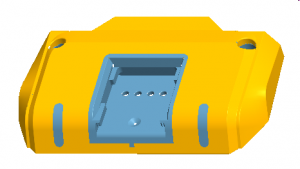

Hot umgijimi isikhunta

Incazelo emfushane:

Hot umgijimi isikhuntauhlobo lwesikhunta olusebenzisa idivaysi yokushisa ukugcina ukuncibilika kumgijimi kusuka ekuqiniseni sonke isikhathi. Ngoba ipulasitiki kumgijimi ihlale isesimeni esincibilikisiwe, futhi okokupholisa umlomo wombhobho akudingi ukuthi kukhishwe ngesikhathi sokubunjwa komjovo. Unomjikelezo omfushane wokwakha ukwedlula isikhunta sendabuko, futhi igcina izinto zokusetshenziswa ezingaphezulu, ngakho-ke isikhunta somgijimi esishisayo sisetshenziswe kabanzi emazweni athuthukile nasezifundeni zomhlaba.

Hot umgijimi isikhunta uhlobo isikhunta esebenzisa idivayisi Ukushisa ukugcina ukuncibilika umgijimi kusuka solidifying sonke isikhathi. Ngoba ipulasitiki kumgijimi ihlale isesimeni esincibilikisiwe, futhi okokupholisa umlomo wombhobho akudingi ukuthi kukhishwe ngesikhathi sokubunjwa komjovo. Unomjikelezo omfushane wokwakha ukwedlula isikhunta sendabuko, futhi igcina izinto zokusetshenziswa ezingaphezulu, ngakho-ke isikhunta somgijimi esishisayo sisetshenziswe kabanzi emazweni athuthukile nasezifundeni zomhlaba.

Hot umgijimi udini uhlelo isikhunta kuyinto ebalulekile ukwesekwa subsystem of umjovo isikhunta uhlelo. Kuqinisekisa ukuthi izinto zepulasitiki ezincibilikisiwe kumgijimi zigcinwa zishisa njalo isikhathi eside ngokushisa kagesi. Kuyindlela ebalulekile yokusiza ukukhiqiza izingxenye ezinkulu zobuso obukhulu, obunemizimba emincane, ezisezingeni eliphakeme ezikhiqizwa ngokusebenzisa umjovo wokubumba nokufeza ukukhiqizwa okusebenzayo.

