Faka ukubumba

Incazelo emfushane:

Faka ukubumbainqubo yokubumba ngomjovo wepulasitiki lapho kufakwa khona ipulasitiki emgodini futhi kuzungeze ucezu lokufaka noma izingcezu ezibekwe emgodini ofanayo ngaphambi kokubumba. Umphumela womkhiqizo wale nqubo ucezu olulodwa nokufakwa noma ukufakwa okufakwe ngaphakathi kwepulasitiki.

Faka ukubumbainqubo yokubumba ngomjovo wepulasitiki lapho kufakwa khona ipulasitiki emgodini futhi kuzungeze ucezu lokufaka noma izingcezu ezibekwe emgodini ofanayo ngaphambi kokubumba. Umphumela womkhiqizo wale nqubo ucezu olulodwa nokufakwa noma ukufakwa okufakwe ngaphakathi kwepulasitiki.

Ukufaka ukubumba kukhulisa amandla epulasitiki futhi kungasiza ekwehliseni izindleko zemikhiqizo ngokunciphisa inani lezinsimbi ezibizayo ezidingekayo ekwenzeni imikhiqizo. Isihlanganisi singenziwa ngensimbi noma enye ipulasitiki. Lolu hlobo lokubumba lwaqale lwakhiwa ukuze kufakwe okufakwe ezintanjeni ezingxenyeni ezibunjiwe futhi kufakwe uxhumano lwe-wire-plug ezintanjeni zikagesi.

Sandisa le nqubo yokubumba ukufeza izinto abanye ababunji abangakwazi noma abangeke bazenze.

Ngokuya ngosayizi wengxenye, kungenziwa isikhunta semigodi eminingi ukwandisa umkhiqizo. Imisebenzi yokubumba okuthunyelwe kwesibili kwesinye isikhathi iyadingeka ukuqeda umhlangano.

Faka ukubumba kuyindlela yokubumba ukuthi isikhunta sisetshenziselwa ukujova i-resin kokufakiwe okulungiselelwe ngezinto ezahlukahlukene, futhi into encibilikisiwe ihlanganiswe nokufakwa ukwenza umkhiqizo ohlanganisiwe. Izingxenye ezifakiwe ngokuvamile ziyizingxenye zensimbi, kodwa futhi nendwangu, iphepha, ucingo, ipulasitiki, ingilazi, ukhuni, iringi yocingo, izingxenye zikagesi.

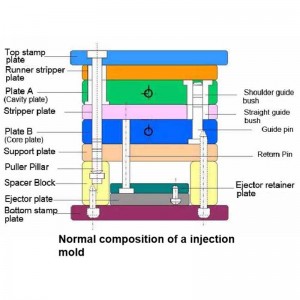

Inqubo yezici ze-Insert molding imi kanje:

1. Kuyadingeka ukuthi kubhekwe ukuhlanganiswa nokwengezwa kokuqina okucishe kube lula kwe-resin, ukugoba, ukuqina kwensimbi, amandla kanye nokumelana nokushisa, ukuze kwenziwe umkhiqizo ohlanganisiwe nophelele wensimbi owenziwe ngopulasitiki.

2. Ikakhulu, inhlanganisela ye-resin insulation kanye ne-conductivity yensimbi iyasetshenziswa, futhi imikhiqizo eyakhiwe ingahlangabezana nemisebenzi eyisisekelo yemikhiqizo kagesi.

3. Inhlanganisela yangaphambi kokufakwa kokufaka okuningi yenza ubunjiniyela bokuthunyelwe bokuhlanganiswa kweyunithi yomkhiqizo kunengqondo.

4. Imikhiqizo yokufaka ayigcini ngensimbi, kodwa futhi nendwangu, iphepha, ucingo, ipulasitiki, ingilazi, ukhuni, ikhoyili, izingxenye zikagesi, njll.

5. Ngemikhiqizo eqinile yokubumba kanye nemikhiqizo yokubumba enwebeka kupuleti lesisekelo senjoloba, ukusebenza okuyinkimbinkimbi kokuhlela amasongo wokuvala kungagwenywa ngemuva kokuthi imikhiqizo edidiyelwe yenziwe ngomjovo wokubumba ku-substrate, okwenza inhlanganisela ezenzakalelayo izinqubo ezalandela zaba lula.

6. Ngenxa yokuthi ilinhlanganisela yezinto ezincibilikisiwe nokufakwa kwensimbi, igebe phakathi kokufakwa kwensimbi lingahle linciphise futhi ukuthembeka kokubumba kwemikhiqizo ehlanganisiwe kuphakeme kunalokho kokucindezela ekubunjweni ..

7. Khetha i-resin efanelekile kanye nezimo zokubumba, okusho ukuthi, kwimikhiqizo elula ukonakala (njengeglasi, ikhoyili, izingxenye zikagesi, njll.), Nazo zingavalwa futhi zilungiswe yi-resin.

8. Ngokuhlanganiswa komshini wokujola omile mpo kanye ne-manipulator, isethi yonke yokufakwa njalonjalo, iningi lamaphrojekthi wokufaka wokufaka angabona ukukhiqizwa okuzenzakalelayo.

9. ngemuva kokuthi ukwakhiwa kufakiwe, kungabuye kwenziwe ngemikhiqizo enezimbobo eziyize ngemuva kokwelashwa okuyisisekelo kokukhishwa komgodi.

