Plastic umjovo udini iyona esetshenziswa kakhulu omunye phakathi udini plastic. Izingxenye ezibunjiwe zepulasitiki zisetshenziswa ku-elekthronikhi, ugesi, ugesi, ezokwelapha, ezokuthutha, imoto, ukukhanyisa, ukuvikela imvelo, ezokuphepha, izinto zasendlini, imishini yezemidlalo nezinye izimboni nemikhiqizo.

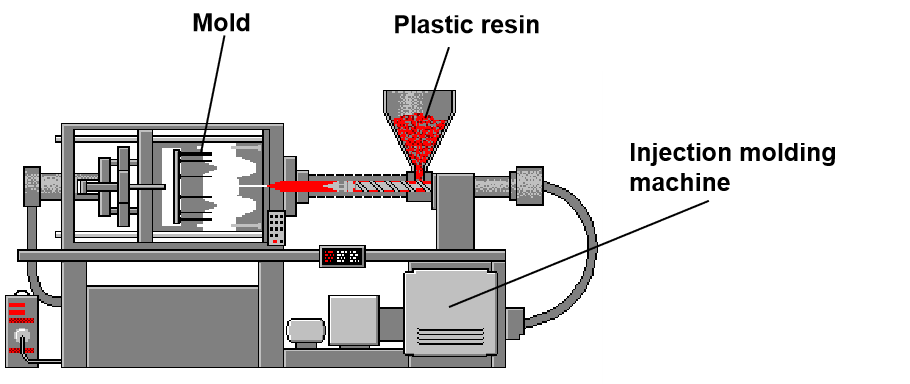

Kuyini umjovo udini? Plastic umjovo udini inqubo yokukhiqiza yokukhiqiza izingxenye ebangeni elithile lokushisa, ngokusebenzisa isikulufu eshukumisa izinto zepulasitiki ezincibilikile ngokuphelele, umjovo wokucindezela okuphezulu emgodini wesikhunta, ngemuva kokupholisa nokwelapha, ukuthola indlela yokubumba. Le ndlela ilungele ukukhiqizwa kweqoqo lezingxenye eziyinkimbinkimbi futhi ingenye yezindlela zokucubungula ezibalulekile. Kunezigaba ezi-6: ukuvala isikhunta, umjovo wepulasitiki ocibilikile, ukunakekelwa kwengcindezi, ukupholisa, ukuvulwa kwesikhunta kanye nomkhiqizo. Isivinini, ingcindezi, isikhundla (unhlangothi), isikhathi nokushisa kuyizinto eziyisihlanu ezibalulekile zomjovo womjovo.

Izinto ezintathu zophiko lokukhiqiza umjovo

Isicelo imikhiqizo umjovo udini

(1) kwimikhiqizo ye-Electronics: .Ukuxhumana kwemikhiqizo ye-elekthronikhi kanye ne-electronics yabathengi (izindlu zepulasitiki, indawo ebiyelwe, ibhokisi, ikhava) Omakhalekhukhwini, ama-headphone, amathelevishini, izingcingo zevidiyo, imishini ye-POS, insimbi yomnyango.

(2) ezintweni ezisetshenziswa ekhaya: Umenzi wekhofi, i-juicer, ifriji, i-air conditioner, i-fan washer ne-oven microwave

(3) kwimishini kagesi: Imitha kagesi, ibhokisi elisebenza ngogesi, ikhabethe likagesi, isiguquli semvamisa, ikhava yokufaka kanye nokushintsha

(4) kwimishini namathuluzi okunakekelwa kwezempilo nezempilo: Amalambu okusebenza, i-sphygmomanometer, isirinji, ithawula, ibhodlela lemithi, i-massager, idivaysi yokususa izinwele, imishini yokuzivocavoca

(5) ezimotweni: Uhlaka lomzimba wedeshibhodi, ubakaki webhethri, imojuli yangaphambili, ibhokisi lokulawula, ifreyimu yokwesekwa kwesihlalo, i-placenta eseceleni, isidutshwa, ubhampa, ikhava ye-chassis, isithiyo somsindo, uhlaka lomnyango ongemuva.

(6) Kuma-equipments ezimboni: Iphaneli yensimbi yomshini, igiya, iswishi, ukukhanyisa.

(7) Izinsimbi zethrafikhi nemishini yezeMoto (ikhava yesibani, indawo ebiyiwe) Isibani sesiginali, uphawu, isihloli sotshwala.