Hot umgijimi umjovo isikhunta

Hot umgijimi uhlelo isikhunta

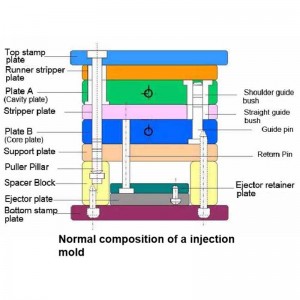

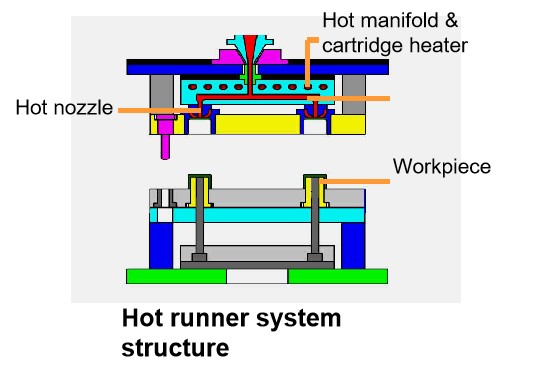

Isakhiwo sohlelo lomgijimi oshisayo

Hot umgijimi uhlelo ngokuvamile yakhiwa umlomo wombhobho hot, ezininginingi hot, lokushisa isilawuli kanye izesekeli. Kunezinhlobo ezimbili zemibhobho eshisayo: umlomo ovulekile ovulekile kanye ne-pin valve umlomo wombhobho oshisayo. Ngoba uhlobo lombhobho oshisayo lunquma ngqo ukukhethwa kohlelo lomgijimi oshisayo nokwenziwa kwesikhunta, uhlelo lomgijimi oshisayo luvame ukuhlukaniswa ngohlelo lomgijimi oshisayo ovulekile kanye nephini yohlelo lomgijimi oshisayo. Ipuleti lehlukanisi lisetshenziswa emgodini omningi noma ekuphakelweni kwamaphoyinti amaningi, ukuphakelwa kwephoyinti elilodwa, kodwa ileveli yempahla ebonakalayo. Okokusebenza kuvamise ukuba yi-P20 noma i-H13. Ipuleti lokuhlukanisa ngokuvamile lihlukaniswe ngezigaba ezimbili ezijwayelekile nezingajwayelekile. Isakhiwo saso sinqunywa ngokusatshalaliswa kwesikhala ekubunjweni, ukuhlelwa kombhobho kanye nokuma kwesango. Ibhokisi lokulawula ukushisa lifaka umphathi, ikhebuli, isixhumi kanye nezintambo izisekelo zesilisa nezinsikazi, njll. Izinsiza zomgijimi ezishisayo ngokuvamile zifaka: i-heater ne-thermocouple, indandatho yokufaka uphawu yomgijimi, isixhumi nebhokisi lokuhlangana, njll.

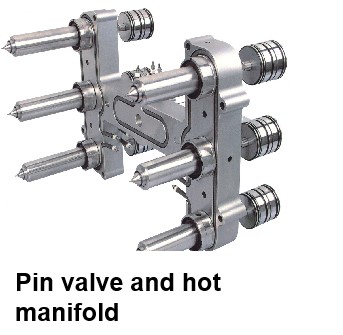

Izinhlobo zomgijimi oshisayo:

Kunezinhlobo ezimbili zabagijimi abashisayo: uhlelo oluvulekile lomgijimi oshisayo kanye nohlelo lwe-needle-valve runner run. Babizwa ngokusho kombhobho ovulekile oshisayo nomgijimi oshisayo wenaliti-valve ngokulandelana.

1). Vula uhlobo

Isikhunta somgijimi oshisayo esivulekile sinezinzuzo zesakhiwo esilula, ukukhawulelwa kwempahla ephezulu, ukudweba okulula kocingo nokuvuza kwentambo, ikhwalithi ephezulu yomhlaba, kanye nezicelo ezimbalwa ku-High Precision Mould phesheya. Isikhunta esifanayo singaxubaniswa namavalvu enaliti abakhiqizi abahlukene. Umgijimi oshisayo ovulekile angahlukaniswa abe izingxenye ezimbili: umgijimi oshisayo wechweba lamanzi kanye nomgijimi oshisayo wesango. Umgijimi oshisayo wesango lephoyinti, njengoba igama lisho, isango lesango lephoyinti lincane kakhulu, ngokuvamile izintambo ezingama-80 kuphela, umkhiqizo womkhiqizo ubushelelezi kakhulu, ulungele umjovo wokubumba imikhiqizo emincane. Isango elikhulu umgijimi oshisayo unesango elikhulu nomthamo omkhulu womjovo, ofanele umjovo wemikhiqizo emikhulu

2). Pin valve uhlobo

I-Pin valve uhlobo umgijimi oshisayo usindisa impahla, ubuso bezingxenye zepulasitiki buhle, ikhwalithi yangaphakathi ihlangene, namandla aphezulu. Kunabagijimi ababili abashisayo bezinaliti emhlabeni jikelele (ngokuya ngenqubo yomjovo): uhlobo lwesilinda nohlobo lwentwasahlobo.

Umehluko phakathi kohlobo lwentwasahlobo nohlobo lwesilinda ukuthi alukwazi ukulawula ukulandelana kwesikhathi futhi luxazulule inkinga yokulandela insimbi. Ububanzi obuncane bufaka imibhobho emelana namanzi, amaphayiphu entwasahlobo yamapayipi nemibhobho yangaphakathi yokushisa yathuthukiswa.

Usebenza kanjani umgijimi oshisayo?

Ngoba induku yokushisa nendandatho yokufudumeza iseduze noma maphakathi nomgijimi, umgijimi wonke osuka endaweni yokuvula umlomo wombhobho uya esangweni lomshini wokubumba umjovo usesimweni sokushisa okuphezulu, esigcina ipulasitiki kumgijimi incibilika isimo. Ngakho-ke, ubuchwepheshe obushisayo bomgijimi kwesinye isikhathi kuthiwa uhlelo lokucwilisa ipayipi lokushisa, noma ukubumba okungenamgijimi. Uhlelo lomgijimi oshisayo ngokuvamile luqukethe umbhobho oshisayo, umsabalalisi, ibhokisi lokulawula ukushisa nezinye izinsimbi.

