ABS resin umjovo udini

Incazelo emfushane:

I-resin ye-ABS (i-acrylonitrile butadiene styrene) yi-polymer esetshenziswa kakhulu, kanti i-ABS resin injection molding yiyona evame kakhulu.

IMestech inolwazi olunzulu ekubunjweni komjovo we-ABS. Insiza yethu yokubumba i-ABS resin idala izingxenye ezisetshenziswe ezimbonini ezahlukahlukene kanye nezinhlobonhlobo zezicelo. Imishini yethu esezingeni eliphakeme izothatha umsebenzi wakho ngokushesha ukusuka ekuqaleni kuze kube sekugcineni ngemiphumela yekhwalithi. I-Plastic ABS resin (i-Acrylonitrile-Butadiene-Styrene) yi-polymer esetshenziswa kakhulu. I-ABS yaziwa kakhulu ngezindawo zayo ezinhle zokuzinza okuthe nkqo, isicwebezelisi, ukwakheka nokwelashwa kwendawo I-Injecton molding yiyona ndlela eyinhloko yokucubungula imikhiqizo ye-ABS.Impahla Engokwenyama ye-resin ye-ABS: Izinga Lokushisa Eliphezulu: 176 ° F 80 ° C Izinga Lokushisa Elincane: -4 ° F -20 ° C Autoclave Capable: No Melting Point: 221 ° F 105 ° C Tensile Strength: 4,300psi Hardness: R110 UV Resistance: Poor Color: Translucent Specific Gravity : 1.04  ABS resin Injection Molding IzinzuzoIzakhiwo 1.Good kagesi 2.Impact ukumelana 3.Excellent amakhemikhali ukumelana, ikakhulukazi amaningi acid nokhahlo, glycerine, ane-alikhali, ama-hydrocarbon amaningi futhi alcohol, usawoti wezinto 4.Ihlanganisa amandla, ukuqina nokuqina kokukodwa kwento 5.Ukuqina komthwalo 6. I-Lightweight 7.Processing solid dimensional and surface gloss are good, easy to paint, coloring, can also is sprayed metal, electroplating, welding and bonding and other secondary processing performance. 8. I-ABS ingenziwa ngemibala ehlukahlukene njengoba kudingeka. Uma engeza ilangabi cishe yizona ezisetshenziswa kabanzi okufakiwe noma i-anti-ultraviolet okufakiwe ku-ABS, ingasetshenziswa ukukhiqiza izingxenye zamadivayisi angaphandle noma indawo yokushisa ephezulu.

ABS resin Injection Molding IzinzuzoIzakhiwo 1.Good kagesi 2.Impact ukumelana 3.Excellent amakhemikhali ukumelana, ikakhulukazi amaningi acid nokhahlo, glycerine, ane-alikhali, ama-hydrocarbon amaningi futhi alcohol, usawoti wezinto 4.Ihlanganisa amandla, ukuqina nokuqina kokukodwa kwento 5.Ukuqina komthwalo 6. I-Lightweight 7.Processing solid dimensional and surface gloss are good, easy to paint, coloring, can also is sprayed metal, electroplating, welding and bonding and other secondary processing performance. 8. I-ABS ingenziwa ngemibala ehlukahlukene njengoba kudingeka. Uma engeza ilangabi cishe yizona ezisetshenziswa kabanzi okufakiwe noma i-anti-ultraviolet okufakiwe ku-ABS, ingasetshenziswa ukukhiqiza izingxenye zamadivayisi angaphandle noma indawo yokushisa ephezulu.