Izinto ezintathu zophiko lokukhiqiza umjovo

Isikhunta, umshini wokubumba umjovo nezinto zokwenziwa zepulasitiki kwakha iyunithi eyisisekelo yokubumba umjovo. Isikhunta nomjovo wokubumba umshini yimishini yokukhiqiza, futhi impahla eluhlaza eyenziwe ngepulasitiki isetshenziselwa ukwakha umkhiqizo womkhiqizo.

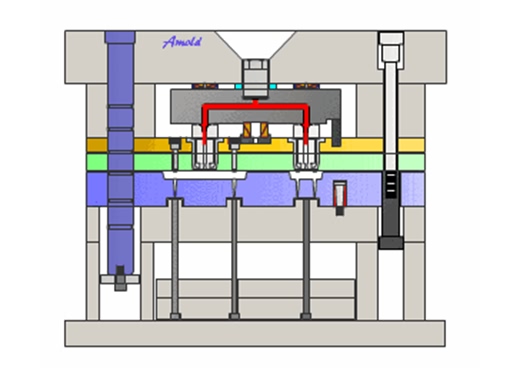

1. umjovo isikhunta

Injection isikhunta uhlobo lwethuluzi lokukhiqiza imikhiqizo yepulasitiki; futhi kuyithuluzi lokunikeza imikhiqizo yepulasitiki ukwakheka okuphelele nosayizi oqondile. Umjovo udini uhlobo ukucutshungulwa indlela esetshenziswa ukukhiqizwa batch of ezinye izingxenye eziyinkimbinkimbi. Ngokuqondile, ipulasitiki elicibilikile lifakwa embotsheni yesikhunta ngomshini wokubumba umjovo ngaphansi kwengcindezi ephezulu, futhi umkhiqizo obunjiwe utholakala ngemuva kokupholisa nokwelapha. Injection isikhunta ingahlukaniswa ngezinhlobo ezahlukene ngokuya ngesakhiwo esihlukile sesikhunta, izidingo zomklamo womkhiqizo, imodi yokukhiqiza nokufakwa nemodi yokusebenzisa.

Ngenxa yezindleko eziphakeme zokukhiqiza zesikhunta, kepha impilo yazo ende yokusebenza nokusebenza kahle kokukhiqiza, kuvame ukusetshenziselwa ukukhiqizwa kwezinto ngobuningi. Injection isikhunta isetshenziselwa ukukhiqizwa ngobuningi izingxenye plastic. Inani elikhulu kakhulu eliphezulu-imikhiqizo epulasitiki, ukwabelana kakhulu izindleko zokukhiqizwa isikhunta, ngakho izindleko yokukhiqiza olulodwa umkhiqizo umjovo udini liphansi kakhulu kunezinye izindlela zokucubungula. Kunezigaba ezintathu zokwakhiwa kwesikhunta nokuqinisekiswa kwesikhunta.

(1) Isikhunta design:

Isikhunta design kusekelwe design umkhiqizo, ukusetshenziswa software design, ngokusho isikhunta yokukhiqiza ezingeni ukucutshungulwa ngomshini futhi umjovo udini inqubo izici, ukwakheka lonke isikhunta indlela, izingxenye.

(a) Isinyathelo sokuqala ukuhlaziya ukwakheka kwemikhiqizo yepulasitiki

(b) Isinyathelo sesibili ukukhethwa kwezinto zokufa

(c) Isinyathelo sesithathu ukwakhiwa kwesikhunta

(d) Isinyathelo sesine ukuklanywa kwezingxenye zesikhunta

(2) isikhunta ukucutshungulwa

Isikhunta ukucubungula ikakhulukazi ngokucubungula ngomshini ukuqedela ukubuyekezwa komdwebo → ukulungiswa kwempahla → ukucubungula → ukucubungula isisekelo sesikhunta → ukucubungula okuyisisekelo sokucubungula → ukucubungula kwe-electrode → izingxenye zesikhunta ukucubungula → ukuhlolwa → ukuhlangana → isikhunta ezindizayo

Umjikelezo wokucubungula wesikhunta somjovo uncike ebunzimeni nasezingeni lokucubungula isikhunta. Umjikelezo wokukhiqiza ojwayelekile uyizinsuku zokusebenza ezingama-20-60. Umshini osetshenziswa ekubunjweni kwesikhunta: i-CNC, i-lathe, umshini wokugaya ojwayelekile, i-grinder yaphezulu, i-EDM, i-WEDM, kanye nokuhlangana kwamathuluzi esandla, amathuluzi wokulinganisa, njll.