Izici zomgijimi oshisayo

Ukusetshenziswa komgijimi oshisayo we-die system technology kuya ngokuya kuvuthwa ngokwengeziwe. It has izinzuzo eziningi, okhuthaza ukuthuthukiswa umjovo udini umkhakha. Kukhona nokushiyeka okufanele sikubheke esicelweni.

Inzuzo eshisayo umgijimi uhlelo isikhunta

A. Ilungele imikhiqizo emikhulu

Ngenxa yobukhulu obukhulu, ivolumu enkulu yomjovo nendawo enkulu yezingxenye, kunzima ukugcina amapulasitiki ejwayelekile ekubunjweni komjovo futhi agcwalise umgodi endaweni yokushisa encibilika kakhulu. Umjovo oshisayo wamaphuzu amaningi omgijimi kufanele usetshenziselwe ukuqinisekisa ukubunjwa okugcwele komjovo.

B. Ilungele izinto Ezinzima ukwakheka

I-viscosity ephezulu, i-viscosity ephansi, izinga lokushisa eliphakeme lokubumba. Uhlelo lomgijimi oshisayo lungaxazulula lezi zinkinga. Isibonelo: umjovo we-powder wensimbi, umjovo we-ceramic powder, umjovo wamagnetic epulasitiki, umjovo ophethe ipulasitiki, irabha ye-thermoplastic (TPE). C. Ukonga izindleko

Hot umgijimi umjovo, akukho umlomo wombhobho, akukho imfucuza umgijimi, ugcine eziningi izindleko impahla.

D. Yehlisa ingcindezi yomjovo, wonge amandla, uthuthukise umkhiqizo womshini wokubumba umjovo, unciphise ukugqoka kwesikhunta.

E. Ifanele ijubane lomjovo wejubane. Ijubane lomjovo wesivinini esiphezulu alithuthukisi kuphela ukusebenza kahle kokukhiqizwa kwemikhiqizo enezindonga ezincane njengezinkomishi neziqukathi.

F. Ukwenza ngcono ikhwalithi yomkhiqizo

Enqubeni yokwakha isikhunta somgijimi oshisayo, izinga lokushisa lokuncibilika kwepulasitiki lilawulwa ngokunembile ngohlelo lomgijimi oshisayo. Amapulasitiki angageleza ngokulinganayo emgodini ngamunye, okuholela ezingxenyeni zekhwalithi efanayo. Izingxenye zomgijimi ezishisayo zinekhwalithi enhle, ukucindezela okusele okusalile kanye nokuncipha okuncane ngemuva kokucekelwa phansi. Imikhiqizo eminingi esezingeni eliphakeme emakethe ikhiqizwa isikhunta somgijimi oshisayo. Izingxenye eziningi zepulasitiki kumafoni e-Motorola, amaphrinta we-HP nama-laptops akwa-Dell enziwa ngesikhunta somgijimi oshisayo.

G. Ukukhuthaza ukuzenzekelayo kokukhiqiza

Umkhiqizo oqediwe wakhiwa ngomgijimi oshisayo wesikhunta, asikho isidingo sokunquma isango, futhi umgijimi obandayo usetshenzisiwe kabusha. Kuyasiza ekukhiqizeni okuzenzakalelayo. Abakhiqizi abaningi bakwamanye amazwe bahlanganisa umgijimi oshisayo ne-automation, okuthuthukisa kakhulu ukusebenza kahle kokukhiqiza.

Ukwehluleka kwesikhunta sohlelo lomgijimi oshisayo

Uma kuqhathaniswa nesikhunta somgijimi obandayo, ukushiyeka kwesikhunta somgijimi oshisayo kufingqiwe kulezi zici ezilandelayo.

A. Izikhunta Izindleko Ezikhuphukayo izingxenye zomgijimi ezishisayo zibiza kakhulu, futhi izindleko zesikhunta somgijimi oshisayo zingakhuphuka kakhulu. Uma okukhipha ingxenye kukuncane futhi isilinganiso sezindleko zesikhunta siphezulu, akuyona imali.

