Idizayini yensimbi

Incazelo emfushane:

Izingxenye zensimbi design zifaka phakathi ukwakheka kwesakhiwo, ubukhulu, ukunemba kwendawo kanye nezakhiwo eziphelele zomshini, futhi ekugcineni kuphume imidwebo engxenyeni yokugcina yokukhiqiza.

Izingxenye zensimbi zisetshenziswa kabanzi ezimbonini ezahlukahlukene. Ukwakhiwa kwezingxenye zensimbi kungumthombo wezinto zokuphila zensimbi. IMestech ihlinzeka ngazo zonke izinhlobo zokucutshungulwa kwezingxenye zensimbi, ukucubungula kwemishini nokulungiswa kwemishini yokuxhumana, imishini yamandla omoya, imishini yezokwelapha nemishini ye-elekthronikhi.

Izakhiwo zomzimba nezamakhemikhali, ubukhulu, ukwakheka, imvelo yokusebenzisa kanye nokusetshenziswa kwezingxenye zensimbi ezahlukahlukene konke kuhlanganisiwe futhi kuhlukahlukene, futhi ubuchwepheshe babo bokucubungula bukhulu kakhulu.

Ukwenza umsebenzi omuhle ekwakhiweni kwezingxenye zensimbi, kunezinto ezintathu ezibalulekile okumele sizicacise.

Imvelo yokusetshenziswa kwezingxenye nezidingo zezingxenye

(1). Izidingo zosayizi

(2). Izidingo zobulukhuni

(3). Surface ngokunemba

(4). Izidingo zokulwa nokugqwala

(5). Izidingo zamandla

(6). Izidingo zokuqina

(7). Izidingo zokuqhuba ngogesi nezishisayo

(8). Izidingo zesisindo

(9). Izidingo ze-Ductility

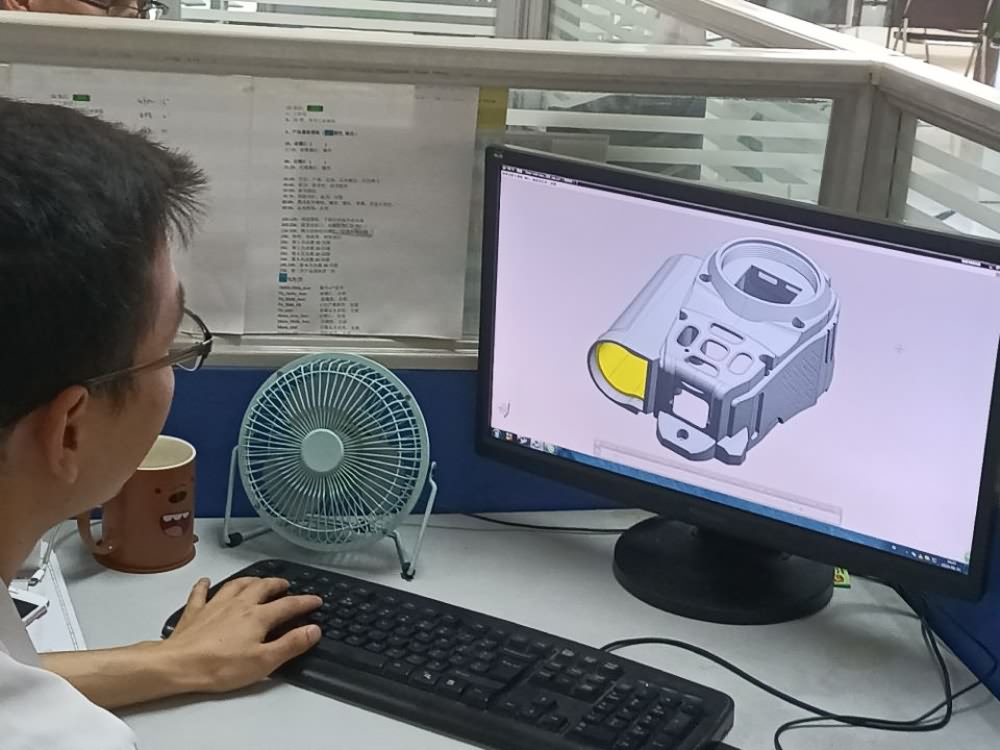

Unjiniyela uyaklama

2. Khetha izinto ezifanele ngokufanele

Izimiso zokukhetha izinto zokwakha izingxenye zensimbi zimi kanje:

(1). ukuhlangabezana nokusebenza kokusetshenziswa: impahla kufanele ikwazi ukuhlangabezana nezidingo zokuklama zamandla, ukuqina, ubulukhuni, ukuqhuba nezinye izinkomba.

(2) Ukusebenza okuhle kokucubungula: kulula ukucubungula nokukhiqizwa okuzinzile, ukuqinisekisa izinga eliphakeme lokuphasa, nokuhlangabezana nezidingo zokuklanywa kokunemba okukodwa nokusebenza kwezidingo.

(3) Umnotho: ungabona ukukhiqizwa okukhulu ngezindleko eziphansi.