(3) Izinhlobo umjovo isikhunta:

Injection isikhunta ingahlukaniswa ngezinhlobo ezahlukene ngokuya ngesakhiwo sesikhunta, izidingo zomklamo womkhiqizo, imodi yokukhiqiza nokufakwa nemodi yokusebenzisa.

(a) Isikhunta samapuleti amabili: ekubunjweni komjovo, isikhunta esihambayo kanye nesikhunta esinqunyiwe sesikhunta kuyahlukaniswa, bese izingxenye zepulasitiki zikhishwa, ezaziwa nangokuthi isikhunta sepuleti esiphindwe kabili. Kuyinto elula kakhulu futhi eyisisekelo yomjovo wepulasitiki. It kungenziwa yakhelwe njengoba olulodwa ingaphakathi umjovo isikhunta noma multi ingaphakathi umjovo isikhunta ngokusho funa. Kuyinto esetshenziswa kabanzi umjovo isikhunta. Isikhunta for olulodwa noma multi ingaphakathi umjovo udini,

(b) Isikhunta sepuleti ezintathu: esaziwa nangokuthi isikhunta sokuvalelisa kabili. Uma kuqhathaniswa nesikhunta sangaphandle somjovo owodwa, isikhunta sokuhlukaniswa okumbili okunezelwa singeza isiqeshana esihamba kancane ezingxenyeni ezingaguquki zesikhunta sepulangwe lesango lephuzu. Ngenxa yokwakheka kwayo okuyinkimbinkimbi nezindleko eziphezulu zokukhiqiza, imvamisa ayisetshenziswa ekubunjweni kwezingxenye ezinkulu.

(c) Isikhunta somgijimi oshisayo: isikhunta somgijimi oshisayo sisho isikhunta esisebenzisa idivayisi yokushisa ukwenza ukuncibilika esiteshini kungagxilisi ngaso sonke isikhathi. Ngoba kusebenza kahle kakhulu kunokwenziwa kwesikhunta kwendabuko, nokugcina izinto zokusetshenziswa ezingashisi, umgijimi oshisayo oshisayo kangaka emazweni anamuhla athuthukile ezimbonini nasezifundeni asetshenziswa kabanzi. Uhlelo lomgijimi oshisayo lunolunye uhlelo lomgijimi oshisayo ngaphezu kwesikhunta esivamile, ngakho izindleko ziphakeme.

(d) Isikhunta sombala emibili: ngokuvamile kubizwa ngezinhlobo ezimbili zezinto zepulasitiki kumjovo ofanayo wokujova umshini wokujova, ukubumba okubili, kepha isikhunta somkhiqizo kanye kuphela. Ngokuvamile, le nqubo yokubumba ibizwa nangokuthi umjovo ophindwe kabili, ovame ukuqedwa ngeqoqo lesikhunta, futhi udinga umshini okhethekile wokubumba umjovo wemibala emibili.

(4) Uhlelo olungaphansi lokwakhiwa komjovo womjovo lumi kanje

Isikhunta somjovo ngokuvamile sakhiwe yizinhlelo ezingaphansi ezilandelayo:

(a) Uhlelo lweGating. Kubhekiswa kusiteshi sokugeleza kwepulasitiki esikhunjeni kusuka kumbhobho womjovo kuya emgodini. Uhlelo olujwayelekile lokungena luqukethe i-sprue, i-distributor, isango nomgodi obandayo.

(b) Ukuhlukaniswa okuceleni kanye nendlela yokudonsa eyinhloko.

(c) Indlela yokuqondisa. Esikhunjini sepulasitiki, ikakhulukazi inomsebenzi wokubeka, ukuqondisa nokuthwala ingcindezi ethile yohlangothi ukuqinisekisa ukunemba kokuvala nokulungiswa kwesikhunta. Umshini wokuqondisa wokufa uqukethe insika yomhlahlandlela, umkhono wokuqondisa noma umgodi wokuqondisa (uvulwe ngqo kuthempulethi) nendawo yokuma kwesigaxa.