Izidingo zemishini ephezulu Isikhunta somgijimi oshisayo sidingeka ukuba senziwe ngomshini ngokunembile. Ukuhlanganiswa nokuhlanganiswa kohlelo lomgijimi oshisayo nesikhunta kuqinile kakhulu, ngaphandle kwalokho kuzoba nezinkinga eziningi ezinzima enqubeni yokukhiqiza isikhunta.

Ukusebenza nokunakekelwa okuyinkimbinkimbi

Uma kuqhathaniswa nesikhunta somgijimi obandayo, ukusebenza komgijimi oshisayo nokugcinwa kuyinkimbinkimbi. Uma zisetshenziswe ngendlela engafanele, izingxenye zomgijimi ezishisayo kulula ukuzilimaza futhi azikwazi ukukhiqizwa, okuholela ekulahlekelweni okukhulu kwezomnotho.

Ngokuvamile, isikhunta somgijimi oshisayo siye sasetshenziswa kabanzi ngenxa yokusebenza kwabo kahle kanye nemikhiqizo esezingeni eliphakeme, ngokuthuthukiswa kobuchwepheshe bokucubungula isikhunta nobuchwepheshe bemishini yokujova.

Ukusebenza komgijimi oshisayo ongumbumba

1. Ezingxenyeni ezinkulu zosayizi

Ezingxenyeni ezinobukhulu bazo obude obungaphezu kwama-300 mm, ivolumu nendawo yomjovo wepulasitiki kukhulu ngenxa yosayizi omkhulu. Uma ipulasitiki elicibilikile lipholile ngokushesha okukhulu, ukugcwaliswa komgodi akwanele, okuholela ekushodeni kweglue kanye ne-concave. Ukucwilisa nomugqa we-fusion osobala, noma umehluko wezinga lokushisa mkhulu kakhulu ukuthi ungadala ukuncipha noma ukusonteka kwezingxenye. Ngakho-ke, ukwengeza umgijimi oshisayo kuzoqinisekisa ukuthi opulasitiki bamanzi abajojowe bagcina ukushisa okungapheli isikhathi eside, futhi kuqinisekise ukuthi ukuncibilika kungagcwaliswa ngokushesha nangokugcwele. I-Cavity, futhi ikhiphe ngokushesha ukucindezeleka, thola imikhiqizo efanelekayo. Le mikhiqizo ifaka phakathi: ibhokisi lesilondolozi sepulasitiki, ibhokisi lenzuzo, ibhokisi lepulasitiki, ideshibhodi yezimoto, ibhampa, njll.

2. Ezingxenyeni ezibiyelwe ezincane

Ezingxenyeni ezibiyelwe ngogqinsi ezinobukhulu obungaphansi kuka-1.0 mm, ukushabalalisa ukushisa kuyashesha futhi ukupholisa kuyashesha, ukuncibilika akulula ukugcwalisa, noma kulula kakhulu ukukhiqiza ama-airmark kanye ne-deformation enkulu. Ijubane lokugcwalisa lokunamathisela kwe-melt lingakhuphuka ngokusebenzisa umgijimi oshisayo, ozuzisa ijubane lokugcwalisa lokunamathisela kwe-melt. Izingxenye zakheke ngokuphelele. Le mikhiqizo ifaka igobolondo lomakhalekhukhwini, iphaneli, njll. Uma isikhunta somgijimi oshisayo sihlanganiswa nomshini wokujova onejubane (umshini wokujova onawo wonke amandla kagesi), ubukhulu bezingxenye obuncane kakhulu bungaba ngu-0.30 mm kuye ku-0.50 mm.

3. Isetshenziselwa izingxenye zokubukeka ezisezingeni eliphakeme: umthunzi wesibani, ubuhlalu besibani,

Izingxenye zangaphandle zekhwalithi ephezulu ezifana nezibani zamalambu ezimoto nobuhlalu be-LED zidinga ukubonakala okuphezulu kokukhanya futhi azikwazi ukuba nokukhubazeka ngombala naku-airprint; ithuluzi elikhanyayo elisobala, kanye nesibuko semishini yasendlini; usayizi omkhulu Isembozo sangaphandle semishini kagesi kufanele sihlonyiswe ngamaphoyinti okuncoma i-glue ebusweni bezingxenye, kepha azikho izibazi zokuncelisa i-glue ezivunyelwe.

