Amathiphu wezakhiwo zepulasitiki eziqondile nokuklanywa

Incazelo emfushane:

Precision izingxenye plastic design futhi umjovo udini kufanele iqale ezintweni zokwakha, ukwakheka kwezingxenye zezakhiwo, ukuklanywa kwesikhunta nokucubungula, umshini wokubumba umjovo, ukusebenza ngobungcweti nemvelo enhle yokukhiqiza.

Ngokuthuthukiswa komkhakha wesimanje, kunezinto zepulasitiki ezanda kakhulu. Ngasikhathi sinye, imikhiqizo yepulasitiki nayo isetshenziswa kabanzi ezimbonini ezahlukahlukene. Ikakhulukazi, izingxenye zepulasitiki eziya ngokuya zisetshenziswa. Manje ake sabelane nawe ngamathiphu wokuklanywa kwezingxenye zepulasitiki eziqondile nokubumba.

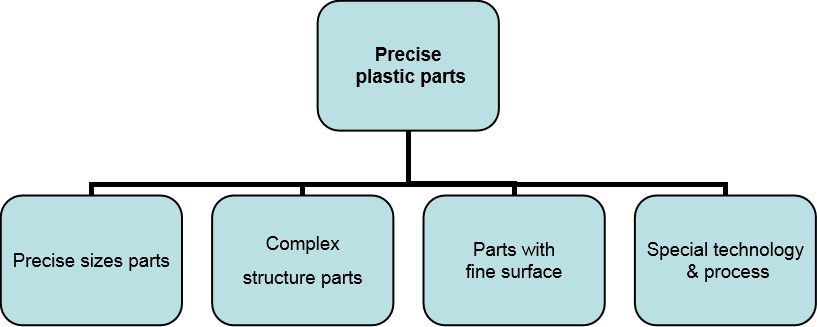

Ukuhlukaniswa kokunemba

izingxenye zepulasitiki:

1. Idizayini yezingxenye zepulasitiki eziqondile

(1) Izinhlobo ezijwayelekile zezingxenye zepulasitiki eziqondile

Izingxenye zokunemba ngakubuso obuphakeme, njenge: motor gear, worm gear, screws, bearings. Lezi zingxenye ezinembile zivame ukusetshenziselwa imishini yokudlulisa eqondile (njengamaphrinta, amakhamera, ama-vacuum cleaner, ama-robots, imishini ehlakaniphile, ama-UAV amancane, njll.). Kudinga ukudidiyela okunembile, ukunyakaza okubushelelezi, ukuqina nokungabi nomsindo.

Izingxenye B. ezibiyelwe ngomzimba omncane:

Imvamisa, udonga lwezingxenye zepulasitiki lungaphansi kuka-1.00mm, okungokwengxenye enezindonga ezincanyana. Izingxenye ezibiyelwe ngodonga zingenza ubukhulu bomkhiqizo bube buncane kakhulu. Kepha izingxenye zepulasitiki ezinodonga oluncane azikwazi ukugcwaliswa ngenxa yokupholisa nokuqina okusheshayo. Futhi izingxenye ezincanyana ezibiyelwe azikwazi ukumelana namandla of die and break in the die die. Ngakho-ke, ukwakheka kwezingxenye ezinobonda obuncane kufanele kukhethe izinto ezinezakhiwo ezingcono zomshini. Futhi ukwakheka okunengqondo, njengokulingana kodonga okufanayo, izingxenye azikwazi ukuba nodonga kakhulu. Ukufa okujulile, i-engeli enkulu. Kwezinye izingxenye ze-ultra-thin, umshini wokubumba umjovo wesivinini esikhulu uyadingeka.

Izingxenye ze-Optical:

Izingxenye ze-Optical zidinga ukusebenza okuhle kokuhambisa / ukukhanya, nokusimama okuhle kobukhulu nokuqina kokugqoka. Isibonelo, ukugobeka kobuso bamalensi we-concave ne-convex asetshenziswa kumaphrojektha kudinga ukunemba okuphezulu nokuqina. Kudingeka ipulasitiki ebonakalayo esobala efana ne-PMMA. Ngasikhathi sinye, ezinye izingxenye zokukhanya ezikhanyayo nazo zidinga ukwenza eminye imigqa emihle ebusweni bezingxenye ukwamukela ukukhanya noma ukukhanya noma ukuqeda ukukhanya.