(d) Indlela yokukhipha / yokucekela phansi izakhiwo. Kubandakanya ukuphuma nokukhishwa okuyisisekelo. It is ikakhulukazi esetshenziselwa ukukhipha izingxenye kusuka isikhunta. Iqukethe induku ye-ejector noma i-pipe jacking noma ipuleti yokuphusha, ipuleti ye-ejector, induku ye-ejector induku ehleliwe, induku yokusetha kabusha nenduku yokudonsa.

(e) Uhlelo lokulawula izinga lokushisa. Ukupholisa nokushisa amadivayisi.

(f) Uhlelo lokukhipha.

(g) Izingxenye zokubumba zibhekisela ezingxenyeni ezakha umgodi wesikhunta. Ngokuyinhloko kufaka phakathi:

(h) Izingxenye ezihleliwe nezifakiwe. .

(5) Izinto zesikhunta

Isikhunta seplastiki sifaka isikhunta se-thermoplastic kanye ne-thermosetting plastic mold. Insimbi yesikhunta sepulasitiki iyadingeka ukuthi ibe nezakhiwo ezithile njengamandla, ubulukhuni, ukumelana nokugqoka, ukuzinza okushisayo nokumelana nokugqwala. Ngaphezu kwalokho, kuyadingeka futhi ukuthi kube nokusebenziseka okuhle, njengokuphathwa kokushisa okuncane, ukusebenza okungcono kokucubungula, ukumelana nokugqwala okungcono, ukusebenza okungcono kokugaya nokupholisha, ukusebenza kangcono kokulungisa i-welding, ukuqina okuphezulu, ukuqhuba kahle kokushisa nokuqina okuzinzile nokuma kokusebenza izimo.

Hlobo luni lomjovo osetshenziswa ekubunjweni komjovo unethonya elikhulu ekukhetheni isikhunta sensimbi. Uma i-ejenti yokuqinisa noma enye i-ejenti yokuguqula ingeziwe, njenge-fiber fiber, ukulimala kwesikhunta kukhulu, ngakho-ke ukukhethwa kwezinto ezibonakalayo kufanele kubhekwe njengokuqondakalayo. Izinto eziqinile zepulasitiki ze-asidi yi-PVC, i-POM, i-PBT; izinto zepulasitiki ezibuthakathaka ziyi-PC, i-PP, i-PMMA, i-PA. Ngokuvamile, i-S136, 1.231, 6420 kanye nezinye izinsimbi zesikhunta zikhethelwa amapulasitiki aqinile, kanti i-S136, 1.2316420, i-SKD61, i-NAK80, i-pak90718, njll ingakhethwa kuma-plastiki abuthakathaka. Izidingo zokubukeka kwemikhiqizo nazo zinethonya elikhulu ekukhetheni izinto zokubumba. Ezingxenyeni ezisobala nemikhiqizo ene-mirror surface polishing, izinto ezitholakalayo yi-S136, 1.2316718, NAK80 ne-pak90420. Isikhunta esinezidingo zokucaca okuphezulu kufanele sikhethe i-S136, silandelwe ngu-420. Uma kuhlangatshezwana nezidingo zomkhiqizo ngaphandle kokucabangela intengo nezindleko, kungahle kungabi ngumklami omuhle, izindleko zokukhiqiza isikhunta nakho kuyinto ephambili

2.1njection ukubumba Equipments

(1). Umjovo udini umshini:

imishini esemqoka yokubumba yokwenza amaplastikhi e-thermoplastic noma ama-thermosetting abe yizimo ezahlukahlukene zemikhiqizo yepulasitiki ngepulasitiki yokubumba isikhunta umshini wokubumba umjovo ovundlile, umshini wokubumba umjovo oqondile, umshini wokujova ngemibala emibili, umshini ogcwele wokujova ngogesi Nokho, noma ngabe unjani umjovo udini umshini, imisebenzi yayo eyisisekelo ezimbili:

(a) Shisisa ipulasitiki ukuze incibilike.

(b) Kusetshenziswa ingcindezi ephezulu kupulasitiki oncibilikisiwe ukukhipha nokugcwalisa umgodi. Imingcele eyinhloko yomshini wokubumba umjovo yilezi: ukubambelela ngamandla, ivolumu enkulu yomjovo, ubukhulu obukhulu nobuncane besikhunta, ukushaya okuhamba phambili, ukudonsa induku, ukudonsa unyawo kanye nengcindezi yokukhipha. Ezingxenyeni ezinobukhulu obuhlukile, izakhiwo nezinto zokwakha, kanye nesikhunta samasayizi nezinhlobo ezahlukahlukene, kufanele kukhethwe amamodeli ahlukile nemingcele yemishini yokubumba umjovo. Umshini wokufaka umjovo kagesi ogcwele unezinzuzo zejubane elikhulu lomjovo, ukulawula okuqondile nokusebenza kahle kokukhiqiza. Isetshenziselwa umjovo udini ezinye izingxenye ngokunemba.