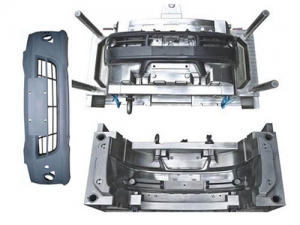

Ukusetshenziswa plastic ABS resinI-ABS inezinyathelo zayo ezinhlobonhlobo zezicelo ngenxa yokusebenza kwayo okuhle kakhulu nekhono lenqubo enhle. Okuqukethwe okuyinhloko kungokulandelayo: 1. Imboni Yezimoto Izingxenye eziningi embonini yezimoto zenziwe ngama-ABS noma ama-alloys e-ABS. Isibonelo: ideshibhodi yezimoto, iphaneli elingaphandle lomzimba, iphaneli yokuhlobisa ingaphakathi, isondo lokushayela, iphaneli yokufaka umsindo, ukukhiya umnyango, ubhampa, ipayipi lokungenisa umoya nezinye izinto eziningi i-ABS isetshenziswa kakhulu ekuhlobiseni kwangaphakathi kwezimoto, njengebhokisi legilavu kanye nomhlangano webhokisi yenziwe nge-ABS engamelana nokushisa, i-doorill izesekeli ezingenhla nezingezansi, imaski yethangi lamanzi eyenziwe nge-ABS, nezinye izingxenye eziningi ezenziwe nge-ABS njengezinto zokusetshenziswa. Inani lezingxenye ze-ABS ezisetshenziswa emotweni cishe liyi-10 kg. Phakathi kwezinye izimoto, inani lezingxenye ze-ABS ezisetshenzisiwe nalo liyamangaza impela. Izingxenye eziyinhloko zemoto zenziwe nge-ABS, njenge-dashboard ene-PC / ABS njengamathambo, kanti ingaphezulu lenziwe ngefilimu le-PVC / ABS / BOVC. 2. I-Electronic and Electrical Appliances ABS kulula ukujova egobolondweni nasezingxenyeni eziqondile ezinesimo esiyinkimbinkimbi, usayizi ozinzile nokubukeka okuhle. Ngakho-ke, i-ABS isetshenziswa kabanzi ezintweni zasendlini nasendlini encane, njengama-TV, amarekhodi, amafriji, amafriji, imishini yokuwasha, ama-air conditioner, ama-vacuum cleaner, imishini yefeksi yasekhaya, i-audio ne-VCD. I-ABS ibuye isetshenziswe kabanzi ekuhlanzeni i-vacuum futhi izingxenye ezenziwe yi-ABS nazo zisetshenziswa ezitsheni zasekhishini. Imikhiqizo yomjovo we-ABS ingaphezu kwe-88% yemikhiqizo eseplastiki ephelele yeziqandisi. 3. Izinsiza kusebenza zeHhovisi Ngoba i-ABS ine-gloss ephezulu nokubumba okulula, okokusebenza kwehhovisi nemishini kudinga ukubukeka okuhle nesibambo esihle, njengecala lefoni, ikesi lememori, ikhompyutha, umshini wefeksi kanye nomshini wokuphinda amakhophi, izingxenye ze-ABS zisetshenziswa kabanzi. Izinsiza ze-4.Industrial Ngoba i-ABS inokubumba okuhle, kunenzuzo yokwenza imishini chassis negobolondo ngosayizi omkhulu, ukusonteka okuncane nosayizi ozinzile. Njengokusebenza kwedeshibhodi, itafula elisebenzayo, ichibi elinamanzi, ibhokisi lezingxenye, njll.

Imikhiqizo nokwakhiwa kwesikhunta

1.Ukujiya kodonga kwemikhiqizo: Udonga lwemikhiqizo luhlobene nobude bokuncibilika kokuncibilika, ukusebenza kahle kokukhiqiza nezidingo zokusetshenziswa. Isilinganiso sobude bokugeleza obukhulu be-ABS sincibilika kusayizi wodonga lomkhiqizo cishe ngu-190: 1, ohluka ngokuya ngebanga. Ngakho-ke, ukushuba kodonga lwemikhiqizo ye-ABS akufanele kube mncane kakhulu. Ngemikhiqizo edinga ukwelashwa nge-electroplating, ubukhulu bodonga kufanele bube buthakathaka kancane ukukhulisa ukunamathela phakathi kokumboza nobuso bomkhiqizo. Ngalesi sizathu, ubukhulu bodonga lomkhiqizo kufanele bukhethwe phakathi kuka-1.5 no-4.5 mm. Lapho sicubungula ukushuba kodonga kwemikhiqizo, kufanele futhi sinake ukufana kobukhulu bodonga, hhayi umehluko omkhulu kakhulu. Ngemikhiqizo edinga ukufakwa i-electroplated, ingaphezulu kufanele libe yisicaba futhi lingashisi, ngoba lezi zingxenye kulula ukunamathela othulini ngenxa yomphumela we-electrostatic, okuholela ekuqineni okuncane kwengubo. Ngaphezu kwalokho, ubukhona bamakhona abukhali kufanele kugwenywe ukuvimbela ukugxila kwengcindezi. Ngakho-ke, kufanelekile ukuthi kudinge ushintsho lwe-arc kuma-engeli wokujika, amalunga wobukhulu nezinye izingxenye.