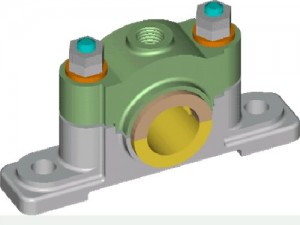

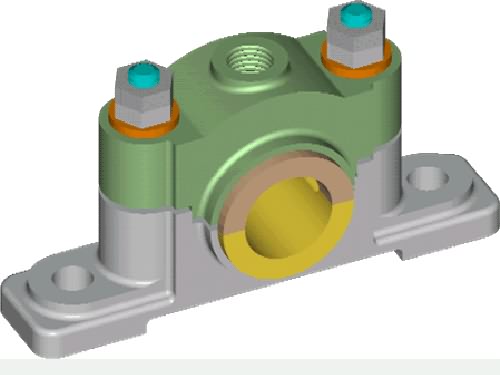

I-Plain bearing and bearing pedestal

Gear yakhelwe

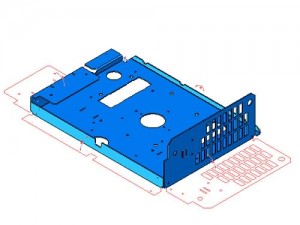

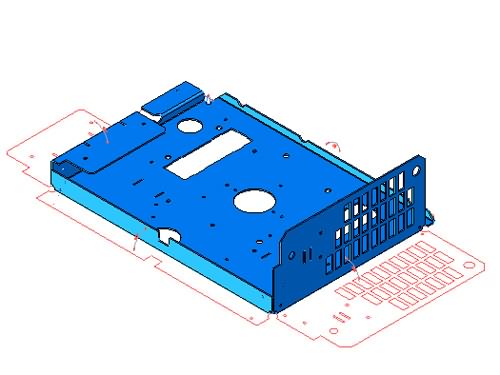

Stamping ingxenye

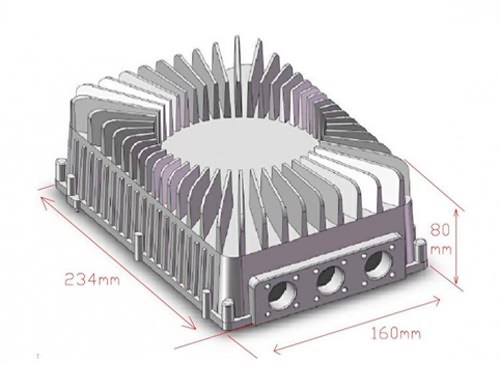

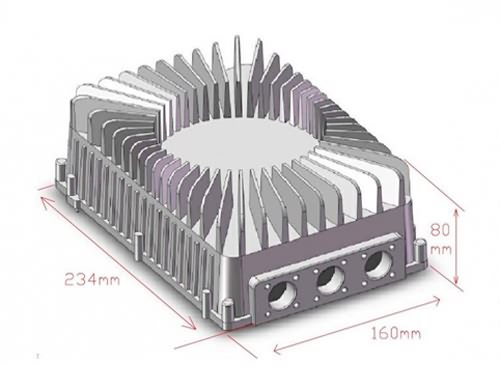

Aluminium izindlu

Uma ucabangela izidingo zobuchwepheshe bokucubungula zezingxenye, okungukuthi, ukwakheka kwezingxenye kufanele kubheke ubuchwepheshe bokucubungula obufanele ukuqinisekisa ukusebenza okudingekayo nokunemba, ukuthi ungabunciphisa kanjani ubunzima bokucubungula, izindleko kanye nokwenza ngcono umkhiqizo.

(1) Imishini: yezingxenye ezinezakhiwo eziqinile zomshini (amandla, ubulukhuni) nokunemba okuyisilinganiso nokuqina, okufana namagiya, ama-crankshafts, amabheringi nezinye izingxenye zokudlulisela zamathuluzi omshini noma imishini yokwakha, i-alloy yensimbi noma ithusi ivame ukukhethwa. Indlela machining ahlabayo ngomshini.

(2). stamping: izingxenye zepuleti ezincanyana, njengeziqukathi, amagobolondo, ama-lampshades noma izingxenye zeshidi, insimbi yensimbi noma isitampu ivame ukusetshenziswa. Ukunemba kwalobu buchwepheshe bokucubungula kuphansi kunokusika, ngakho-ke ezinye izingxenye ezinezidingo zokunemba kudingeka zenziwe ngomshini.

(3) I-die casting: kwezinye izingxenye ezinesimo esiyinkimbinkimbi, ikakhulukazi izingxenye zensimbi ezingezona i-ayoni, njengegobolondo lenjini, irediyetha nesiphathi sesibani esenziwe nge-aluminium alloy, zinc alloy, magnesium alloy and copper alloy, die casting molding can save very the inani lokusika futhi uthole izinga eliphezulu lokukhiqiza. Ifanele ukukhiqizwa ngobuningi.

(4) Obunye ubuchwepheshe bokucubungula: i-extrusion yensimbi ilungele ukukhiqizwa ngobuningi kwamaphrofayili wensimbi anezingxenye ezingaguquguquki, futhi i-powder sintering isetshenziselwa ukukhiqizwa okukhulu kwezingxenye zensimbi engagqwali.

IMestech inikezela ngamakhasimende nge-OEM design and processing of metal parts. Uma unesidingo noma udinga olunye ulwazi, sicela uxhumane nathi.