Umshini womjovo wePlastiki

Incazelo emfushane:

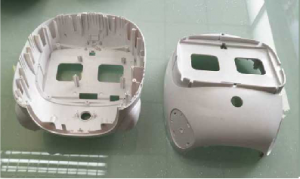

IMestech ifakwe ama-30 upulasitiki imishini yokubumba umjovokusuka kumathani ayi-100 kuye kumathani ayi-1500 no-10 abanolwazi lokusebenza abanolwazi. Singahlinzeka ngemikhiqizo yokubumba umjovo yobukhulu obuhlukahlukene kumakhasimende ethu

Umjovo wepulasitiki umshini ubizwa nangokuthi umjovo wokubumba umshini noma umshini wokujova. Kuyinto imishini esemqoka yokubumba eyenza ipulasitiki ye-thermoplastic noma i-thermosetting ibe yimikhiqizo epulasitiki yezimo ezahlukahlukene ngokusebenzisa isikhunta sokubumba sepulasitiki. Imisebenzi yomshini wokufaka umjovo wepulasitiki ukufudumeza amapulasitiki, ukusebenzisa ingcindezi ephezulu kuma-plastiki ancibilikisiwe, futhi kuwenze aqhume futhi agcwalise isikhunta.

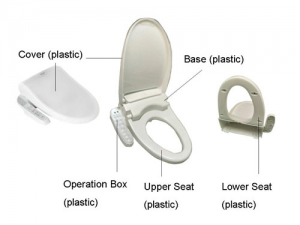

I-Ukwahlukaniswa komshini wokufaka umjovo wepulasitiki Umshini wokubumba umjovo weplastiki unamandla okwakha imikhiqizo epulasitiki enokubukeka okuyinkimbinkimbi, usayizi oqondile noma ukujiya okuminyene ngokufakwa kwensimbi ngesikhathi esisodwa. It is kabanzi kwezokuvikela kazwelonke, electromechanical, yezimoto, ezokuthutha, izinto zokwakha, ukupakisha, ezolimo, isiko, ezemfundo, ezempilo kanye nempilo yabantu yansuku zonke. Ngokuthuthuka okusheshayo komkhakha wepulasitiki kanye nesakhiwo esiyinkimbinkimbi nemisebenzi yemikhiqizo yokubumba, izinhlobo ezahlukahlukene nokucaciswa kwemishini yokubumba umjovo kuthuthukiswe ngokufanele. Ngokuya ngokunemba kwemikhiqizo ekhiqizwayo, imishini yokujova ingahlukaniswa ngemishini ejwayelekile kanye nokunemba yomjovo. Ngokuya ngohlelo lokulawula amandla, umshini wokujova ungahlukaniswa ube yi-hydraulic nayo yonke imishini yokubumba umjovo kagesi. Ngokuya ngesimo sesakhiwo somshini wokubumba umjovo, kunezinhlobo ezintathu: mpo futhi ivundlile (kufaka phakathi umshini wokujova umbala wombala) nohlobo lwe-engeli.

Isingeniso sezici zemishini ehlukahlukene yokujova umjovo

5. Idivayisi ejwayelekile yokukhiya isikhunta ivulekile nxazonke, kulula ukumisa zonke izinhlobo zamadivayisi we-othomathikhi, efanelekayo ngemikhiqizo eyinkimbinkimbi, eyinkimbinkimbi yokubumba okuzenzakalelayo.

6. idivayisi yokuhambisa ibhande kulula ukubona ukufakwa okuphakathi ngokusebenzisa isikhunta, ukuze kube lula ukukhiqizwa okuzenzakalelayo.

7. kulula ukuqinisekisa ukungaguquguquki kokugeleza kwe-resin nokusatshalaliswa kokushisa kwesikhunta kusikhunta.

8. Ifakwe itafula elijikelezayo, itafula elihambayo netafula elithambekele, kulula ukubona ukufaka ukubumba nokufa ukubumbana kokuhlanganiswa.

Ukukhiqizwa kwesilingo esincane se-batch, isakhiwo sesikhunta silula, izindleko eziphansi, futhi kulula ukukhipha.