4. Isetshenziselwa izingxenye eziyinkimbinkimbi zesakhiwo

Lolu hlobo lomkhiqizo ikakhulukazi ngenxa yesidingo somkhiqizo, kunezinyathelo nezimbambo eziningi ngaphakathi, futhi umzila wokugeleza wokuncibilika ubhangisiwe, uyinkimbinkimbi futhi kunzima ukuwugcwalisa. Kunezinhlobo eziningi zamalambu wesibani.

5. Ngezingxenye ezinamanzi ampofu

Ukuze sithuthukise futhi sithuthukise izakhiwo zepulasitiki, sizofaka i-fiber fiber, i-flame retardant, i-powder yensimbi, i-carbon powder kanye nezithasiselo ze-anti-ultraviolet kuma-plastiki. Lokhu kungathuthukisa ukuqina kobukhulu kanye nokuhlanganiswa kwezingxenye, nezakhiwo zemishini, ukumelana nomlilo, izakhiwo zikagesi nokumelana nokuguga. Isibonelo, isetshenziselwa ibhokisi lokuhlangana elingaphandle, igobolondo lomkhiqizo wokuxhumana, igobolondo lokwenza izinto zasendlini kanye nezingxenye.

6. Ngezingxenye ezinkulu zamaqoqo

Ukulawulwa kwezindleko zezingxenye ezinkulu zamaqoqo kubaluleke kakhulu. Ukuze unciphise isikhathi sokujova umjovo futhi uvikele izindleko ezilethwe ingxenye yombhobho, kusetshenziswa isikhunta somgijimi oshisayo.

Inkampani yakwaMestech igxile ezingxenyeni ezahlukahlukene zepulasitiki zokukhiqizwa kwesikhunta nokukhiqizwa komjovo. Siqongelele ulwazi olucebile ekukhiqizeni i-lampshade ebonakalayo, igobolondo elikhulu lepulasitiki nesikhunta somgijimi oshisayo wokufaka umjovo womjovo omningi. Silangazelela ithuba lokubambisana nokukusiza kule ndawo. Sicela uxhumane nathi.

Izici zomgijimi oshisayo Ukusetshenziswa komgijimi oshisayo we-die system technology kuya ngokuya kuvuthwa ngokwengeziwe. It has izinzuzo eziningi, okhuthaza ukuthuthukiswa umjovo udini umkhakha. Kukhona nokushiyeka okufanele sikubheke esicelweni. Inzuzo eshisayo umgijimi uhlelo isikhunta

A. Ilungele imikhiqizo emikhulu Ngenxa yobukhulu obukhulu, ivolumu enkulu yomjovo nendawo enkulu yezingxenye, kunzima ukugcina amapulasitiki ejwayelekile ekubunjweni komjovo futhi agcwalise umgodi endaweni yokushisa encibilika kakhulu. Umjovo oshisayo wamaphuzu amaningi omgijimi kufanele usetshenziselwe ukuqinisekisa ukubunjwa okugcwele komjovo.

B. Ilungele izinto ezinzima ukwenza ifomu I-High viscosity, i-Viscosity ephansi, i-High Molding Temperature. Uhlelo lomgijimi oshisayo lungaxazulula lezi zinkinga. Isibonelo: umjovo we-powder wensimbi, umjovo we-ceramic powder, umjovo wamagnetic epulasitiki, umjovo ophethe ipulasitiki, irabha ye-thermoplastic (TPE).

C. Ukonga izindleko Umjovo womgijimi oshisayo, umlomo wombhobho, imfucuza yomgijimi, wonga izindleko eziningi ezibonakalayo.

D. Yehlisa ingcindezi yomjovo, wonge amandla, uthuthukise umkhiqizo womshini wokubumba umjovo, unciphise ukugqoka kwesikhunta.

E. Ifanele ijubane lomjovo wejubane. Ijubane lomjovo wesivinini esiphezulu alithuthukisi kuphela ukusebenza kahle kokukhiqizwa kwemikhiqizo enezindonga ezincane njengezinkomishi neziqukathi.

