Metal wokushaya

Incazelo emfushane:

Ukunyathela insimbi ukusebenzisa i-punch nokufa ukukhubazeka noma ukuphuka insimbi engenasici, i-iron, i-aluminium, ithusi namanye amapuleti nezinto zokwenziwa kwamanye amazwe ukufeza ukwakheka nosayizi wenqubo ethile.

Inqubo wokushaya angahlukaniswa inqubo ngokwahlukana futhi inqubo ukwakha (kuhlanganise eguqa, umdwebo kanye ukwakha). Inqubo yokwehlukanisa ukwehlukanisa ingxenye yokugxivizwa kanye nokungenalutho eceleni kolayini othile wentambo kwinqubo yokugxiviza, futhi ikhwalithi yengxenye ehlukanisiwe yengxenye yokugxotshwa kufanele ihlangabezane nezidingo ezithile; inqubo yokwakha ukwenza isitembu seplastiki esingenalutho singenalutho ngaphansi kwesimo sokungalimazi, futhi siguqule sibe sesimweni somkhiqizo esidingekayo, futhi sihlangabezane nezidingo zokubekezelelana okukodwa nezinye izici.

* Ngokuya ngezimo zokushisa okunyathela, kunezindlela ezimbili zokugwaza ezibandayo nezokushisa okushisayo. Lokhu kuncike emandleni, kupulasitiki, ukujiya, idiploma degree kanye namandla emishini, futhi nesimo sokuqala sokwelashwa kokushisa nesimo sokugcina senkonzo kufanele sicatshangelwe. 1. Cold nginyathela ukucutshungulwa kwensimbi ekamelweni lokushisa, ngokuvamile kusebenza ukushuba engaphansi kuka 4mm blank. Inezinzuzo zokungashisi, akukho sikhumba se-oxide, ikhwalithi enhle yendawo, ukusebenza okulula nezindleko eziphansi. Okubi ukuthi kunomsebenzi wokwenza umsebenzi ube lukhuni, okwenza insimbi ilahlekelwe yikhono lokuqhubeka nokuqina. Ubukhulu bokungenalutho bufane futhi akudingeki ukuthi kuklwebheke. 2. Ukushisa okushisayo insimbi kufudunyezwa ebangeni elithile lokushisa. Izinzuzo ukuthi ingaqeda ukucindezeleka kwangaphakathi, igweme ukuqina komsebenzi, inyuse uplastikhi wezinto ezibonakalayo, inciphise ukumelana ne-deformation futhi yehlise ukusetshenziswa kwamandla kwemishini

* Imikhiqizo yokushaya isitampu

* Izakhi ezintathu eziyisisekelo zohlelo lokukhiqiza lokunyathela: kufa, cindezela kanye nensimbi yensimbi

