Ukwenza isikhunta

Incazelo emfushane:

Ukwenza isikhunta (Ukwenza i-Die) kuyinqubo yokukhiqiza izinto ngokuya ngomdwebo wesikhunta, usebenzisa ukusika okwenziwe ngomshini, imishini yokuphamba, ukwelashwa kwendawo nokwelashwa kokushisa, futhi ekugcineni ukuhlanganisa zonke izingxenye zibe yisikhunta ngokusho komdwebo wokuklama.

Ukwenza isikhunta nokukhiqiza kuyimboni ebaluleke kakhulu embonini yokukhiqiza yanamuhla. Inikezela ngemishini yenqubo ebalulekile yezikhulu ezinkulu, ukusebenza kahle okuphezulu nokukhiqizwa kwezimboni ezisezingeni eliphakeme.

Siyini isikhunta?

Isikhunta (isikhunta, ukufa) saziwa ngokuthi "umama wemboni", okuyindlela ebalulekile yenqubo yokufeza ukucacisa okuphezulu, ukusebenza kahle okuphezulu nokukhiqizwa okukhulu embonini yezokwakha yanamuhla. Ekhiqizeni imboni yesikhunta, isikhunta namathuluzi ahlukahlukene asetshenziselwa ukuthola imikhiqizo edingekayo ngomjovo, ukubumba okushaywayo, ukukhishwa, isikhunta ekubunjweni noma ekwakheni, ukuncibilikisa, ukugxisha nezinye izindlela. Ngamafuphi, isikhunta siyithuluzi elisetshenziselwa ukwenza izinto zokubumba. Leli thuluzi lakhiwa izingxenye ezahlukahlukene, futhi isikhunta esihlukile sakhiwa izingxenye ezahlukahlukene. Ikakhulu iqaphela ukucutshungulwa kokuma kwento ngokuguqula isimo somzimba sokwakheka kwento. Kuyaziwa ngokuthi "umama wemboni".

Kuyini ukukhiqizwa kwesikhunta?

Cishe zonke izikhunta zenziwe ngensimbi, kanti ezingama-90% zazo zenziwe ngensimbi.

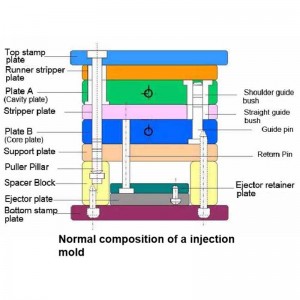

Ngaphansi kokusebenza kwamandla angaphandle, i-billet yensimbi iba ithuluzi lokukhiqiza elinomumo nosayizi othize. It is kabanzi stamping, isikhunta UKWAKHA, isihloko esibandayo, extrusion, powder okusansimbi izingxenye ngokucindezela, ingcindezi thusi, kanye nobunjiniyela amapulasitiki, iraba, izinto zobumba kanye neminye imikhiqizo yokuminyanisa noma umjovo udini. Isikhunta sinomugqa othize noma umumo wangaphakathi womgogodla, futhi okungenalutho kungahlukaniswa ngokuya ngesimo se-contour (blanking) ngokusebenzisa umumo we-contour onqenqemeni. Ukuma komgodi wangaphakathi kungasetshenziselwa ukuthola ukwakheka okulingana nhlangothi-ntathu kwe-billet. Isikhunta ngokuvamile sifaka izingxenye ezimbili: isikhunta esisusekayo nesikhunta esinqunyiwe (noma isibhakela nesikhunta se-concave), esingahlukaniswa futhi sihlanganiswe. Lapho izingxenye zihlukaniswa, izikhala zifakwa emgodini wesikhunta ukuze zakhe lapho zivaliwe. Isikhunta siyithuluzi eliqondile elinomumo oyinkimbinkimbi futhi elinamandla amakhulu e-billet. Inezidingo eziphakeme ngamandla esakhiwo, ukuqina, ukuqina kobuso, ukuqina kobuso nokusebenza ngokunemba kokusebenza. Izinga lokuthuthuka lokukhiqizwa kwesikhunta lingenye yamamaki abalulekile ezingeni lokukhiqizwa kwemishini.

