphazeka kwangaphandle okufishane, okungukuthi amanzi ngeke athelwe ngqo kumkhiqizo.

B. Umkhiqizo ucwiliswa emanzini.

Izidingo zamanzi ikakhulu zincike ekwakhiweni kwezingxenye zepulasitiki, njenge:

Bhala indandatho yokufaka uphawu ekuhlanganeni noma ekuvuleni;

Ukushisela kwe-Ultrasound kwamalunga amabili:

Integral umjovo udini.

Ibhokisi lokuhlangana elingangenwa manzi

Ibhokisi lokuhlangana lepulasitiki langaphandle

Ibhokisi lokuhlangana elingaphakathi

Tee ibhokisi lokuhlangana kwepulasitiki

Ukusetshenziswa okujwayelekile kwebhokisi lokuhlangana kwepulasitiki

Inayiloni ibhokisi lokuhlangana lepulasitiki

Izidingo zokusetshenziswa kwamabhokisi okuhlangana kagesi

Amabhokisi okuhlangana kagesi ahlobene kakhulu nogesi futhi kufanele ahambisane nezinga lokuphepha noma izidingo ezifanele, ikakhulu:

1. Ukumelana nesimo sezulu: ukumelana namazinga okushisa aphezulu naphansi, umswakama

2. Ukufakwa Kukagesi

3. Ukumelana namandla aphezulu omoya, ukulahleka kwe-dielectric njalo nokulahleka kwe-dielectric: Kungasebenza kumandla aphezulu kagesi noma aphansi, aphakathi naphakathi nensimu kagesi.

4. Ukushabalalisa ukushisa: ukushisa okwenziwe izingxenye zangaphakathi kungakhishwa ngokushesha okukhulu.

5. I-Flame retardant: Akulula ukubhebhethekisa umlilo.

6. Imisebe ye-Anti-ultraviolet: Lapho ibhokisi lokuhlangana likagesi lisendaweni ekhanyayo noma endaweni engaphandle, ngeke liguga futhi lehluleke ngenxa yemisebe ye-ultraviolet.

7. Ukumelana nokugqwala: Emvelweni we-asidi, i-alkali nosawoti, ngeke kudale umonakalo futhi kulimaze, futhi kungasebenza isikhathi eside.

8.Ukuvalwa nokungena kwamanzi: uyakwazi ukusebenza endaweni emanzi noma yamanzi

9. Ukuvikelwa kwemvelo: Qinisekisa ukuthi izinto ezisetshenzisiwe zizokhipha izinto ezinobuthi noma zibheme lapho zifudunyezwa noma zishiswa, okuzolimaza impilo yabantu.

Ukucatshangelwa Kokuklanywa Kwebhokisi Lokuxhuma Ngogesi

1. Ukukhethwa kwempahla: Njengamanje, izinkambu eziyinhloko zohlelo lokusebenza lwemikhiqizo yebhokisi lokuhlangana elingangeni manzi ziyindawo yokwakha enokhahlo nendawo evulekile. Ukumelana nomthelela, amandla omthwalo we-static, impahla yokufaka, * okungewona ubuthi, * ukumelana nokuguga, ukumelana nokugqwala kanye nokugcina ilangabi kwezinto kufanele kubhekwe lapho kubhekwa ukusebenza kokuphepha kwemikhiqizo. (Ukusebenza okungeyona into enobuthi kukhathazeke kabanzi, ikakhulukazi ngoba uma imikhiqizo yebhokisi lokuhlangana elingangeni manzi esimweni somlilo, umlilo ngeke uvule amagesi anobuthi futhi ayingozi, imvamisa uma kwenzeka kuba nomlilo ngenxa yokuhogela inqwaba yamagesi anobuthi futhi ukufa kubange iningi.

2. Ukwakhiwa kwesakhiwo: Ukucatshangelwa kufanele kunikezwe amandla amakhulu, ubuhle, ukucubungula okulula, ukufakwa okulula nokuvuselelwa kabusha kwamabhokisi enhlanganisela engenamanzi. Njengamanje, imikhiqizo yebhokisi lokuhlangana elingangenwa ngamanzi elenziwa abakhiqizi abakhulu bamazwe aqukethe izingxenye zensimbi, ezingenza lula inqubo yokutakula umkhiqizo. Kodwa-ke, izinto ezisetshenziswa abakhiqizi abaningi basekhaya zehlukile, futhi izakhiwo ezilwa ne-wax zezinto zokusebenza zimbi. Ngokuvamile, ukufakwa kwethusi kufakwa esokeni lokufaka lebhokisi lokuhlangana elingenamanzi ukukhulisa amandla wokufaka, okuzokhulisa isikhathi nezindleko zenqubo yokubuyisa impahla. Izinkinga ezinjalo zingaxazululwa ngokukhetha izinto zokusetshenziswa ezinezinkomba zokusebenza eziphakeme ezinikezwa ngabakhiqizi abajwayelekile.