10. umshini mpo ngenxa maphakathi namandla adonsela phansi, ukumelana kuqhathaniswa evundlile zokuzamazama komhlaba kungcono.

1.Horizontal umjovo udini umshini

Noma ngabe iframeframe iphansi ngenxa ye-fuselage yayo ephansi, awukho umkhawulo wokuphakama esitshalweni.

Umkhiqizo we-2.Ungawa ngokuzenzakalela, ngaphandle kokusetshenziswa kwesandla somshini, ukubumba okuzenzakalelayo kungatholakala.

3.ngoba i-fuselage ephansi, ukudla okulula, ukugcinwa okulula.

4.mold kufanele ifakwe yi-crane.

Ukuhlelwa kwe-5.multiple parallel, umkhiqizo obunjiwe kulula ukuwuqoqa nokupakisha kusuka ebhandeni elihambayo.

2.Vertical umjovo udini umshini

1. umshini wokujova nedivayisi yokubopha ikulayini owodwa omile mpo, bese kuthi idayivu ivulwe futhi ivalwe eceleni kwezinkomba ezingenhla nezingezansi. Indawo yaso yaphansi icishe ibe yingxenye yomshini ovundlile, ngakho-ke ukuguqulwa kube yindawo yokukhiqiza cishe kabili kokukhiqizwa.

2. kulula ukufeza ukufaka ukubumba. Ngoba indawo yokufa iphezulu, ukufakwa kulula ukuthola. I-othomathikhi yokufaka i-othomathikhi ingabonakala kalula ngokwamukela uhlobo lomshini ngesifanekiso esiphansi esilungisiwe nethempulethi ephezulu ehambayo kanye nenhlanganisela

ibhande elihambayo kanye ne-manipulator.

3. Isisindo sikadayi siyavulwa futhi sivalwe phezulu naphansi ngokuxhaswa kwefomu evundlile. Isimo sokuthi ifomu alikwazi ukuvulwa futhi livalwe ngenxa yokuguqulwa okuphambili okubangelwe amandla adonsela phansi afana nomshini ovundlile ngeke kwenzeke. Kuyasiza ukugcina ukunemba kwemishini futhi kufe.

4. Nge-manipulator elula, umgodi ngamunye wepulasitiki ungasuswa, olungele ukubunjwa ngokunemba.

3.Double umjovo udini umshini

Ingabe umjovo wesikhathi esisodwa ungabumba imibala emibili yomshini wokujova umjovo, ungahlangabezana nezidingo zabathengi zokubukeka, abasebenzisi bangawusebenzisa umkhiqizo ngokunethezeka.

4.All kagesi umjovo udini umshini

Zonke-kagesi umjovo udini umshini abakwazi kuphela ukuhlangabezana nezidingo izicelo ezikhethekile, kodwa futhi kunezinzuzo ezingaphezu kuka ezejwayelekile umjovo udini umshini.

Enye inzuzo yomshini wokubumba umjovo onawo wonke amandla kagesi ukuthi wehlisa umsindo, ongazuzisi nje kuphela abasebenzi, kodwa futhi owehlisa utshalomali ezitshalweni ezikhiqiza umsindo.

5.Angle umjovo udini umshini

I-eksisi yomjovo isikulufa se-engeli umjovo udini umshini is perpendicular to the axis moving of clamping mechanism template, and its benefits and nebours are between vertical and horizontal. Ngoba ukuqondiswa komjovo nobuso bokuhlukaniswa kwesikhunta busendizeni efanayo, umshini wokubumba umjovo we-angular ulungele isikhunta nge-geometry engalingani yesango lohlangothi noma imikhiqizo isikhungo sayo sokubumba esingavumeli amamaki esango.

Umshini wokubumba wesiteshi se-6.Multi

Idivayisi yokujova nedivayisi yokubamba inezikhundla ezimbili noma ngaphezulu zokusebenza, futhi idivaysi yokujova nedivayisi yokubopha ingahlelwa ngezindlela ezahlukahlukene.

