Ukwenziwa kwesibonelo ukwenza isampuli eyodwa noma eziningana ngokusho komklamo womdwebo noma ukukhulelwa komkhiqizo, ngokusebenzisa ezinye izindlela ezikhethekile zokucubungula, ngokuya ngezidingo zokubukeka komkhiqizo nesakhiwo sokudweba ngaphandle kwesikhunta sokukhiqiza.

I-prototype icishe ifane nomkhiqizo uqobo ngokuma, umbala nokuma. Isetshenziselwa ukuqinisekisa ukuthi ngabe inhlanganisela yesikhala sendawo yokuhlangana, ukubukeka, izici zombala nezinye izinto ezisebenzayo zemikhiqizo esanda kuklanywa inembile futhi inengqondo, noma ukukhombisa imikhiqizo kumakhasimende ukuthola imibono yamakhasimende noma ukuqashelwa kwemakethe.

Umjikelezo wempilo yomkhiqizo uqala ngokudizayina uphele emakethe. Idizayini yomkhiqizo ichaza ukusebenza, ukubukeka nokwethembeka kwemikhiqizo. Nquma inqubo nezindleko zomkhiqizo. Ukwakhiwa komkhiqizo kungumsebenzi onzima, ohlobene nempumelelo yawo wonke umkhiqizo. Kusukela ekwakhiweni komkhiqizo kuye ekukhiqizweni kokugcina okukhulu, noma yiluphi uhlobo lomkhiqizo oluhloselwe ukukhiqizwa ngobuningi ludinga ukutshala imali eningi, isikhathi namandla. Idizayini enhle iyisihluthulelo sempumelelo yomkhiqizo. Ukukhiqizwa kohlobo lomkhiqizo wokuhlaziya, ukuqinisekisa nokwenza ngcono ukwakhiwa komkhiqizo kuyindlela ebalulekile yokuthola ukwakheka okuphelele kwemikhiqizo. Ukukhiqizwa kwebhodi lesandla kungathuthukisa ngempumelelo ijubane lokuthuthukiswa komkhiqizo

Imikhiqizo ejwayelekile yezimboni, efana ne-elekthronikhi, izinto zikagesi, izimoto nezinsiza kusebenza zezokwelapha, zenziwe ngepulasitiki, ngehardware noma ngezinto ze-elekthronikhi. Ukuze ugweme ukungcola okukhulu ekukhiqizeni ngobuningi nokukhiqizwa okubangelwa amaphutha wokuklama, senza amasampula emodeli ngezindleko ezincane ngokusebenzisa imishini, ukwakha i-laser kanye nesikhunta sesikhashana nezinye izindlela zokuhlaziya, ukuhlangana nokuhlola, noma ukuzibonisa kumakhasimende.

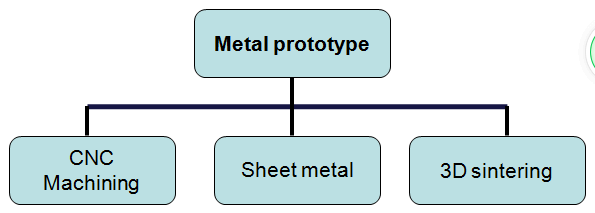

1. Ukukhiqizwa kwensimbi ngesandla imodeli: kunezindlela ezintathu eziyinhloko zokwenza imodeli yengxenye yensimbi

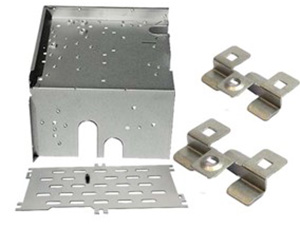

(1). Ishidi lensimbi: ukugoba, ukusika, ukukhipha nokushaya ngesandla noma ngamathuluzi alula. Le ndlela isetshenziselwa ikakhulukazi ukwenziwa kwemodeli yezingxenye zensimbi ezinamapulangwe amancane. Izinto ezisetshenziswayo zifaka insimbi, i-aluminium alloy, ingxubevange yethusi ne-zinc alloy.

(2) i-CNC machining: ukugaya, ukujika, ukugaya, ukukhipha nokumba izinto zensimbi kumathuluzi womshini. Le ndlela isetshenziselwa ukwenziwa kwamamodeli wezingxenye zebhulokhi kanye ne-shaft, kwesinye isikhathi izimbobo noma ukuqedwa kwasendaweni kwamamodeli wensimbi nakho kudinga ukwenziwa ngomshini. Izinto ezisetshenziswayo zifaka insimbi, i-aluminium alloy, ingxubevange yethusi ne-zinc alloy.