(2) Okokusebenza okusizayo:

(a) I-manipulator yomshini wokubumba umjovo iyithuluzi lokukhiqiza elizenzekelayo elingalingisa eminye imisebenzi yezitho zomuntu ezingaphezulu, futhi liyilawule ngokuzenzakalela ukuhambisa imikhiqizo noma ukusebenzisa amathuluzi ngokuya ngezimfuneko ezibekiwe ngaphambili. I-manipulator ingaqinisekisa ukufana komjikelezo wokusebenza, ithuthukise ikhwalithi futhi iyenze iphephe. Nge ukuthuthukiswa okusheshayo plastic ukucutshungulwa umkhakha e-China, izinga ezishintshayo ka umjovo udini imishini isiba ephakeme futhi ephakeme. Imishini yokubumba umjovo yanamuhla ivame ukufakwa ngama-manipulators ukuthuthukisa ukusebenza kahle kokukhiqiza.

(b) Isifudumezi samafutha / okushisa amanzi: ukufudumeza noma ukupholisa ngoketshezi olugeleza phakathi kwesikhunta, ukushisa kwesikhunta okwandayo, ukukhulisa ikhwalithi ephezulu, noma ukunciphisa ngokushesha ukushisa kwesikhunta ukwenza ngcono umkhiqizo.

(c) Isomisi sokukhipha inyumbazane: susa umswakama ezintweni zepulasitiki ngokufudumeza nangokufutha.

Umjovo isikhunta workshop

Umugqa wokukhiqiza umjovo wokujova

Izingxenye zepulasitiki zokudweba umugqa

Izinto ze-3

Izinhlaka zepulasitiki ezisetshenziswa ekubunjweni komjovo: Ngezansi kukhona ama-thermoplastics ajwayelekile kakhulu asetshenziswa ekubunjweni komjovo: I-Acrylonitrile Butadiene Styrene, i-Acrylonitrile Butadiene Styrene (ABS), iyi-polymer e-opaque thermoplastic ne-amorphous polymer. ... I-Polyethylene. ... I-Polycarbonate. ... I-Polyamide (Inayiloni) ... I-High Impact Polystyrene. ... I-Polypropylene

| Izinto | Ubuningi | Isikhunta Ukuncipha |

Isici | Isicelo |

| I-Gram / cm3 | % | |||

| ABS(Isitayela se-Acrylonitrite Butadiene) | 1.04 ~ 1.08 | 0.60 | Usayizi ozinzile, izakhiwo ezinhle eziphelele zemishini,i-electroplating elula, ukubunjwa kwe-injection elula | izindlu zepulasitiki zemikhiqizo kagesi |

| I-PC (I-Polycarbonate) | 1.18 ~ 1.20 | 0.50 | Amandla omthelela omuhle, usayizi ozinzile nokufakwa kahle.Ukumelana nokugqwala okubi nokugqoka ukumelana | izindlu zepulasitiki, ikhava evikelayo, izingxenye ezincane zokudlulisa zemikhiqizo kagesi, imikhiqizo kagesi |

| PMMA(I-Polymethyl methacrylate) | 1.17 ~ 1.20 | 0.60 | It has transmittance okuhle kuka-92% namandla amahle aphelele womshini.Amandla we-notch amandla aphansi, kulula ukucindezela ukuqhekeka | Ilensi engabonakali nezimpawu zokudayela zensimbi |

| I-PP(Polypropylene) | 0.89 ~ 0.93 | 2.00 | Ine-shrinkage ephezulu, ukumelana nomswakama,ukumelana nokushisa okuphezulu futhi akulula ukudabuka.Phansi Wear ukumelana, kulula ukuguga, ukusebenza okuncane kokushisa okuphansi | Iziqukathi zokudla, i-tableware, amabhokisi we-oven microwave, iziqukathi zezokwelapha |