Njengamanje, izinhlobo ezintathu zemjovo yokubumba imishini zisetshenziswa kabanzi:

Ovundlile umjovo udini umshini kabanzi ngoba isikhala yayo encane, ukufakwa elula futhi ububanzi isicelo ububanzi. Imishini yokubumba umjovo ophindwe kabili isetshenziselwa ikakhulu ukubekwa uphawu kanye nezidingo zokuvimbela ukungena kwemikhiqizo ye-elekthronikhi, ukushaqeka kubhaqa amathuluzi kagesi, nemikhiqizo enemibala ehlukahlukene nesakhiwo esihlangene. Yonke-kagesi umjovo udini umshini isetshenziswa ekukhiqizeni oda ezinkulu, ngokunemba high izingxenye ezincane naphakathi.

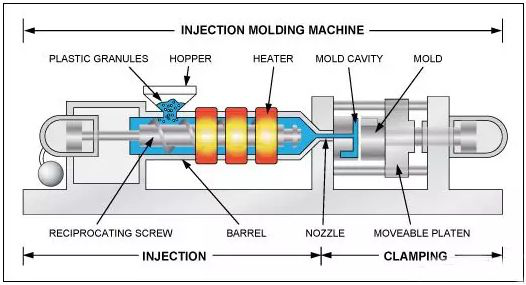

II-Ngabe imishini yokufaka umjovo wepulasitiki isebenza kanjani?

Isimiso esisebenzayo somshini wokujova umjovo siyefana nesirinji yomjovo. Kuyinqubo yezobuchwepheshe yokujova ipulasitiki encibilikisiwe (okusho ukugeleza okunamandla) emgodini ovaliwe ngokusebenzisa umfutho wesikulufu (noma i-plunger) nokuthola umkhiqizo ngemuva kokuphulukisa.

Umjovo wokubumba inqubo eyindilinga, umjikelezo ngamunye ikakhulukazi uhlanganisa:

Ukudla okulinganiselwe - ukuncibilika kwepulasitiki - umjovo wokucindezela - ukupholisa - ukuvulwa kwesikhunta nokuthatha izingxenye. Susa izingxenye zepulasitiki bese uvala isikhunta kumjikelezo olandelayo.

Izinto zomshini wokubumba umjovo wezinto: izinto zomjovo wokubumba umjovo zihlanganisa ukusebenza kwekhibhodi yokulawula, ukusebenza kohlelo lokulawula kagesi nokusebenza kohlelo lwe-hydraulic lwezinto ezintathu. Ukukhethwa kwesenzo senqubo yokujova, isenzo sokuphakela, ingcindezi yomjovo, isivinini somjovo, uhlobo lokukhishwa, ukuqapha izinga lokushisa kwengxenye ngayinye yomgqomo, ingcindezi yomjovo nokulungiswa kwengcindezi emuva kwenziwa ngokulandelana.

Inqubo yokubumba ejwayelekile yomshini wokujola we-screw injection yile: okokuqala, i-granular noma i-powder plastic yengezwa emgqonyeni, bese ipulasitiki incibilika ngokuzungezisa isikulufa nokushisa komgqomo wangaphandle odongeni. Ngemuva kwalokho umshini wenza isikhunta nesihlalo somjovo siqhubekele phambili, ukuze umbhobho usondele esangweni lesikhunta, bese kuthi uwoyela wengcindezi uthelwe kusilinda womjovo ukwenza isikulufu. Induku iqhutshelwa phambili ukuze ukuncibilika kujojowe ku-die evaliwe ngokushisa okuphansi ngomfutho ophakeme nangejubane eliphezulu. Ngemuva kwenkathi ethile yesikhathi nokucindezela ukubamba (okwaziwa nangokuthi ukubamba ingcindezi) nokupholisa, ukuncibilika kuqinisiwe futhi kubunjwe, futhi umkhiqizo ungakhishwa (inhloso yokubamba ingcindezi ukuvimbela ukucibilika kokuncibilika emgodini futhi unikeze okokusebenza emgodini.Futhi uqinisekise ukuthi umkhiqizo unokubekezelelana okuthile nokubekezelelana kobuso.Izidingo eziyisisekelo zomjovo wokujova i-plasticization, umjovo nokubumba.Plasticization yisisekelo sokufeza nokuqinisekisa ikhwalithi yemikhiqizo yokubumba, futhi ukuze kuhlangatshezwane nezidingo zokubumba, umjovo kufanele uqinisekise ukucindezela okwanele nejubane.Ngasikhathi sinye, ngoba ingcindezi yomjovo iphakeme kakhulu, ihambelana nengcindezi ephezulu emgodini (ingcindezi emaphakathi emgodini ngokuvamile iphakathi kuka-20 no-45 MPA), ngakho-ke kufanele kube namandla anele okubambelela.Kungabonakala ukuthi idivaysi yomjovo nedivayisi yokubamba kuyizingxenye ezisemqoka zomshini wokubumba umjovo.