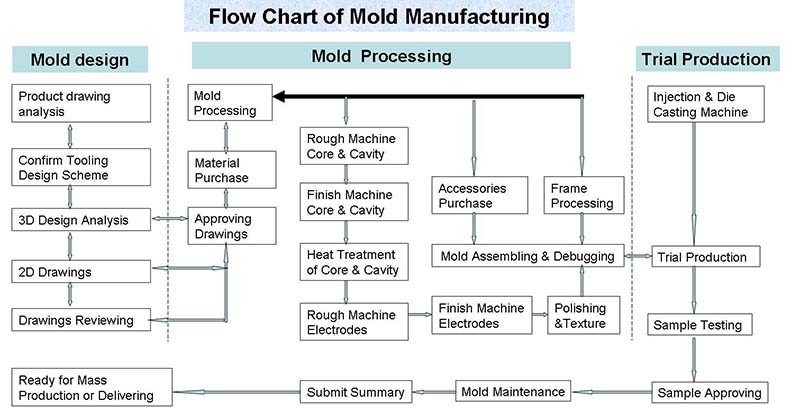

Inqubo yokwenziwa kwesikhunta ifaka phakathi: ukwakheka kwesikhunta, ukucubungula isikhunta, ukuhlolwa kwesikhunta nokuhlolwa kokuhlolwa, ukuguqulwa kwesikhunta nokulungiswa, nokugcinwa kwesikhunta.

Isikhunta yokukhiqiza ukucutshungulwa ngokuvamile waqaphela ngokusebenzisa UKWAKHA, ukuzisika, ukwelashwa ukushisa kanye inhlangano nezinye izinqubo. Ukuze kuqinisekiswe ikhwalithi yokukhiqiza yesikhunta futhi kunciphise izindleko zokukhiqiza, okokusebenza kufanele kube nokuthambeka okuhle, ukusika imishini, ukuqina nokugaya, futhi kufanele futhi kube ne-oxidation encane, ukuzwela kwe-decarbonization nokuzimaza ukuthambekela kokuqhekeka kokuqina. Ukuzisika kuthatha amaphesenti angama-70 omsebenzi wokucubungula isikhunta. Isinyathelo esibucayi kunazo zonke ukuthola umgodi ohlangabezana nezidingo zomumo, ubukhulu bokunemba nobukhulu bekhwalithi, kanye nazo zonke izindlela.

Inqubo yokwenza isikhunta

Insimbi engenalutho yokwenza isikhunta igoqiwe futhi yakhiwa esitshalweni sensimbi, kanti isitshalo sesikhunta singakhetha ngqo ukuthenga. Ukwenza isikhunta ukwenza lezi zikhala zensimbi zibe yizikhunta ezingakhiqiza imikhiqizo ekukhiqizweni. Ukwenziwa kwesikhunta kufaka phakathi ukwakheka kwesikhunta, ukusikwa kanye nokuhlangana komgogodla wesikhunta kanye nesisekelo sesikhunta

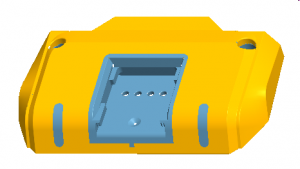

1. Ukwakhiwa kwesikhunta kuqedwa onjiniyela abangochwepheshe. Isikhunta design kuyinto ejwayelekile futhi isisekelo yonke ukukhiqizwa isikhunta. Ngokuya ngezidingo zesakhiwo somkhiqizo nokunemba kobuso ngamehlo, izikhathi zokufaka isicelo kanye nokukhipha okulindelekile, kanye nokumiswa komshini wokubumba umjovo, unjiniyela kufanele akhethe kahle insimbi engxenyeni ngayinye yesikhunta futhi anqume ukwakheka nenqubo yesikhunta. Ukuhleleka komklamo wesikhunta kunquma ubunzima bokukhiqiza, izindleko, impilo yesevisi, ukukhiqiza kanye nekhwalithi yomkhiqizo wesikhunta.