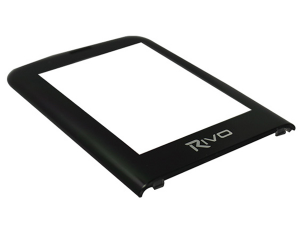

D. Ingcwecwe ephezulu:

Izingxenye ezicwebezelayo kakhulu zifaka izingxenye ezibonakalayo, kanye nezinye izingxenye ezidinga ukuphela okuphezulu komhlaba (isibuko ebusweni). Lolu hlobo lwezingxenye lusetshenziswa kabanzi kwimikhiqizo yabathengi ye-elekthronikhi, njengamagobolondo omakhalekhukhwini. Idizayini yalolu hlobo lwemikhiqizo kufanele icabangele izinto zepulasitiki ezinomkhuhlane omuhle, ukwakheka kobukhulu kanye nobuchwepheshe bokufa.

Izingxenye zepulasitiki ezingenamanzi

Imikhiqizo eminingi ye-elekthronikhi nekagesi idinga ubufakazi bamanzi, njengezibuko / amawashi angenawo amanzi / i-elekthronikhi yamasosha, imikhiqizo yangaphandle nezinsimbi ezinemvelo yamanzi manzi. Izindlela eziyinhloko zokuvimbela ukungena kwamanzi yizimpawu ezibethelwe ebusweni bangaphandle bomkhiqizo, njengezikhiye ezifakiwe, ama-jacks afakiwe, ukuvalwa kwemigodi, i-welding ye-ultrasonic, njll.

I-F.IMD / IML (in-mold-decoration, in-mold-label)

Le nqubo ukubeka ifilimu ye-PET emgodini wokujova umjovo nokuhlanganisa izingxenye zomjovo kubuchwepheshe bokucubungula bonke, obuzonamathela ngokuqinile ezingxenyeni zepulasitiki. Izici zemikhiqizo ye-IMD / IML: ukucaca okuphezulu, stereoscopic, akukaze kuphele; ukucaca kwamalensi wewindi afinyelela ku-92%; ingubo emelana nokugqokwa nemithi yempilo ende yokusebenza; Ukuqina kwemikhiqizo eyisihluthulelo ngesikhathi sokubumba umjovo, impilo esemqoka ingafinyelela ngaphezu kwezigidi eziyi-1.

Ingxenye yodonga lweplastikhi elincane

Iphaneli yepulasitiki ye-IMD / IML

Izingxenye zepulasitiki eziqondile

Ingxenye ebonakalayo / ikhava esobala

Ikesi elingenamanzi kabili

Ikesi eliqondile lemikhiqizo kagesi

Izindlu ezihlala njalo zesakhiwo esiyinkimbinkimbi

(2) .Amathiphu wokuklanywa kwezingxenye zepulasitiki eziqondile

A. ubukhulu bensimbi obufanayo Ekubunjweni komjovo, ipulasitiki isesimweni soketshezi isikhathi esifushane kakhulu, futhi ukufana kobukhulu bodonga lwezingxenye kunethonya elikhulu ekuhambeni kwe-velocity nasekuqondisweni kwepulasitiki. Ubukhulu bezingxenye buguquka kakhulu, obuzoletha uchungechunge lokukhubazeka kwekhwalithi njengokugcwalisa ukunganeliseki, ukusonteka, ukuncipha, amamaki we-weld, amamaki wokucindezela aqatha futhi acekeke, njll. Ngakho-ke, ubukhulu bodonga bezingxenye zepulasitiki eziqondile kufanele bube njengokufana kungenzeka ekwakhiweni. Ushintsho lokujiya akufanele lube lukhulu kakhulu, futhi ukwehla komthambeka noma i-arc kufanele kwenziwe kunguquko.

B. naka ukuhlangana phakathi kwezingxenye bese wenza izidingo ezifanele zosayizi ofanele. Ukuqinisekisa ukushintshana phakathi kwezingxenye, imvamisa sinikeza izidingo eziqinile zokunemba kwezingxenye ezithile. Kepha ezingxenyeni zepulasitiki, inezimo ezithile eziguquguqukayo nokuqina. Kwesinye isikhathi, inqobo nje uma ukwakheka kwesakhiwo kunengqondo, ukuphambuka kungalungiswa ngokusebenzisana phakathi kwezingxenye, ngakho-ke izinga lokunemba lingakhululeka ngokufanele ukunciphisa ubunzima bokukhiqiza. Isiqu.