2. Umthambeka owonakalisayo: Umthambeka owonakalisayo wemikhiqizo uhlobene ngqo nokuncipha kwayo. Ngenxa yamamaki ahlukile, ubujamo obuhlukile bemikhiqizo nezimo ezahlukahlukene zokwakha, ukuncipha okwenziwe kunomehluko othile, ngokuvamile ku-0.3 0.6%, kwesinye isikhathi kuze kufike ku-0.4 0.8%. Ngakho-ke, ukunemba kobukhulu bokwakhiwa kwemikhiqizo kuphezulu. Ngemikhiqizo ye-ABS, imithambeka eyonakalisayo ibhekwa ngale ndlela elandelayo: ingxenye esemqoka ingama-degree angama-31 eceleni kwesiqondiso esonakalisayo, nengxenye yomgogodla ingu-1 degree 20'kanye nesiqondiso esonakalisayo. Kumikhiqizo enesimo esiyinkimbinkimbi noma enezinhlamvu namaphethini, ithambeka elidilikayo kufanele lenyuswe ngokufanele.

Izidingo zokukhishwa: ngoba ukuphela okubonakalayo komkhiqizo kunomthelela omkhulu ekusebenzeni kwe-electroplating, ukuvela kwanoma yiziphi izibazi ezincane kuzoba sobala ngemuva kokuqothulwa, ngakho-ke ngaphezu kwesidingo sokuthi azikho izibazi ezikhona emgodini wokufa, indawo esebenzayo yokukhishwa kufanele ibe nkulu, ukuvumelanisa kokusetshenziswa kwama-ejectors amaningi kunqubo yokukhipha kufanele kube kuhle, futhi amandla okukhipha kufanele afane.

4. Ukukhipha: Ukuze uvimbele ukukhipha okubi ngesikhathi senqubo yokugcwalisa, shisa ulayini ocibilikile nolusobala, kuyadingeka ukuvula indawo yokufaka umoya noma yokufaka umoya ngokujula okungaphansi kuka-0.04 mm ukwenza lula ukukhishwa kwegesi kusuka incibilike. 5. Umgijimi nesango: Ukuze wenze ukuncibilika kwe-ABS kugcwalise zonke izingxenye zomgodi ngokushesha okukhulu, umgijimi womgijimi akufanele abe ngaphansi kuka-5 mm, ubukhulu besango kufanele bube ngaphezu kuka-30% wobukhulu komkhiqizo, nobude bengxenye eqondile (kubhekiswa engxenyeni ezongena emgodini) kufanele kube cishe u-1 mm. Ukuma kwesango kufanele kunqunywe ngokuya ngemfuneko yomkhiqizo kanye nesiqondiso sokugeleza kwempahla. Umgwaqo awuvunyelwe ukuthi ubekhona endaweni yokumboza yemikhiqizo edinga ukufakelwa ugesi.

Ukwelashwa komhlaba nokuhlobisaI-ABS kulula ukuthi ipendwe futhi ifakwe imibala. Ingabuye ifuthwe ngensimbi nange-electroplating. Ngakho-ke, izingxenye ze-ABS zivame ukuhlotshiswa futhi zivikelwe ngokufaka umjovo wokujova umjovo nokufafaza, ukuphrinta usilika, ukuphrinta electroplating nokushaya okushisayo ebusweni bezingxenye zokubumba. 1. I-ABS inezici ezinhle zomjovo, futhi ingathola amamaki ahlukahlukene okusanhlamvu, inkungu, indawo ebushelelezi nesibuko ngasesifeni. 2. I-ABS inobumbano obuhle bepende, futhi kulula ukuthola indawo ehlukahlukene yombala ngokufafaza indawo. Futhi ukuphrinta kwesikrini izinhlamvu ezahlukahlukene namaphethini. 3. I-ABS inezici ezinhle zokufakwa kwe-electrochemical plating futhi ukuphela kwama-plastiki angathola indawo yensimbi kalula ngokufakwa kwe-electroless. Izindlela zokufaka i-electroless zifaka i-electroless plating plating, i-electroless nickel plating, i-electroless silver plating ne-electroless chromium plating.