F. Ukwenza ngcono ikhwalithi yomkhiqizo Enqubeni yokwakha isikhunta somgijimi oshisayo, izinga lokushisa lokuncibilika kwepulasitiki lilawulwa ngokunembile ngohlelo lomgijimi oshisayo. Amapulasitiki angageleza ngokulinganayo emgodini ngamunye, okuholela ezingxenyeni zekhwalithi efanayo. Izingxenye zomgijimi ezishisayo zinekhwalithi enhle, ukucindezela okusele okusalile kanye nokuncipha okuncane ngemuva kokucekelwa phansi. Imikhiqizo eminingi esezingeni eliphakeme emakethe ikhiqizwa isikhunta somgijimi oshisayo. Izingxenye eziningi zepulasitiki kumafoni e-Motorola, amaphrinta we-HP nama-laptops akwa-Dell enziwa ngesikhunta somgijimi oshisayo.

G. Ukukhuthaza ukuzenzekelayo kokukhiqiza Umkhiqizo oqediwe wakhiwa isikhunta somgijimi oshisayo, asikho isidingo sokunquma isango, futhi umgijimi obandayo uphinde wenziwe kabusha. Kuyasiza ekukhiqizeni okuzenzakalelayo. Abakhiqizi abaningi bakwamanye amazwe bahlanganisa umgijimi oshisayo ne-automation, okuthuthukisa kakhulu ukusebenza kahle kokukhiqiza.

Ukwehluleka kwesikhunta sohlelo lomgijimi oshisayo Uma kuqhathaniswa nesikhunta somgijimi obandayo, ukushiyeka kwesikhunta somgijimi oshisayo kufingqiwe kulezi zici ezilandelayo.

A. Izikhunta Izindleko Ezikhuphukayo izingxenye zomgijimi ezishisayo zibiza kakhulu, futhi izindleko zesikhunta somgijimi oshisayo zingakhuphuka kakhulu. Uma okukhipha ingxenye kukuncane futhi isilinganiso sezindleko zesikhunta siphezulu, akuyona imali.

Izidingo zemishini ephezulu Isikhunta somgijimi oshisayo sidingeka ukuba senziwe ngomshini ngokunembile. Ukuhlanganiswa nokuhlanganiswa kohlelo lomgijimi oshisayo nesikhunta kuqinile kakhulu, ngaphandle kwalokho kuzoba nezinkinga eziningi ezinzima enqubeni yokukhiqiza isikhunta.

Ukusebenza nokunakekelwa okuyinkimbinkimbi Kuqhathaniswa nesikhunta somgijimi obandayo, ukusebenza kwesikhunta somgijimi oshisayo nokunakekelwa kuyinkimbinkimbi. Uma zisetshenziswe ngendlela engafanele, izingxenye zomgijimi ezishisayo kulula ukuzilimaza futhi azikwazi ukukhiqizwa, okuholela ekulahlekelweni okukhulu kwezomnotho.

Ngokuvamile, isikhunta somgijimi oshisayo siye sasetshenziswa kabanzi ngenxa yokusebenza kwabo kahle kanye nemikhiqizo esezingeni eliphakeme, ngokuthuthukiswa kobuchwepheshe bokucubungula isikhunta nobuchwepheshe bemishini yokujova.