Ukuhlolwa kwemikhiqizo yepulasitiki ikakhulu kufaka izici ezintathu: eyokuqala ikhwalithi yokubukeka, kufaka phakathi ubuqotho, umbala, ubukhazikhazi, njll. okwesibili ukunemba phakathi kosayizi nendawo yesihlobo; okwesithathu yizici zomzimba, zamakhemikhali nezikagesi ezihambelana nokusetshenziswa. Lezi zidingo zekhwalithi futhi zihlukile ngokuya ngezikhathi ezahlukahlukene zemikhiqizo. Ukukhubazeka kwemikhiqizo ikakhulukazi kulele ekwakhiweni, ukunemba nokugqokwa kwezinga lesikhunta. Kepha empeleni, ochwepheshe besitshalo sokulungisa ipulasitiki bavame ukubhekana nesimo esinzima sokusebenzisa izindlela zobuchwepheshe ukulungisa izinkinga ezibangelwa ukukhubazeka kwesikhunta futhi zingabi namphumela omncane.

Ukulungiswa kwenqubo kuyindlela edingekayo yokwenza ngcono ikhwalithi nokukhishwa kwemikhiqizo. Ngoba umjikelezo womjovo ngokwawo mfushane kakhulu,

uma izimo zenqubo zingalawulwa kahle, imikhiqizo kadoti izohamba ngokuqhubekayo. Lapho ulungisa inqubo, kungcono ukushintsha isimo esisodwa kuphela ngasikhathi sinye bese usigcina kaningi. Uma ingcindezi, izinga lokushisa nesikhathi kuhlangene futhi kwalungiswa, kulula ukudala ukudideka nokungaqondi. Ziningi izindlela nezindlela zokulungisa inqubo. Isibonelo, kunezixazululo ezingaphezu kweshumi ezingaba khona enkingeni yomjovo ongagculisi wemikhiqizo. Ukukhetha isixazululo senkinga kuphela lapho singakwazi ukuxazulula inkinga eyodwa noma ezimbili. Ngaphezu kwalokho, kufanele futhi sinake nobudlelwano besigodi kusixazululo. Isibonelo: umkhiqizo unesifo sokudangala, kwesinye isikhathi ukukhuphula izinga lokushisa kwezinto ezibonakalayo, kwesinye isikhathi ukwehlisa ukushisa kwempahla; kwesinye isikhathi ukwandisa inani lezinto ezibonakalayo, kwesinye isikhathi ukunciphisa inani lezinto ezibonakalayo. Vuma ukuthi kungenzeka yini ukuxazulula inkinga ngezinyathelo eziguqukayo.

III-The main nemingcele technical umjovo udini umshini kukhona

Amandla okuvala, ivolumu yomjovo ophakeme, ubukhulu obukhulu bokufa, ubukhulu bokushintshwa kwesikhunta, ibanga phakathi kwezinduku zokudonsa, ukushaywa unhlangothi nokucindezelwa kokukhishwa, njll.

Izidingo zobuchwepheshe zemishini yokubumba umjovo efanelekayo ekubunjweni kwemikhiqizo zingakhethwa ngokulandelayo:

1 Amandla okubamba: indawo yokuqagela yomkhiqizo iphindaphindwe ngomsindo wesikhunta somgogodla ongaphansi kwamandla okubamba, i-P ilingana noma ilingana nengcindezi yomgodi we-QF;

2 Umthamo omkhulu womjovo: isisindo somkhiqizo <ivolumu enkulu yomjovo. Isisindo somkhiqizo = ivolumu ephezulu yomjovo * 75 ~ 85%.