(3). Ukuphrinta kwe-Metal laser 3D (sintering): Ukuphrinta kwe-Metal 3D kusetshenziselwa ukukhiqiza izingxenye ezinokuma okuyinkimbinkimbi nezakhiwo okunzima ukukhiqizwa ngomshini nangokulungiswa kwensimbi, njengezinsimbi zenjini, amapayipi amanzi okupholisa okubumba, njll Izinto ezisetshenziswayo zifaka ithuluzi insimbi nensimbi yemartensitic, insimbi engagqwali i-titanium emsulwa ne-titanium alloy, i-aluminium alloy, i-nickel base alloy, i-cobalt chromium alloy ne-copper base alloy

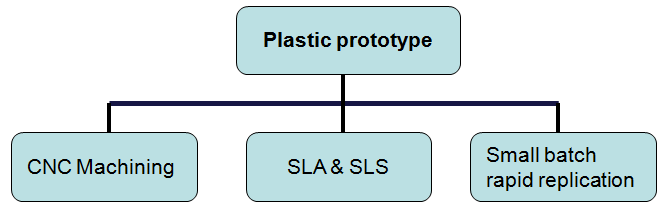

2. Ama-prototypes epulasitiki: kunezindlela ezintathu eziyinhloko zokwenza ama-prototypes epulasitiki:

(1) .CNC machining: okungukuthi, elingenalutho plastic ngomshini phezu ithuluzi umshini. Le ndlela isetshenziselwa ukwenza imishini yegobolondo, ibhlokhi nomzimba ojikelezayo. Kusebenza cishe kuzo zonke izinto zepulasitiki ezilukhuni.

(2). Ukuphrinta ne-sintering ye-Laser 3D (i-SLA ne-SLS): I-SLA isetshenziselwa ukwenza isibonelo sezingxenye eziyinkimbinkimbi ngokubukeka okunzima kwe-CNC nesakhiwo, ikakhulukazi kusetshenziswa izinto ze-ABS ne-PVC ezibizwa ngokuthi i-resin photosensitive. Ukwakhiwa kwe-SLS laser nakho kufaneleka kuma-plastiki we-TPU athambile angenakucutshungulwa yi-CNC, kanye namapulasitiki wobunjiniyela afana nenayiloni.

(3) .Small batch ukuphindaphindeka okusheshayo nge-silica gel isikhunta (kufaka phakathi ukugcwaliswa kokugcwala kanye nomgqomo): le nqubo ithatha imodeli esetshenzwe yi-CNC noma ephrintwe yi-laser 3D njengomgogodla, ithela inani elithile lesikhunta se-silica gel, bese ijova ipulasitiki engamanzi ku-silica gel mold mold. Ngemuva kokuphulukisa, sika isikhunta se-silica gel ukuthola izingxenye zepulasitiki. Izinto ezisetshenziselwa ukwenza izingxenye ziyi-ABS, i-PU, i-PC, inayiloni, i-POM ne-PVC ethambile

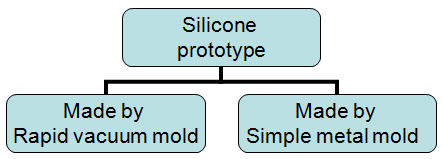

3. Ukwenziwa kwesibonelo kwezingxenye ze-silica gel:

Okwenziwe nge-silica gel kuthambile futhi izinga lokushisa lokuncibilika kwalo liphansi futhi lithambile, ngakho-ke ukuphrinta kwe-CNC noma kwe-laser 3D ngokuvamile akutholakali. Izindlela eziyinhloko zokwenza abicah prototype zingu-vacuum isikhunta kanye nesikhunta esilula sakha.

Ama-prototypes esiwenzele amakhasimende ethu ami kanjena:

Ama-prototypes e-CNC wensimbi

Ama-prototypes wensimbi

Izithombe ze-3D sintering

Ama-prototypes abicah nge-vacuum mold

Izici ze-CNC zepulasitiki

Ama-prototypes wokuphrinta we-Laser 3D

Ama-prototypes epulasitiki ngokugcwaliswa komshini

Prototypes Silicone by isikhunta elula ukwakha

Ukwelashwa komhlaba kwesibonelo

Kubandakanya ukuphrinta kwe-3D, ukucutshungulwa kwe-CNC, ukufakwa ebusweni, ukudweba kanye nokuphrinta kwesilika kwesikrini se-vacuum replica plastic part model.

Kubandakanya izingxenye zensimbi, i-aluminium alloy, i-zinc alloy, ukukhiqizwa kwezingxenye zensimbi engagqwali nokudweba, i-electroplating, i-oxidation, i-PVD nokunye ukwelashwa kwendawo.

IMestech ineqembu lonjiniyela abagxile ekwakhiweni komkhiqizo, behlinzeka ngamabhizinisi amancane naphakathi nendawo kanye namakhasimende ngezinsizakalo zokuma okukodwa komkhiqizo, ukukhiqizwa komkhiqizo, ukukhiqizwa kwesikhunta sepulasitiki nensimbi, ingxenye yokukhiqiza ngobuningi kanye nokufika kwempahla.