Isikhunta siwuhlobo lwemishini ebizayo. Ekuklanyeni, onjiniyela bethu basebenzisa isoftware ukuhlaziya nokulingisa ukusatshalaliswa kwezingxenye, indlela yokugeleza, iphuzu lokujova kanye nokwakheka kwezingxenye.

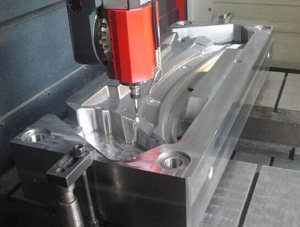

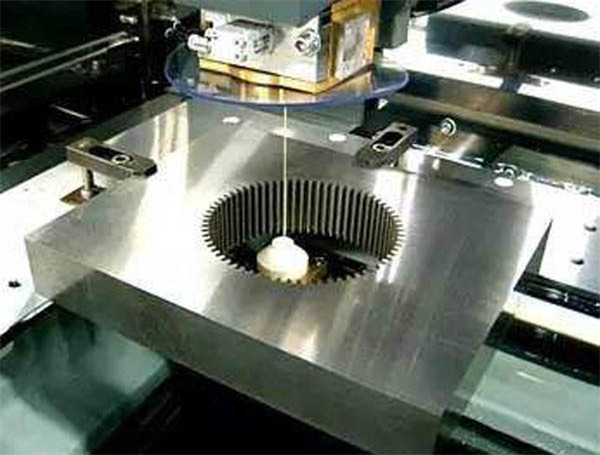

2. Machining isikhunta. Isikhunta billet sicutshungulwa ngethuluzi lomshini ngokuya ngokwakhiwa konjiniyela nemibhalo yenqubo. Ngokuvamile, amathuluzi womshini wokusika nemishini esetshenziselwa ukwenza isikhunta kufaka phakathi i-CNC, i-EDM, i-WEDM, i-lathe, i-grinder, umshini wokupholisha, njll. Amathuluzi omshini athuthukile futhi anembile angathuthukisa kakhulu ukunemba kwesikhunta, anciphise umjikelezo wokukhiqiza futhi anciphise izindleko. Izinhlobo ezahlukahlukene zesikhunta zisebenzisa inhlanganisela ehlukile yamathuluzi omshini: isikhunta somjovo kanye nesikhunta sokuphonsa esivamile sisebenzisa i-CNC, i-EDM ne-WEDM. Ukunyathela isikhunta kanye nesikhunta se-extrusion kuvame ukusebenzisa i-CNC ne-WEDM

3. Isikhunta inhlangano. Ukuhlangana kwesikhunta kuncike kochwepheshe. Kufaka phakathi i-die core, i-slide block, iposi yokuqondisa, indlela yokukhipha, ukufana phakathi kohlaka lokufa nemoto, umhlangano womgijimi oshisayo, kanye nengxenye engeke isikwe, nomhlangano wokugcina jikelele. Ukuphakama kokunemba kwemishini, kuncipha umthwalo womhlangano wokufa, kufushane umjikelezo wokukhiqiza futhi izindleko ziphansi. Ngemuva kokuphothulwa komhlangano wetefa, kuyadingeka ukuthi kuhlolwe, kuqinisekiswe, kulungiswe iphutha futhi kuthuthukiswe okufayo kuze kube yilapho ikwazi ukukhiqiza imikhiqizo efanelekile nezinye izinto eziningi.

Inqubo ejwayelekile yokwenza isikhunta

CNC machining

Imishini Yokuchithwa Kwe-EDM-Electrical

Ukusika i-WEDM-wire electrode

Ukulinganisa nokuhlanganisa isikhunta

Inkampani yakwaMestech ibandakanyeka kakhulu ekukhiqizeni isikhunta sepulasitiki nomjovo womkhiqizo, kanye nesikhunta sehadiwe (insimbi yokufa yensimbi, isitampu sokufa) yokukhiqiza nezingxenye zensimbi.