3 Injection udini umshini isikhunta ukujiya: isikhawu phakathi inani eliphakeme futhi ubuncane umshini umjovo udini kanye amaphuzu amabili. Isikhunta esiphezulu ukujiya umjovo udini umshini esingaphansi esiphezulu isikhunta ukujiya isikhunta. The ukushuba ubuncane ilingana ubuncane isikhunta ukushuba womjovo udini umshini.

Isikhunta sohlangothi: ibanga lokuvula isikhunta = isikhunta ukujiya + ukuphakama komkhiqizo + ibanga lokukhishwa + isikhala somkhiqizo. Okusho ukuthi, isikhunta-isikhunta ibanga.

5 Ibanga phakathi kwezinduku: lokho ukufaka isikhundla sesikhunta; ubude besikhunta * ububanzi bungaphansi kwebanga lokudonsa.

I-6 Ejection stroke nengcindezi: ibanga lokukhishwa komkhiqizo nengcindezi <ejection stroke nengcindezi yomshini wokubumba umjovo.

Uhlelo nokwakheka komshini wokujova

Umjovo wokubumba umshini imvamisa uqukethe uhlelo lokujova, uhlelo lokuvala isikhunta, uhlelo lokudlulisela amanzi, uhlelo lokulawula ugesi, uhlelo lokuthambisa, ukufudumeza nokupholisa uhlelo, uhlelo lokuqapha ukuphepha nokunye.

Uhlelo lokujova

Umsebenzi wohlelo lokujova: Uhlelo lokujova lungenye yezingxenye ezibaluleke kakhulu zomshini wokujova umjovo, ngokuvamile kunezinhlobo ezintathu eziyinhloko zeplunger, isikulufa, isikulufa somjovo wangaphambi kwepulasitiki. Uhlobo olusetshenziswa kakhulu isikulufa. Umsebenzi wawo ukufaka ipulasitiki encibilikisiwe embotsheni yesikhunta ngesikulufa ngaphansi kwengcindezi ethile nejubane ngemuva kokufaka inani elithile lamapulasitiki ngesikhathi esinqunyiwe emjikelezweni womshini wokujova. Ngemuva komjovo, ukuncibilika okujojowe emgodini wesikhunta kugcinwa kusesimweni.

Uhlelo lokujova luqukethe i-plasticizing device nedivayisi yokudlulisa amandla.

Idivayisi yokufaka ipulasitiki yomshini wokufaka umjovo wesikulufa ikakhulukazi yakhiwe ngedivayisi yokuphakela, umgqomo, isikulufa, ingxenye yokudlula yeglue nombhobho. Idivayisi yokudlulisa amandla ifaka isilinda somjovo, isilinda esinyakazayo sesihlalo somjovo nedivayisi yesikulufu (a

Isikhunta clamping uhlelo

Umsebenzi wokuqinisa uhlelo: umsebenzi wokuqinisa uhlelo ukuqinisekisa ukuvalwa kwesikhunta, ukuvula nokukhishwa kwemikhiqizo. Ngasikhathi sinye, ngemuva kokuthi isikhunta sivaliwe, kunikezwa amandla anele okubamba ukumelana nengcindezi yomgodi wesikhunta obangelwa ipulasitiki elincibilikile elingena emgodini wesikhunta, futhi umthungo wesikhunta uyavinjelwa, okuholela esimweni esibi semikhiqizo.

Ukwakheka kohlelo lokuminyanisa: uhlelo lokuqinisa kakhulu lwakhiwe ngocingo lokuqinisa, indlela yokulenga, indlela yokulungisa, indlela yokukhipha, ithempulethi elingaphambili nangemuva elihleliwe, ithempulethi ehambayo, isilinda sokuqinisa kanye nendlela yokuvikela ukuphepha.