Amathiphu ekwakhiweni kwengxenye nokubunjwa kokufaka udini

Izidingo zezinto ezibonakalayo zokufakwa: ubulukhuni, iphuzu lokuncibilika, ukuqina, ukuncipha

2. Ukuthi umumo nosayizi wokufaka kulungele ukuthatha, ukubeka nokubeka kahle. Ukwakheka kwezingxenye kuzoba lula ukufakwa nokulungiswa kusikhunta ukuvikela izingxenye ekuphambukeni noma ekuthambekeni ngaphansi komthelela we-resin egelezayo.

3. Ukunemba kokukhiqiza nokungaguquguquki kokufakwa

4. Khetha isakhiwo sesikhunta esifanele, futhi okufakwayo nakho kungavalwa ngokuphelele ku-resin.

5. Ukuncipha okwenziwe kokufakwa kwensimbi kulula ukungalingani. Ukuhlolwa komkhawulo wokunemba kokuma nosayizi wezingxenye ezibalulekile kufanele kwenziwe ngaphambi kwesikhathi.

6. Ngesikhathi senqubo yokujova, ukufakwa kwensimbi kulula ukukhubazeka nokushintsha, ngakho-ke ukwakheka kwesikhunta kanye nokwakheka kwesimo sesikhunta okulula ukugcina ukufakwa kwensimbi kufanele kubhekwe ngokuphelele. Emikhiqizweni omumo wayo wokufaka ongenakuguqulwa, ukuhlolwa kwangaphambilini kubalulekile.

7. Qinisekisa ukuthi okufakwayo kwensimbi kudinga ukwelashwa ngaphambi kokushisa noma ukomiswa. Inhloso ukuqinisekisa ikhwalithi yomkhiqizo nokwakha uzinzo.

Izicelo ezijwayelekile:

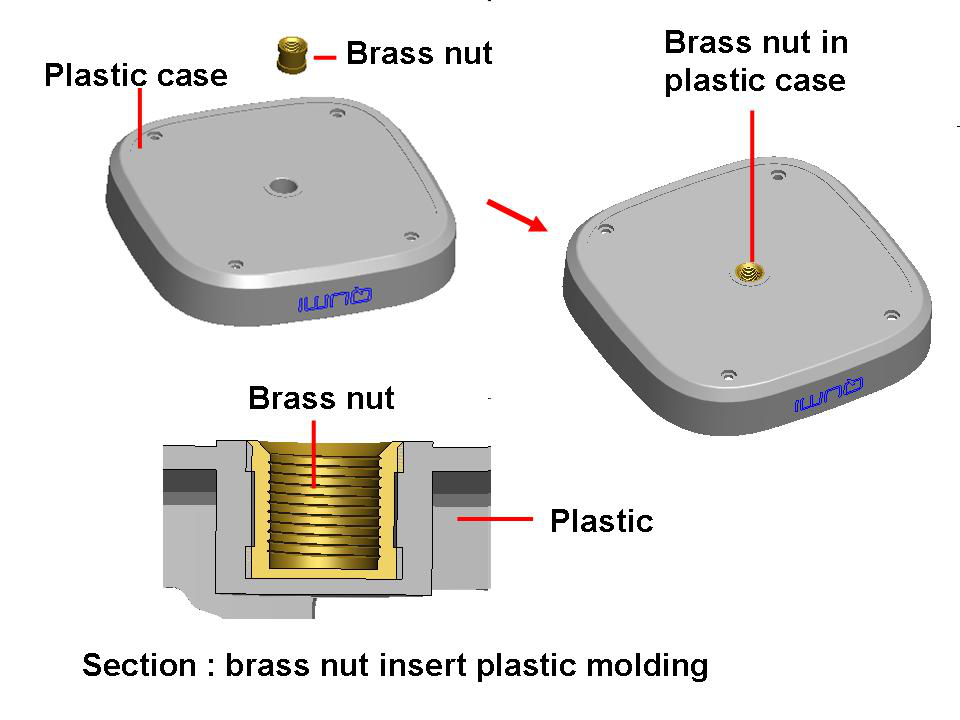

Metal faka udini Insimbi yokubumba insimbi iyinqubo yokubumba yokufaka esetshenziswa kakhulu kunazo zonke.

Insimbi yokufaka udaka uhlobo lwendlela yokulungisa ukufaka insimbi endaweni efanele kusikhunta kusengaphambili, bese ufaka ipulasitiki yokubumba. Ngemuva kokuthi kuvulwe isikhunta, okufakwayo kusongwa kumkhiqizo ngokupholisa nokuqinisa ipulasitiki ukuthola umkhiqizo ngokufakwa okufana nendandatho enezintambo ne-electrode.

Kuyadingeka ukuthi izingxenye zokufakwa kwensimbi ezishumekiwe kufanele zibe nokwakheka okufanelekile nobukhulu, futhi izingxenye zokufakwa okungaguquki kusikhunta zingabekwa ngokushesha futhi ngokuthembekile ukuvimbela ipulasitiki ekugelezeni emigodini yokulungisa. Ukufakwa nakho kudinga ukwakhiwa ngokukhethekile, njengokugoqa, ukugunda, ukusonta, njll ezingxenyeni ezishumekiwe ukuqinisekisa ukulungiswa kwazo okuthembekile ngaphakathi kwepulasitiki

Kwenziwe ngentando metal faka udini izingxenye:

IMestech uhlelo olukhethekile lokufaka udini .. Sicela uxhumane nathi ukukusiza ukuthola isixazululo esifanele sokubumba sohlelo lwakho lokusebenza.

Amandla plug ukufaka umjovo udini

Ithusi lethusi lifaka ukubumba

Precision ipuleti lensimbi faka udini