C. Ukukhethwa kwezinto ezibonakalayo Kunezinhlobo eziningi zezinto zepulasitiki, futhi ukusebenza kwazo kuyehluka kakhulu. Ezingxenyeni zepulasitiki eziqondile, izinto ezinokuncipha okuncane / ukusonteka / ukuqina okuhle kobukhulu / ukumelana nesimo sezulu okuhle kukhethiwe ngokuya ngezidingo zokusetshenziswa. (a) ABS / PC ene-shrinkage ephansi isetshenziselwa ukumiselela i-PP ngokuncipha okuphezulu, ne-PVC / HDPE / LDPE nge-shrinkage ephansi. I-ABS + GF isetshenziselwa ukufaka esikhundleni se-ABS.PC + GF nge-PC. (b) Khetha i-PA66 + GF noma i-PA6 + GF esikhundleni se-POM noma i-PA66 ne-PA6.

D. cabanga ngokuphelele ngenqubo yokubumba.

(a) Kwigobolondo elijwayelekile lokujiya, ibhokisi noma izingxenye zediski, kungcono ukuklama i-microstrip arc ebusweni nokuqiniswa ngaphakathi ukuze kugweme ukusonteka.

(b) Ezingxenyeni ezi-ultra-thin, ubukhulu bezingxenye kufanele bufane, futhi izingxenye zangaphakathi akufanele zibe nezimbambo eziqinisa ngokujulile noma izakhiwo eziyinkimbinkimbi. Kunconywa ukusebenzisa umshini wokubumba umjovo wesivinini esiphezulu.

(c) Imibhobho eshisayo noma isikhunta somgijimi oshisayo kusetshenziselwa izingxenye ezinkulu ukwengeza isikhathi sokugcwalisa nokunciphisa ukwakha ukucindezeleka nokuguquguquka.

(d) izingxenye ezimbili zezinto ezenziwe ngezinto ezimbili, umjovo wombala ophindwe kabili esikhundleni somjovo weglue uyamukelwa.

(e) Kunconywa ukubumba okumi mpo ezingxenyeni ezinokufakwa okuncane kwensimbi.

E. Unendawo yokwenza ngcono. Ekuklanyweni kwezingxenye zepulasitiki eziqondile, kubalulekile ukuhlola ukuphambuka okungenzeka ekukhiqizeni okuzayo.

(3) Ukuqinisekiswa komklamo

Ukujova umjovo kunezindleko eziphezulu, isikhathi eside nezindleko eziphakeme zokuguqulwa, ngakho-ke ngemuva kokuphothulwa okuyisisekelo kokuklanywa kwengxenye, kuyadingeka ukwenza amasampula womzimba ukuqinisekisa ukwakheka, ukuze kutholakale ubunyoninco bamapharamitha wokuklanywa komkhiqizo, ukuthola izinkinga nokwenza ngcono ngaphambili.

Idizayini yokuqinisekisa ngokomzimba ifezwa ikakhulukazi ngokwenza imodeli yesibonelo. Kunezinhlobo ezimbili zokwenziwa kwesibonelo: ukucutshungulwa kwe-CNC nokuphrinta kwe-3D.

Ukusetshenziswa kwe-prototypes yokuqinisekisa ngokomzimba kudinga ukunakwa kulezi zici ezilandelayo:

Izindleko zokukhiqizwa kwe-A.CNC prototype ngokuvamile ziphakeme kunokuphrinta kwe-3D. Ezingxenyeni ezinkulu, izindleko zokucubungula i-CNC ziphansi kakhulu.

Okwezinto zokwakha nezakhiwo zemishini noma ukwelashwa kwendawo kanye nezidingo zomhlangano, kunconywa ukucutshungulwa kwe-CNC, ukuze kutholakale amandla amahle. Ezingxenyeni zosayizi omncane namandla aphansi, kusetshenziswa ukuphrinta kwe-3-D. Ukuphrinta kwe-3-D kuyashesha, futhi kushibhile kakhulu ezingxenyeni zosayizi omncane.

B. Ama-prototypes angaqinisekisa ukufaniswa komhlangano phakathi kwezingxenye, ahlole amaphutha wokuklama nokushiywa, futhi enze lula ukuthuthukiswa komklamo. Kodwa-ke, uhlobo oluthile alukwazi ukubonisa izidingo zobuchwepheshe besikhunta esakha, njenge-molding draft angle / shrinkage / deformation / fusion line nokunye

2. izingxenye zepulasitiki eziqondile zokubumba

(1) ukwenziwa kwesikhunta sepulasitiki (ukwakheka kwesikhunta) Isikhunta sekhwalithi ephezulu siyisihluthulelo sokwenza izingxenye eziqondile. Amaphuzu alandelayo adinga ukulandela.

A. khetha ngokunembile i-coefficient ye-shrinkage yezinto zepulasitiki. Isikhundla esinengqondo sezingxenye ekubunjweni.

B. impahla eyisisekelo yesikhunta izokhethwa njengezinto zensimbi ezinokuqina okuhle / ukugqoka ukumelana / ukumelana nokugqwala.