| (i-chloride) | 1.38-1.41 | 1.50 | Okuqinile, ukumelana nokugqoka, ukwahlukanisa okuhle, kwakha ukusebenza okunzima kakhulu, okungalungile kokushisa okuphezulu | Ukwenza amapayipi namaphrofayli |

| Inayiloni | 1.12 ~ 1.15 | 0.7-1.0 | Kunzima, kuyamelana nokugqoka, kuyamelana namanzi, ukumelana nokukhathala, ukwahlukanisa okuhle. Ukuncipha okuphezulu, ukuqondisa | Izingxenye zomshini, izingxenye zamakhemikhali, izingxenye zokudlulisa |

| I-POM (Polyacetel) | 1.42 | 2.10 | Izici ezinhle kakhulu zomshini, amandla aphezulu nobulukhuni, gqoka ukumelana nokuphikisana nomthelela. Ukuzinza okushisayo okungekuhle | Izingxenye zomshini, izingxenye zamakhemikhali, izingxenye zokudlulisa, izingxenye zokushayisana kanye nezingxenye zokudlulisa ezisebenza ekamelweni lokushisa |

| I-TPU(Thermoplastic Polyurethane) | 1.05 ~ 1.25 | 1.20 | Elastomer, gqoka nemithi, uwoyela nemithi, ukuqina okuphezulu nokuphansi kokushisa, okungenabuthi | Kabanzi kwezokwelapha, ukudla, imikhiqizo kagesi nendawo ephansi yokushisa |

Inqubo yokubumba umjovo yinqubo yokuthi izinto ezingavuthiwe ezincibilikisiwe zicindezelwe, zijojowe, zipholile futhi zehlukaniswe ukukhiqiza ukwakheka okuthile kwezingxenye eziqediwe. Inqubo ejwayelekile yokubumba umjovo wezingxenye zepulasitiki ikakhulu ifaka izigaba ezi-7. : Ukumiswa kwepharamitha -> ukuvala isikhunta-> ukugcwalisa -> (kusizwe igesi, kusizwe amanzi) ukucindezela ukugcina -> ukupholisa -> ukuvulwa kwesikhunta -> ukudiliza.

Ijubane, ingcindezi, isikhundla (unhlangothi), isikhathi nokushisa kuyimingcele emihlanu yokhiye wenqubo yokubumba umjovo. Ekukhiqizeni umjovo wokubumba, ikakhulukazi ukulungisa iphutha lawa ma-parameter ukuze uthuthukise futhi uthole usayizi ofanelekile nokubukeka.

Eziyisikhombisa ejwayelekile umjovo udini ubuchwepheshe

1. Double umjovo udini

2. Umjovo wokubumba ngokweqile

3. Hot umgijimi umjovo udini

3. IMD: in-isikhunta umhlobiso umjovo

4. Ukujova izingxenye ezinkulu

5.Ukubumba ngomjovo kwezingxenye eziqokomisayo

6.Ukubumba umjovo wezingxenye zezimoto

7. Izacile odongeni izingxenye umjovo

Ukucubungula okuthunyelwe

Singahlinzeka ngomjovo wakho wezingxenye zepulasitiki ezibunjiwe ezinhlobonhlobo ezahlukahlukene zomjovo ophuculwayo ongafakwa futhi ngevolumu engu-0.1gram-10kgs oyidingayo. Ngaphezu kwalokho, singakwazi ukufaka okokufaka okwenziwe ngentambo ngaphezulu, izixhumi zensimbi noma ezinye izingxenye zomjovo wepulasitiki ezibunjiwe ukuze unikeze umkhiqizo wakho isiphetho sobuchwepheshe. Ama-sub-assemblies nawo angadalwa njengengxenye yezinsizakalo zethu zepulasitiki zomjovo womjovo futhi ahlanganiswe nezidingo zakho. Okufanayo kusebenza ngezinqubo ezahlukahlukene zokuqeda, kufaka phakathi:

* Ukufakwa kwepulasitiki kwe-Chrome

* Ukudweba

* Ukucatshangelwa kwedijithali

* Ukuphrinta kwePad

* Ukuvikelwa kwe-RF

* Ukupakisha kanye ne-stillage's

* Ukulawulwa kwekhwalithi yomjovo we-Injection Siphinde sinikeze izinsiza ezisheshayo, prototyping kanye nezinsizakalo zokubumba.