Uhlelo umfutholuketshezi

Umsebenzi wohlelo lokudlulisela umfutholuketshezi ukuhlinzeka amandla ngomshini wokubumba umjovo ngokuya ngezenzo ezahlukahlukene ezidingekayo ngenqubo, nokuhlangabezana nezidingo zengcindezi, isivinini kanye nokushisa okudingwa yizingxenye ezahlukahlukene zomshini wokubumba umjovo. It is ikakhulukazi yakhiwa izingxenye ezehlukene wokubacindezela kanye izingxenye wokubacindezela wokubasiza, lapho uwoyela futha futhi motor kukhona umthombo wamandla umjovo udini umshini. Amaphayiphu ahlukahlukene alawula ukucindezela kukawoyela nokugeleza kwawo, ukuze ahlangabezane nezidingo zenqubo yokubumba umjovo.

Uhlelo lokulawula ugesi

Ukudidiyela okunengqondo phakathi kohlelo lokulawula kagesi nohlelo lwe-hydraulic kungazifeza izidingo zenqubo (ingcindezi, izinga lokushisa, isivinini, isikhathi) kanye nezenzo ezahlukahlukene zohlelo lomshini wokujova. It is ikakhulukazi yakhiwe ngogesi, izinto zikagesi, izinsimbi (bheka ngezansi kwesokudla), heater, izinzwa nokunye. Ngokuvamile, kunezindlela ezine zokulawula, ezenziwa ngesandla, ezizenzekelayo, ezizenzekelayo nezilungisiwe.

Ukushisa / ukupholisa uhlelo

Uhlelo lokushisa lusetshenziselwa ukufudumeza umgqomo nombhobho womjovo. Umgqomo womshini wokubumba umjovo ngokuvamile usebenzisa ikhoyili yokushisa kagesi njengedivayisi yokushisa, efakwe ngaphandle komgqomo futhi ihlukaniswe yi-thermocouple. Ukushisa kokushisa kokufakwa kwempahla nge-tube wall conduction; uhlelo lokupholisa lusetshenziselwa ukupholisa ukushisa kukawoyela, ukushisa kukawoyela okuphezulu kakhulu kuzodala amaphutha ahlukahlukene, ngakho-ke izinga lokushisa likawoyela kufanele lilawulwe. Enye indawo ezopholisa iseduze nechweba lokukhipha lepayipi lokudla ukuvimbela ukuthi impahla eluhlaza ingancibiliki esikhumulweni sokukhipha, okuholela ekutheni impahla eluhlaza ingondliwe kahle.

Uhlelo lokuthambisa

Uhlelo Lubrication luyisifunda esinikeza isimo sokuthambisa sezingxenye ezihambisanayo zomshini wokujova umjovo, njengokuhambisa ithempulethi, ukulungisa idivayisi, ukuxhuma i-hinge kanye netafula lokudubula, ukuze kunciphise ukusetshenziswa kwamandla futhi kuthuthukise impilo yezingxenye. Ukumanzisa kungaba ukuthambisa mathupha njalo noma ukuthambisa okuzenzakalelayo kagesi.

Uhlelo lokuqapha ukuphepha

Idivayisi yokuphepha yomjovo wokubumba umshini isetshenziswa ikakhulukazi ukuvikela abantu namadivayisi okuphepha komshini. Ikakhulu ngasemnyango wezokuphepha, ukudideka kwezokuphepha, i-valve yokubacindezela, iswishi yomkhawulo, izingxenye zokutholwa kwe-photoelectric nezinye izinto, ukufeza ugesi - Ukuvikelwa okuhlanganiswayo kwe-hydraulic.

Uhlelo lokuqapha ikakhulukazi luhlola ukushisa kukawoyela, ukushisa kwempahla, ukulayishwa kwesistimu, inqubo kanye nokwehluleka kwemishini yomshini wokubumba umjovo, futhi kukhombisa noma kulayishe isimo esingajwayelekile.

IMestech ifakwe umshini wokufaka umjovo wama-30 ohlanganisa amathani ayi-100 kuye kumathani ayi-1500, singakhiqiza umkhiqizo wepulasitiki kusuka ku-0.50 amagremu kuye ku-5 kg wezingxenye zepulasitiki ezinobukhulu obuhlukahlukene. Uma unemikhiqizo epulasitiki edinga umjovo wokubumba, sicela uxhumane nathi