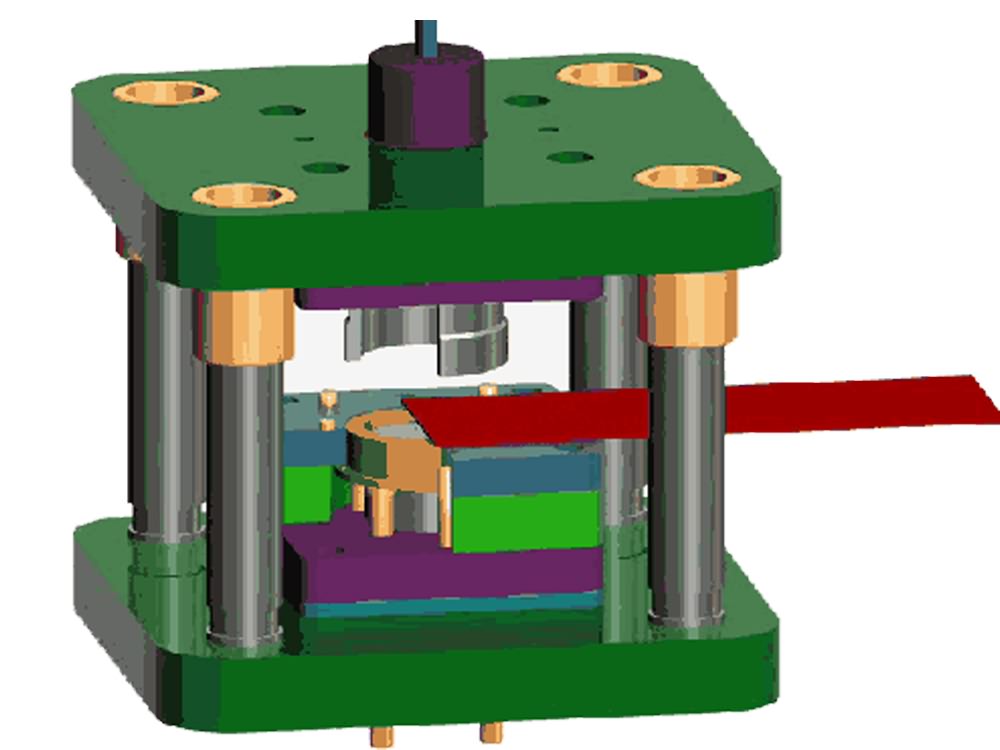

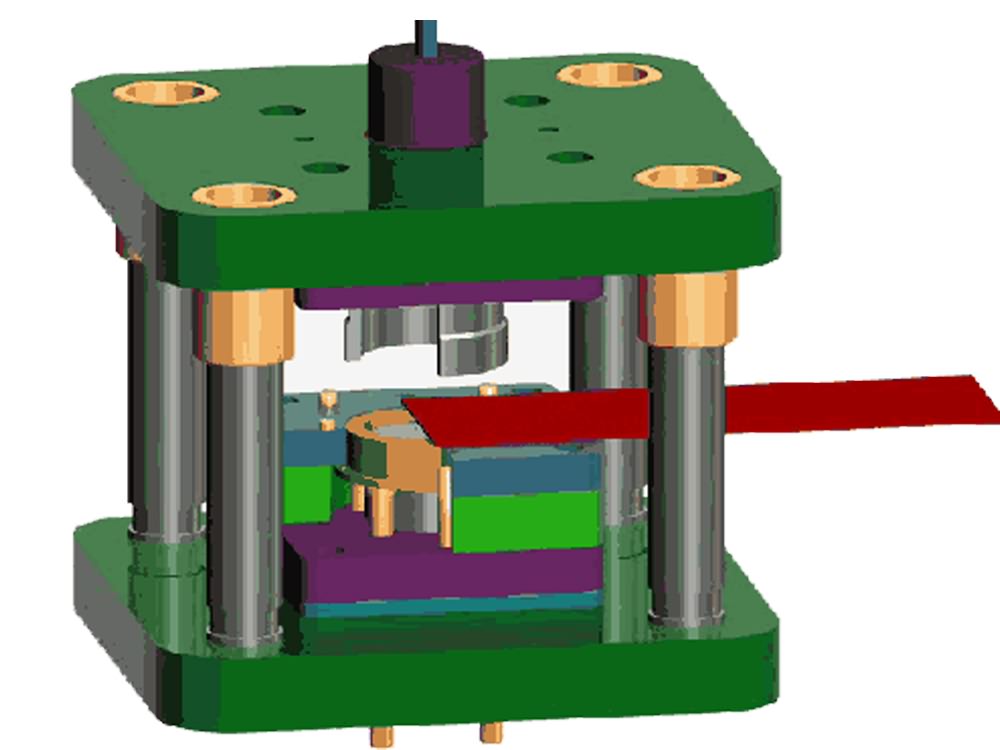

1. Ukushaya i-Die Die kungukufa okubalulekile ekukhiqizeni isitampu. Kunezinhlobo ezintathu ze-stamping die: die elula, die eqhubekayo kanye ne-compound die.

IDie Die iyi-die ebalulekile ekukhiqizeni isitampu. Kunezinhlobo ezintathu ze-stamping die: die elula, die eqhubekayo kanye ne-compound die.

(1) Ukufa okulula: ukufa okulula kungukufa okuqeda inqubo eyodwa kuphela ekushayweni okukodwa komshini. Kufanelekile ukukhiqizwa kweqoqo elincane lezingxenye zomumo ezilula.

(2) Ukuqhubeka okuqhubekayo: ngohlangothi olulodwa lomshini, i-die eliqedela izinqubo eziningana zokushaya izitho ezingxenyeni ezahlukahlukene zedayi ngasikhathi sinye libizwa ngokuthi yi-die eqhubekayo. Die okuqhubekayo kufanelekile kahle eliphezulu ukukhiqizwa okuzenzakalelayo.

(3) I-compound die: ngohlangothi, engxenyeni efanayo yediski yokuqedela izinqubo ezimbalwa zokugaya ngasikhathi sinye, ezaziwa ngokuthi i-composite die. Compound die ilungele nginyathela izingxenye nge okukhipha enkulu futhi ngokunemba high.

2. Umshini wokushaya

Ukukhiqizwa kokunyathela ikakhulukazi kwepuleti. Ngokusebenzisa isikhunta, angenza ukungabi nalutho, ukushaya isibhakela, ukwakha, ukudweba, ukuqedela, ukulala okungenalutho, ukubumba, ukuhlanganisa kanye nezingxenye ze-extrusion, njll, ezisetshenziswa kakhulu emikhakheni ehlukahlukene. Isibonelo, sisebenzisa amaswishi, amasokhethi, izinkomishi, amakhabethe, izitsha, amakesi wekhompyutha, ngisho nezindiza zemicibisholo Kunezinsiza eziningi ezingakhiqizwa ngesibhakela ngesikhunta. Kunezinhlobo eziningi zemishini yokubhoboza.

