Ukufakwa kweplastiki kwe-electroplating kanye ne-vacuum

Incazelo emfushane:

Ukufakwa kwe-Electroplating kanye ne-vacuum kuyizinqubo ezimbili ezijwayelekile zokungeza ukumbozwa kwensimbi ezingxenyeni zepulasitiki. Le nqubo ingakhuphula ukumelana nokugqoka nokuqina kokugqwala kwezingxenye zezingxenye, kwandise ukuthungwa kwensimbi futhi kuhlobise ukubukeka.

Uma kuqhathaniswa nopende wokufafaza, i-plastic electroplating kanye ne-vacuum plating inokuqina kokugqoka okungcono, ukumelana nokugqwala nokukhanya okuhlukile kwensimbi. Isetshenziswa kakhulu kwezinye izingxenye zomkhiqizo osezingeni eliphezulu, njengokufakwa kwemikhiqizo yemultimedia, amakesi wokubuka ama-smart, izinkinobho, izibani zamalambu, amathunzi nezibani.

Imigomo ye-electroplating kanye ne-vacuum plating yehlukile, futhi izinto ezisebenzayo nemiphumela yehlukile. Ake sethule ngezansi:

1. Ukuqhuma kweplastiki

I-plastic electroplating inqubo yokufaka izingxenye zepulasitiki ku-electrolyte nokufaka izinhlayiya zensimbi ebusweni bomsebenzi ngokulayisha ukusabela kwamanje noma kwamakhemikhali. Ngemuva kwe-electroplating, umbala ongaphezulu kwesiliva, isiliva elincane nesiliva elimpunga.

Amapulasitiki e-ABS afakwa kusengaphambili ngenqubo yethusi yesiliva ye-nitrate yamakhemikhali, i-colloidal palladium PD nickel yamapuleti aqondile ukukhiqiza ungqimba oluqhubayo olunamathela kahle ebusweni balo, bese kuthi ezinye izinsimbi zenziwe ugesi.

I-Electroplating yenziwa ngesisombululo samanzi se-electrolytic, ngakho-ke ibizwa ngokuthi "i-electroplating water", "i-hydropower plating". Okuvame kakhulu ukufakwa kwepulangwe ebusweni bepulasitiki, i-nickel chromium, i-chromium ethandekayo, umbala wesibhamu, i-pearl nickel njalonjalo.

Ngokombono, wonke amapulasitiki angafakwa ngogesi, kepha okwamanje i-ABS, i-ABS + PC yiyona ephumelela kakhulu, kepha ukunamathiselwa kwengubo yokugcotshwa kwamanye ama-plastiki akuneliseki. Inqubo ye-electroplating yamanzi ilula futhi ayidingi ukufafaza i-primer ngaphambi nangemva kokufakwa. Ukumboza kunokunamathela okuhle, ukumboza okunamandla nezindleko eziphansi.

2.Ukufakwa kweplastiki, (i-Physical Vapor Deposition-PVD)

Ukufakwa kwepayipi ikakhulu kufaka phakathi ukuhwamuka komshini, ukugxuma kanye nokufakwa kwe-ion. Bonke bafaka amafilimu ahlukahlukene ensimbi nangensimbi ebusweni bepulasitiki

izingxenye nge-distillation noma i-sputtering ngaphansi kwe-vacuum. Ngale ndlela, ingubo yokumboza encane kakhulu ingatholakala.

Umshini wokugcoba ikakhulukazi ufaka isikhala sokuhwamuka komshini, ukugoqeka kwesikhala nokufakwa kwe-ion. Onke asetshenziselwa ukufaka izinsimbi ezahlukahlukene ebusweni bezingxenye zepulasitiki nge-distillation noma i-sputtering ngaphansi kwezimo ze-vacuum.

Ifilimu engeyona eye-metallic, ngale ndlela ingaba mncane kakhulu ekugqokeni indawo, futhi inezinzuzo ezivelele zejubane elisheshayo nokunamathela okuhle, kepha inani liphakeme, lisetshenziselwa ukuqhathanisa, ukumboza okusebenzayo kokumboza okuphezulu kungakhiqiza.