Ukubumba ukukhubazeka nokuxazulula inkinga

Ngemuva kokubumba, kukhona umehluko othile phakathi kwezingxenye zepulasitiki namazinga wekhwalithi anqunywe kusengaphambili (amazinga wokuhlola), angakwazi ukuhlangabezana nezidingo zenqubo elandelayo. Lokhu ukukhubazeka kwezingxenye zepulasitiki, okuvame ukubizwa ngokuthi izinkinga zekhwalithi. Kufanele sifunde izimbangela zalokhu kungaphumeleli futhi sizinciphise okungenani. Ngokuvamile, lokhu kukhubazeka kubangelwa yizici ezilandelayo: isikhunta, izinto zokusetshenziswa, imingcele yenqubo, imvelo yemishini kanye nabasebenzi.

1.The ukukhubazeka ezivamile:

(1). Umehluko wombala: uma umbala wezingxenye zokujova ngomjovo uhlukile kusampula elilodwa elijwayelekile lombala ngamehlo enqunu, lizokwahlulelwa njengomehluko wombala ngaphansi komthombo wokukhanya ojwayelekile.

(2). Ukugcwaliswa okunganele (ukuntuleka kweglue): izingxenye zokubumba umjovo azigcwele, futhi kunamabhamuza, ama-void, izimbobo zokuncipha, njll., Ezingahambelani nesifanekiso esijwayelekile, esibizwa ngokushoda kweglue.

(3). Ukusonteka kokugoqeka: ukwakheka kwezingxenye zepulasitiki kuzophenduka futhi kusonteke ngemuva kokudilizwa noma esikhathini esizayo. Uma uhlangothi oluqondile lubheke ngaphakathi noma ngaphandle, noma ingxenye eyisicaba inezikhathi naphezulu, uma unyawo lomkhiqizo lungalingani, lubizwa ngokuthi yi-deformation, engahlukaniswa kube ukususwa kwendawo kanye nokusonteka konke.

(4). Amamaki womugqa we-Weld (imigqa): imikhondo eqondile ebusweni bezingxenye zepulasitiki, ezakhiwe ngokuhlangana kwamapulasitiki esikhunjeni, kepha ukuncibilika akuhlanganisiwe ngokuphelele lapho kuhlangana khona izindlela, ngakho-ke azinakufakwa zibe munye. Imigqa eminingi iqonde ngqo, isuka ekujuleni kuye ekujuleni. Lesi simo sinomthelela othile ekubukekeni nasezimpahleni zemishini.

(5). Ukugqashuka: ubuso bezingxenye ezibunjiwe zomjovo bunokuvunguza noma ifu njengokuvutha, noma ngaphakathi komkhiqizo obala kunephethini ye-wavy, ebizwa ngokuthi i-ripple.

(6). Ngaphezulu komphetho (flash, Cape).

(7). Ukungafani kobukhulu: ukuncipha kanye ne-warpage yezingxenye ezibunjiwe zomjovo enqubo yokubumba

2. Ukulawulwa kwekhwalithi nokwenza ngcono: Kubandakanya ubuchwepheshe nokuphathwa

(1). Izinga lobuchwepheshe: ukukhethwa okulungile kwezinto, ukwakheka kwesakhiwo somkhiqizo, ukukhethwa kwezinto zokwakha isikhunta, ukuklama ukwakheka kwesakhiwo sesikhunta ukwenza lula ukugcwaliswa, ukukhishwa kanye nokususwa kwezingxenye, ukulungiselelwa okufanelekile kwendawo yokuvalelisa, ukugeleza kwesiteshi nokungena kwerabha; ukusetshenziswa eziphambili imishini umjovo udini noma inqubo.

(2). Izinga Lokuphatha: ukulawulwa kwekhwalithi yezinto ezingenayo, ukwakhiwa kwezinqubomgomo nezindinganiso zekhwalithi ezisebenzayo, ukuqeqeshwa kwezobuchwepheshe, ukwenziwa kokucaciswa kwenqubo efanelekile, ukuqoshwa kwedatha nokuhlaziywa, nokusungulwa kohlelo lwekhwalithi yomsindo.

Inkampani yakwaMestech ikhiqiza amakhulu esikhunta nezigidi zemikhiqizo yepulasitiki yamakhasimende asekhaya nawomhlaba wonke ngonyaka. Uma ufuna ukwazi okwengeziwe noma ukubuza mayelana nekhotheshini mayelana plastic umjovo udini, sicela uxhumane nathi namuhla.