(1) Amandla wokucindezela amandla we-mechanical punch ye-Mechanical ine-stroke engaguquki, isivinini esishintshekayo nokukhiqiza okuphansi. Isivinini esikhulu 180 times / min.

(2) umfutholuketshezi cindezela

I-punch ye-hydraulic ingalungisa ukushaya okunyathela nge-valve ye-hydraulic ukuthuthukisa umkhiqizo. Ijubane eliphakeme kakhulu lingafinyelela izikhathi eziyi-1000 / iminithi. Okubi ukusetshenziswa kwamandla amakhulu, izidingo eziphezulu emvelweni kanye nomsebenzi osindayo wesondlo.

(3) Izinombolo zokulawula i-turret punch press

Usebenzisa i-servo motor ukushayela ikhanda, umkhiqizo uphakeme, ufike ezikhathini ezingama-800 / min. Ukusetshenziswa kwamandla amancane, ukugcinwa okulula nosayizi omncane. Ngakho-ke, isetshenziswe ngenkuthalo.

Ekugxivinyweni kwensimbi okujwayelekile, iningi lazo lisebenzisa isibhakela semishini. Ngokwoketshezi oluhlukile olusetshenziswa emishinini ye-hydraulic, kunemishini ye-hydraulic kanye ne-hydraulic press. Iningi lazo lisebenzisa imishini ye-hydraulic, kuyilapho imishini ye-hydraulic isetshenziselwa kakhulu imishini emikhulu noma ekhethekile. Ngenxa yezinzuzo zayo ezivelele, i-servo motor punch isetshenziswa kakhulu futhi kabanzi.

Izinto 3.Stamping Izinto nginyathela izingxenye ngokuvamile ipuleti. Izinto ezikhethelwe ukwakhiwa komkhiqizo zizohlangabezana nokusebenza kwensiza yomkhiqizo, njengokuqina, amandla nokusebenza komkhiqizo. Ngakolunye uhlangothi, kufanele ihlangabezane nezidingo zepulasitiki, ikhwalithi ebusweni nokuqina kwenqubo yokushaya isitampu. Idizayini yokwakheka kwezingxenye zokunyathela kufanele icubungule ngokugcwele izici zenqubo yokugaya, i-radius eguqa, imbobo yokuma, ukuhleleka, ukujula kokudweba, njll. Amapuleti asetshenziswa kakhulu ayinsimbi yensimbi ephansi, insimbi engagqwali, i-aluminium, ithusi kanye nama-alloys awo, anepulasitiki ephezulu futhi ukumelana ne-deformation ephansi, futhi kufanelekile ukunyathela okubandayo. (1). Izinsimbi eziyinsimbi: SPCC / SPCD / spce, SECC / SECD / sece, SGCC, sgld, Sus (2). Ingxubevange ye-Aluminium: al1050p, al1100p, al5020 (3). Ingxubevange yethusi: Pb phosphor bronze, HBS amandla aphezulu ethusi (4). Ingxubevange ye-Cupro nickel.

* Ubuchwepheshe bokwelashwa kobuso bezingxenye zokunyathela Ngemuva kokuthi insimbi icutshungulwe futhi yakhiwa ekuqaleni, idinga ukuguqula ingaphezulu lensimbi, yenze ubuhle bube ngaphezulu, futhi iqhubeke nokuguqula izakhiwo zemishini nezomzimba zamakhemikhali ezingaphezulu kwensimbi. Le nqubo ibizwa ngokuthi ukwelashwa komhlaba ngensimbi. Inhloso yokwelashwa kwendawo yensimbi ihlukaniswe izigaba ezine:

(1) Enhle

(2) Ukuvikelwa

(3) Izakhiwo ezikhethekile zomhlaba

(4) Thuthukisa izakhiwo zemishini, njengokuqina kokugqoka, i-lubricity, njll.

* Uhlobo lokwelashwa kwendawo i-Electroplating (i-zinc, ithusi, i-nickel, i-chromium, igolide, isiliva), ukufafaza nge-electrostatic, ukupenda kwesifutho, i-electrophoresis, ukuphrinta kwesikrini sikasilika, i-anodizing, i-blackening, i-passivation

* Ishidi lokunyathela ishidi kulula ukufeza ukukhiqizwa okuphezulu kokusebenza ngokusebenzisa imishini nokwenza i-automation kube lula ukuqaphela ukusetshenziswa kwemishini nokusebenza okuzenzakalelayo ngokusebenza kahle kokukhiqiza; izingxenye zokunyathela zinosayizi onembile nokushintshana okuhle; ubuso bushelelezi futhi bushelelezi, imvamisa ngaphandle kwemishini. Isetshenziswa kabanzi ezimotweni, okokusebenza kagesi, ithuluzi, ezokundiza nezinye izimboni zokukhiqiza.

IMestech ikunikeza ngemikhiqizo nezinsimbi zensimbi. Uma unesidingo noma udinga ukwazi okwengeziwe, sicela uxhumane nathi.