Umshini ungasetshenziswa kupulasitiki njenge-ABS, i-PE, i-PP, i-PVC, i-PA, i-PC, i-PMMA, njll. Ukumboza okuncane kungatholwa nge-plating plating.

Izinto zokugqoka zokugcoba zingafakwa ngezinsimbi ezahlukahlukene, njenge-aluminium, isiliva, ithusi negolide, ezinendawo encibilika ephansi kunentambo ye-tungsten.

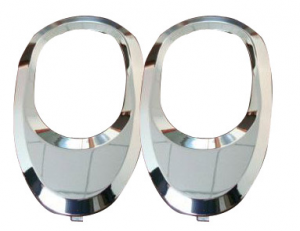

Ingxenye ye-Automobile ABS Electroplating

Izingxenye zepulasitiki ezine-nickle electroplating

High isicwebezelisi chrome electroplated izingxenye plastic

Izingxenye zepulasitiki ezenziwe ngombala ocwebezelayo ophakeme

3. Plating cleaner Plating (I-Physical Vapor Deposition-PVD)

Ukufakwa kwepayipi ikakhulu kufaka phakathi ukuhwamuka komshini, ukugxuma kanye nokufakwa kwe-ion. Bonke bafaka amafilimu ahlukahlukene ensimbi nangensimbi ebusweni bepulasitiki

izingxenye nge-distillation noma i-sputtering ngaphansi kwe-vacuum. Ngale ndlela, ingubo yokumboza encane kakhulu ingatholakala.

Umshini wokugcoba ikakhulukazi ufaka isikhala sokuhwamuka komshini, ukugoqeka kwesikhala nokufakwa kwe-ion. Onke asetshenziselwa ukufaka izinsimbi ezahlukahlukene ebusweni bezingxenye zepulasitiki nge-distillation noma i-sputtering ngaphansi kwezimo ze-vacuum.

Ifilimu engeyona eye-metallic, ngale ndlela ingaba mncane kakhulu ekugqokeni indawo, futhi inezinzuzo ezivelele zejubane elisheshayo nokunamathela okuhle, kepha inani liphakeme, lisetshenziselwa ukuqhathanisa, ukumboza okusebenzayo kokumboza okuphezulu kungakhiqiza.

Umshini ungasetshenziswa kupulasitiki njenge-ABS, i-PE, i-PP, i-PVC, i-PA, i-PC, i-PMMA, njll. Ukumboza okuncane kungatholwa nge-plating plating.

Izinto zokugqoka zokugcoba zingafakwa ngezinsimbi ezahlukahlukene, njenge-aluminium, isiliva, ithusi negolide, ezinendawo encibilika ephansi kunentambo ye-tungsten.

Lampshade cleaner Plating izingxenye zepulasitiki

Izingxenye zepulasitiki ze-UV

Umshini wokugcoba wenkomishi ekhombisa ipulasitiki

Izingxenye zepulasitiki zombala we-Nano

Uyini umehluko phakathi kokufakwa kwepulasitiki nokufakwa kwepulasitiki?

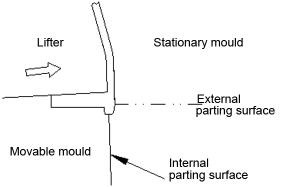

(1) Ukufakwa kwepayipi kuyinqubo yokumboza kulayini wokufafaza kanye nesithando somshini, kuyilapho i-electroplating iyinqubo yesixazululo samanzi. Ngoba ifafaza upende, i-vacuum plating ayifanele imikhiqizo eyakhiwe eyinkimbinkimbi, ngenkathi i-electroplating yamanzi ingavinjelwe ukwakheka.

(2) Icubungula ubuchwepheshe, njenge-vacuum coating of plastic glue, ingafingqwa ngokufingqiwe: i-surface surface degreasing, i-dedusting, i-electrostatic precipitation, i-spraying UV primer, i-UV elapha, i-vacuum enamathela, i-dedusting, i-spraying surface bottom (umbala we-concentrate ungangezwa) , ukwelapha, imikhiqizo eqediwe; i-vacuum coating inqunyelwe ngenqubo, futhi ayifanele ukucubungula imikhiqizo enendawo enkulu kakhulu ngenxa yomsebenzi. Inqubo yobuciko ayilawulwa kahle, futhi nezinga lokukhubazeka liphezulu.