3. Ubukhulu Bodonga: Ngokuvamile, lapho kubhekwa izindleko eziphelele zomkhiqizo, ubukhulu bomdonga womkhiqizo kufanele bancishiswe ngangokunokwenzeka ukuze kuhlangatshezwane nokumelana nomthelela nokumelana nomswakama komkhiqizo. Ekudizayinweni kwamabhokisi ehlanganiso angangenwa ngamanzi omhlaba, ubukhulu bezindonga ze-ABS nezinto ze-PC ngokuvamile buphakathi kuka-2.5 no-3.5 mm, ingilazi ye-fiber polyester eqinisiwe imvamisa iphakathi kuka-5 no-6.5 mm, futhi ubukhulu bodonga bezinto ezifakwe i-aluminium die-cast ngokuvamile ziphakathi 5 no-6.5 mm. Kuphakathi kuka-2,5 no-6. Ukujiya kodonga lwento kufanele kuklanyelwe ukuhlangabezana nezidingo zokufakwa kwezinto eziningi nezinye izinsimbi.

4.Ukukhethwa kwempahla yendandatho yokubeka uphawu: Okwemikhiqizo yebhokisi lokuhlangana okungangenwa manzi, izinto zokubopha izindandatho ezisetshenziswa kakhulu yilezi: IPUR, EPDM, Neoprene, Silicon. Ububanzi bezinga lokushisa, ukumelana kokungezwani, isilinganiso sokunwetshwa, ubulukhuni, ukuminyana, isilinganiso sokuminyaniswa kanye nokumelana kwamakhemikhali kufanele kubhekwe lapho kukhethwa indandatho ebekiwe.

5. Ikhava yesikulufu sokuxhuma amanzi engaguquki: Lapho ikhava yebhokisi lokuhlangana elingangeni manzi nesisekelo kuhlanganisiwe, ingxenye esemqoka ibhawodi. Ukukhethwa kwempahla yemishudo nakho kubaluleke kakhulu. Izinto ezisetshenziswa kakhulu yi-PA (inayiloni) noma i-PA alloy, futhi insimbi engagqwali ngokuthepha isikulufa nayo ingasetshenziswa. Amandla esakhiwo kufanele acatshangelwe ekwakhiweni kwesikulufa esiphezulu. Ngoba abasebenzisi abahlukahlukene basebenzisa izindlela ezahlukahlukene futhi bahlangabezana nezidingo ezahlukahlukene, njengokufakwa kwesikulidilayiva kagesi kanye nokufakwa ngesandla, amandla we-torque wesikulufu kufanele acatshangelwe ekwakhiweni.

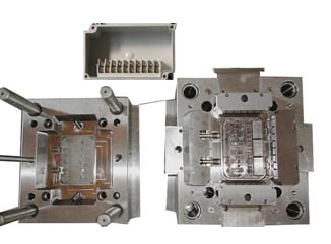

Isikhunta sebhokisi legesi kagesi kanye nokubumba

Izingxenye eziyinhloko zebhokisi lokuhlangana izindlu zepulasitiki nesembozo. Zenziwe ngendlela yomjovo wepulasitiki. Ithuluzi umjovo isikhunta.

Ukwakhiwa kwesikhunta sebhokisi lokuhlangana kwebhokisi lokuhlangana kuxhomeke ekwakhiweni kokuklanywa nokukhishwa kwebhokisi lokuhlangana, elinquma ukwakheka kwesakhiwo sesakhiwo sesikhunta nomgodi.

Insimbi nobulukhuni bokufakwa kwesikhunta kuncike kusakhiqizi se-resin epulasitiki, ukuthungwa komhlaba komkhiqizo nempilo ebhekiswe kulowo obunjiwe. I-Steel P20 ivame ukusetshenziselwa okokufaka ukufaka isikhunta kuma-oda ajwayelekile, futhi i-S136 nayo isetshenziselwa ukucwebezela okuphezulu. Kuma-oda amakhulu emikhiqizo, isikhunta semigodi eminingi siyadingeka ukukhulisa umthamo wokukhiqiza.

Junction ibhokisi plastic umjovo isikhunta

IMestech iqongelele ulwazi olucebile lokwenza isikhunta nomjovo wokukhiqizwa kwamabhokisi enhlanganisela yamakhasimende amaningi. Uma unesidingo sezingxenye zepulasitiki ebhokisini lokuhlangana, sicela uxhumane nathi.