C. uhlelo lokuphakela isikhunta lisebenzisa i-Tsui eshisayo noma umgijimi oshisayo ngangokunokwenzeka, ukuze izingxenye zengxenye ngayinye yokufana kokushisa, zinciphise ukusonteka.

D. isikhunta kufanele sibe nesistimu enhle yokupholisa ukuqinisekisa ukuthi izingxenye zipholile ngokulinganayo ngesikhathi esifushane.

E. isikhunta kufanele sibe nokukhiya okuseceleni namanye amadivayisi wokubeka.

F. setha ngokufanelekile isikhundla sokukhishwa somshini we-ejector, ukuze amandla okukhipha izingxenye afane futhi angakhubazeki.

Ukwakhiwa kwesikhunta kanye nethuluzi lokuhlaziya elibalulekile (i-moldfow): Usebenzisa isoftware yokulingisa umjovo wokubumba ukulingisa umphumela wenqubo yokubumba umjovo ngaphansi kwamapharamitha wokusetha ahlukile, thola ukukhubazeka ekwakhiweni komkhiqizo nokwakhiwa kwesikhunta kusengaphambili, ukuthuthukisa nokuzilungiselela, futhi ugweme amaphutha amakhulu ekwakhiweni kwesikhunta ngezinga elikhulu kakhulu, elingaqinisekisa kakhulu ikhwalithi yesikhunta futhi anciphise izindleko zakamuva.

(2) qinisekisa isikhunta.

Izindleko zesikhunta esilula ziphansi kakhulu kunalezo zesikhunta sokukhiqiza. Ezingxenyeni eziqondile zepulasitiki zomjovo, kuyadingeka ukwenza isikhunta esilula ukuqinisekisa ukwakheka kwesikhunta ngaphambi kokwenza isikhunta sokukhiqiza esisemthethweni, ukuze uthole amapharamitha wokuthuthukisa ukwakheka kwesikhunta futhi uqinisekise impumelelo yesikhunta sokukhiqiza.

(3) isikhunta ukucutshungulwa

Izikhunta ezisezingeni eliphakeme kumele zenziwe ngemishini elandelayo enembile.

A. ithuluzi eliphezulu lomshini we-CNC

B. umshini ocwebezelayo wesibuko

C. ukusika kancane kwentambo

D. imvelo yokusebenza okushisa njalo

E. imishini yokuhlola edingekayo. Ngaphezu kwalokho, ukucutshungulwa kwesikhunta kufanele kulandele inqubo eqinile futhi kuncike kubasebenzi abasezingeni eliphakeme ukuze basebenze.

(4) Ukukhetha umjovo udini umshini

Izinsiza kusebenza zomjovo wokubumba izingxenye eziqondile zepulasitiki.

A. kufanele asebenzise imishini eqondile yokujova umjovo engeneminyaka engaphezu kwengu-5 yempilo yesevisi.

B. imvelo yefektri ihlanzekile futhi ihlanzekile.

C. ngezingxenye ezinomzimba omncane kakhulu, kufanele kube nomshini wokubumba umjovo onesivinini esikhulu.

D. umbala ophindwe kabili noma izingxenye ezingangeni manzi kufanele zibe nemishini emibili yokubumba umjovo wombala.

F. uhlelo lokuqinisekisa ikhwalithi yomsindo

(5) ukupakisha izingxenye eziqondile zepulasitiki

Ukupakisha okuhle kubalulekile ukuvikela ukuklwebheka, ukukhubazeka, uthuli kwezokuthutha, ukugcinwa kwezingxenye zepulasitiki eziqondile.

Izingxenye eziphezulu ze-gloss kufanele zinamathiselwe ngefilimu evikelayo.

Izingxenye ze-B.Izindonga ezincane kufanele zisongwe emaphaketheni akhethekile noma kugwebu, noma zihlukaniswe ngommese wephepha ukugwema ukucindezela okuqondile.

C. Izingxenye ezidinga ukuhanjiswa emabangeni amade akufanele zibekwe ngokukhululeka emabhokisini. Amabhokisi amaningi kufanele ahlanganiswe ndawonye ngezitaki nonogada.

Inkampani yakwaMestech inemishini nemishini yokwenza umkhiqizo oqondile wepulasitiki nomjovo wokubumba. Siyethemba ukukunikeza isikhunta sokwenza kanye nezinsizakalo zokukhiqiza zezingxenye zepulasitiki eziqondile.