I-plastic electroplating (imvamisa i-ABS, i-PC / i-ABS): amakhemikhali enza i-hydrophilic coarsening ukunciphisa ukunciphisa ukumiswa kwepalladium activation ukusheshisa i-electroless nickel plating hydrochloric acid activation coke copper sulfuric acid activation semi-bright nickel nickel uphawu chromium plating drying imikhiqizo eqediwe;

(3) Ukufaka ugesi kungaqedwa ekukhiqizeni okuzenzakalelayo ngokuphelele.

(4) maqondana nokubukeka, ukugqama kombala wefilimu ekhanyisiwe kukhanya kakhulu kunokukhanya kwe-chromium ekhethiwe.

(5) Ngokuqondene nokusebenza, ukumbozwa kwepulasitiki kuyingqimba engaphandle kakhulu kapende, kuyilapho i-electroplating yamanzi imvamisa i-chromium yensimbi, ngakho-ke ubulukhuni bensimbi bungaphezulu kunobenhlaka.

s ukumelana nokugqwala, ukumbozwa ngopende kuvame ukusetshenziswa. Isendlalelo sekhava singcono kunesendlalelo sensimbi, kodwa kukhona umehluko omncane phakathi kwazo kuzidingo zomkhiqizo ophezulu; kusimo sezulu, i-electroplating ingcono kunokufakwa kwepulangwe, ngakho-ke imvamisa idinga ukusetshenziswa kwangaphandle kwesikhashana nokumelana nesimo sezulu.

Emkhakheni wezimoto, kukhona nezidingo eziqinile zokumelana nokushisa okuphezulu phansi, umswakama nokushisa, ukusulwa kwe-solvent nokunye.

(6) Ukufakwa kwepayipi kusetshenziswa kakhulu embonini yezokuxhumana ngogesi, njengegobolondo likamakhalekhukhwini, izicelo zezimoto, njengezinkomishi ezibonisa izibani zezimoto; ukufaka amanzi kusetshenziselwa ikakhulukazi i-chromium yokuhlobisa, enjenge-trim door trim. Izinkinobho zeminyango njalonjalo.

(7) Ngokuya ngokuhlukahluka kombala okwehlukile komkhiqizo, iplathi ye-vacuum icebile kune-electroplating. Ukufakwa komshini kungenziwa ngegolide nakwezinye izindawo zombala.

(8) maqondana nezindleko zokucubungula, izindleko zokugcoba zamanje ziphakeme kunalezo zokufakwa kwamanzi.

(9) Ukupaka umshini kuyinqubo yokuvikela imvelo eluhlaza okhulayo ngenqubekela phambili yobuchwepheshe, kuyilapho i-electroplating yamanzi iyinqubo yendabuko enokungcola okuphezulu, futhi imboni ikhawulelwe ithonya lezinqubomgomo zikazwelonke.

(10) Nansi inqubo yokufafaza (i-silver mirror reaction) esanda kuvela. Le nqubo i-degreasing epulasitiki kanye ne-deelectrostatic primer baking nano-spraying baking pure water baking.

Lobu buchwepheshe bungenza nomphumela wesibuko ebusweni bepulasitiki. Kuyinqubo futhi enobungani bemvelo. Izinqubo zangaphambili nezokugcina ziyefana nokufakwa kwepulangwe, kepha kuphela okuphakathi nendawo.

I-Aluminium ithathelwa indawo yisibuko esifafazwe ngesiliva, kepha ukusebenza kwamanje kwezobuchwepheshe kwale nqubo akunakuqhathaniswa nokufakwa kophahla lwamanzi nokufakwa kwepulangwe. Ingasetshenziswa kuphela kumikhiqizo yezandla engadingi ukubonakala okuphezulu nokusebenza.

Umugqa wokukhiqiza

Umshini Plating amadivayisi izingxenye plastic

Umugqa wokukhiqiza we-Plastic electroplating

Uma imikhiqizo yakho inezingxenye zepulasitiki ezi-electroplated noma izingxenye zepulasitiki ezifakwe ngomshini sicela uxhumane nathi.