Ukusetshenziswa umgijimi ashisayo udini 1). Ezingxenyeni ezinkulu zosayizi Ezingxenyeni ezinobukhulu bazo bungaphezu kwama-300 mm, ivolumu nendawo yomjovo wepulasitiki zinkulu ngenxa yosayizi omkhulu. Uma ipulasitiki elicibilikile lipholile ngokushesha okukhulu, ukugcwaliswa komgodi akwanele, okuholela ekushodeni kweglue kanye ne-concave. Ukucwilisa nomugqa we-fusion osobala, noma umehluko wezinga lokushisa mkhulu kakhulu ukuthi ungadala ukuncipha noma ukusonteka kwezingxenye. Ngakho-ke, ukwengeza umgijimi oshisayo kuzoqinisekisa ukuthi opulasitiki bamanzi abajojowe bagcina ukushisa okungapheli isikhathi eside, futhi kuqinisekise ukuthi ukuncibilika kungagcwaliswa ngokushesha nangokugcwele. I-Cavity, futhi ikhiphe ngokushesha ukucindezeleka, thola imikhiqizo efanelekayo. Le mikhiqizo ifaka phakathi: ibhokisi lesilondolozi sepulasitiki, ibhokisi lenzuzo, iphalethi lepulasitiki, ideshibhodi yezimoto, ibhampa, njll. 2). Ezingxenyeni ezibiyelwe ngezingxenyana Ezincanyana ezibiyelwe ngobukhulu obungaphansi kuka-1.0 mm, ukushabalalisa ukushisa kuyashesha futhi ukupholisa kuyashesha, ukuncibilika akulula ukugcwalisa, noma kulula kakhulu ukukhiqiza ama-airmark kanye ne-deformation enkulu. Ijubane lokugcwalisa lokunamathisela kwe-melt lingakhuphuka ngokusebenzisa umgijimi oshisayo, ozuzisa ijubane lokugcwalisa lokunamathisela kwe-melt. Izingxenye zakheke ngokuphelele. Le mikhiqizo ifaka igobolondo lomakhalekhukhwini, iphaneli, njll. Uma isikhunta somgijimi oshisayo sihlanganiswa nomshini wokujova onejubane (umshini wokujova onawo wonke amandla kagesi), ubukhulu bezingxenye obuncane kakhulu bungaba ngu-0.30 mm kuye ku-0.50 mm. 3). Isetshenziselwa izingxenye zokubukeka ezisezingeni eliphakeme: umthunzi wesibani, ubuhlalu bezibani, izingxenye zangaphandle ezisezingeni eliphakeme ezifana nezibani zamalambu ezimoto kanye nobuhlalu be-LED zidinga ukubonakala okuphezulu kokukhanya futhi azikwazi ukuba nokukhubazeka ngombala ne-airprint; ithuluzi elikhanyayo elisobala, kanye nesibuko semishini yasendlini; usayizi omkhulu Isembozo sangaphandle semishini kagesi kufanele sihlonyiswe ngamaphoyinti okuncoma i-glue ebusweni bezingxenye, kepha azikho izibazi zokuncelisa i-glue ezivunyelwe. 4). Isetshenziselwa izingxenye eziyinkimbinkimbi zokwakheka Lolu hlobo lomkhiqizo ikakhulu ngenxa yesidingo somkhiqizo, kunezinyathelo nezimbambo eziningi ngaphakathi, futhi umzila wokugeleza wokuncibilika ubhangisiwe, uyinkimbinkimbi futhi kunzima ukugcwalisa. Kunezinhlobo eziningi zamalambu wesibani. 5). Ezingxenyeni ezinamanzi ampofu Ukuze senze ngcono futhi sithuthukise izakhiwo zepulasitiki, sizofaka ingilazi yefayibha, ilangabi eligciniwe, i-powder yensimbi, i-carbon powder kanye nezithasiselo ze-anti-ultraviolet kuma-plastiki. Lokhu kungathuthukisa ukuqina kobukhulu kanye nokuhlanganiswa kwezingxenye, nezakhiwo zemishini, ukumelana nomlilo, izakhiwo zikagesi nokumelana nokuguga. Isibonelo, isetshenziselwa ibhokisi lokuhlangana elingaphandle, igobolondo lomkhiqizo wokuxhumana, igobolondo lokwenza izinto zasendlini kanye nezingxenye. 6). Ezingxenyeni ezinkulu zeqoqwana Ukulawulwa kwezindleko kwezingxenye ezinkulu zamaqoqo kubaluleke kakhulu. Ukuze unciphise isikhathi sokujova umjovo futhi uvikele izindleko ezilethwe ingxenye yombhobho, kusetshenziswa isikhunta somgijimi oshisayo.

Inkampani yakwaMestech igxile ezingxenyeni ezahlukahlukene zepulasitiki zokukhiqizwa kwesikhunta nokukhiqizwa komjovo. Siqongelele ulwazi olucebile ekukhiqizeni i-lampshade ebonakalayo, igobolondo elikhulu lepulasitiki nesikhunta somgijimi oshisayo wokufaka umjovo womjovo omningi. Silangazelela ithuba lokubambisana nokukusiza kule ndawo. Sicela uxhumane nathi.